Discover a professional 3D printing powder supplier

Metal 3D Printing: Game Changer or Just Cool?

(is metal good for 3d printing)

Metal 3D printing grabs attention. It sounds futuristic. People wonder if it really works well. They want to know if metal is good for making things this way. This blog dives deep into metal 3D printing. We will explore what it is. We will see why it matters. We will learn how it works. We will look at where it’s used. We will answer common questions. Let’s get started.

1. What Exactly is Metal 3D Printing?

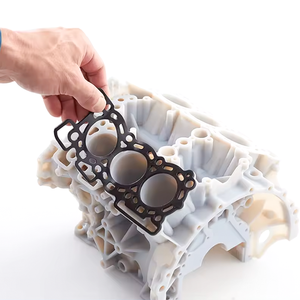

Metal 3D printing builds objects layer by layer. It uses metal powder instead of plastic. A computer controls the whole process. It’s also called metal additive manufacturing. Think of it like building with tiny metal particles. A high-powered heat source melts the powder. The heat source is usually a laser or electron beam. The melted powder fuses together. It cools down and becomes solid metal. Layer by layer, a complete part forms. This happens inside a special machine. The machine is often filled with inert gas. This prevents the metal from oxidizing. Different metals can be used. Common choices include stainless steel, titanium, aluminum, and even tool steel. The result is a solid metal part. It comes straight out of the printer. This is different from plastic 3D printing. Plastic parts are common. Metal parts are strong and durable. They can be used for real-world applications. This makes metal 3D printing exciting for industries.

2. Why Choose Metal for 3D Printing? The Big Benefits

Metal brings special advantages to 3D printing. Strength is a major reason. Metal parts are inherently strong. They handle stress and high temperatures well. Plastic parts often cannot. Durability is another plus. Metal parts last a long time. They resist wear and tear. This is crucial for functional components. Complexity is unlocked with metal 3D printing. It makes intricate shapes possible. These shapes might be impossible with traditional methods. Think of parts with internal channels. Or think of designs with complex lattices. Traditional machining struggles here. Metal printing excels. Customization becomes easy. You can make one unique part. Or you can make a small batch. You don’t need expensive molds. This saves time and money for prototypes. Weight reduction is a big deal. Especially in aerospace and automotive. Metal printing allows lightweight designs. It achieves this without sacrificing strength. Material efficiency is improved. You only use the metal needed for the part. Traditional methods cut away a lot of material. This creates waste. Metal printing minimizes waste. These benefits make metal 3D printing valuable.

3. How Does Metal 3D Printing Actually Work? The Process Explained

The process seems complex. It breaks down into steps. First, a 3D model is created on a computer. This is the digital blueprint for the part. The model is sliced into thin layers. Software handles this step. The sliced data goes to the printer. Inside the printer, a thin layer of metal powder spreads out. A powerful laser or electron beam moves across the powder. It follows the shape of that first slice. The beam melts the powder in precise spots. The melted powder fuses and solidifies. The build platform lowers slightly. Another layer of powder spreads over the first. The laser or beam again melts the new powder. It bonds it to the layer below. This repeats over and over. Layer by layer, the part builds up. The surrounding powder supports the part during printing. After printing, the part is still hot. It is encased in unused powder. The whole chamber cools down. Workers remove the part from the powder. This is called depowdering. The part often needs further heat treatment. This relieves internal stresses. It improves the metal’s properties. Sometimes support structures are needed. These are printed too. They must be removed later. Finally, the part might need machining or polishing. This achieves the final surface finish. The core technology is fascinating.

4. Where is Metal 3D Printing Making Waves? Real-World Applications

Metal 3D printing is not just a lab experiment. It’s solving real problems today. Aerospace is a major user. Aircraft need strong, lightweight parts. Turbine blades, fuel nozzles, and brackets are printed. This reduces weight and improves fuel efficiency. Medical applications are growing fast. Think of custom implants. Hip joints and spinal implants fit patients perfectly. Surgeons use printed surgical guides too. These guides improve accuracy during operations. The automotive industry embraces it. High-performance cars use printed parts. These parts withstand extreme conditions. Formula One teams rely on rapid prototyping. They test new designs quickly. Tooling and manufacturing benefit greatly. Factories print custom jigs and fixtures. These tools hold parts during assembly. Printing them is faster than machining. End-use parts are becoming common. Industries use printed parts directly in products. This happens when quantities are low. Or when the design is highly complex. The energy sector uses it. Oil and gas companies print complex components. These parts survive harsh environments. Even jewelry designers use metal printing. They create intricate pieces impossible by hand. The applications keep expanding.

5. Metal 3D Printing FAQs: Answering Your Burning Questions

(is metal good for 3d printing)

People have many questions about metal printing. Let’s tackle some common ones. Is it expensive? Yes, it usually costs more than plastic printing. The machines are costly. The metal powder is pricey. Post-processing adds expense. However, for complex or custom parts, it can be cost-effective. How strong are the parts? They are very strong. Properly printed parts match traditional metal strength. Sometimes they exceed it. The strength depends on the metal used. It also depends on the printing process. What metals can be printed? Many metals work. Stainless steel grades are popular. Titanium is used for aerospace and medical. Aluminum alloys are common. Nickel alloys handle high heat. Cobalt-chrome is used in dentistry. Even precious metals like gold can be printed. How long does it take? Printing time varies. Small parts might take hours. Larger, complex parts can take days. Post-processing adds more time. It’s not instant. Is it safe? Printing happens inside sealed machines. Operators must handle powders carefully. Proper ventilation and protective gear are essential. Post-processing like sandblasting requires safety measures. Who is using it? Aerospace giants like Boeing and Airbus use it. Medical device companies rely on it. Car manufacturers adopt it. Many smaller engineering firms offer printing services. It’s becoming more accessible.