Discover a professional 3D printing powder supplier

Metal Magic: Your Guide to 3D Printing in Metal

(metal 3d printing?)

Metal 3D printing sounds like science fiction. Imagine building complex metal parts layer by layer. No giant molds. No piles of metal shavings. Just digital designs turning into solid metal objects. This technology is real. It is powerful. It is changing how we make things. Let’s explore this fascinating world.

1. What is Metal 3D Printing?

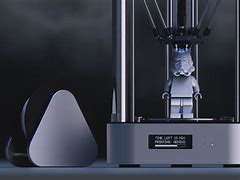

Forget plastic trinkets. Metal 3D printing creates solid metal parts. Think of it like building with digital LEGO. A computer slices a 3D model into thin layers. The printer then builds the object one layer at a time. It fuses metal powder or wire together. This fusion happens using intense heat. Lasers or electron beams melt the metal precisely. Layer upon layer stacks up. Slowly, a complete metal part emerges. It is not just a model. It is a functional piece. It can be as strong as parts made the old way. Different metals work too. Titanium for aerospace. Stainless steel for tools. Even gold for jewelry. The possibilities are wide.

2. Why Choose Metal 3D Printing?

Why pick metal 3D printing over traditional methods? It offers unique advantages. Design freedom is huge. You can make shapes impossible with machining or casting. Think of intricate lattices inside a part. Think of complex internal channels for cooling. These designs save weight. They improve performance. Customization is easy. Need one special part? Print it. Need ten slightly different versions? Print them. No expensive tooling changes. Prototyping speeds up dramatically. Test a new design fast. Iterate quickly. Reduce wasted material. Only use the metal needed for the part itself. Small production runs become economical. Repairing high-value parts is possible. Add material exactly where it’s worn. This technology unlocks new potential.

3. How Does Metal 3D Printing Work?

Several methods exist. Two are common. Powder Bed Fusion is popular. A thin layer of fine metal powder spreads across a build platform. A high-power laser or electron beam scans the layer. It melts the powder exactly where the part needs material. The platform lowers slightly. Another powder layer spreads. The laser melts again. This bonds the new layer to the one below. This repeats until the part is complete. Surplus powder supports the part during printing. Afterward, this powder is removed and reused. Directed Energy Deposition is different. Here, a nozzle deposits metal powder or wire directly. A laser or electron beam melts it at the point of deposition. Think of it like high-tech welding. This method is good for adding material to existing parts. It is good for building large structures. Both methods require controlled environments. Often inert gases are used. This prevents the hot metal from oxidizing. After printing, parts usually need finishing. Support structures are removed. Surfaces might be polished. Heat treatment often strengthens the metal.

4. Where is Metal 3D Printing Used?

This technology shines across industries. Aerospace loves it. Weight savings are critical. Complex, lightweight parts boost fuel efficiency. Turbine blades with internal cooling channels are printed. Satellite components benefit too. Medical applications grow fast. Custom implants fit patients perfectly. Think titanium hip joints or skull plates. Dental crowns and bridges are printed. Surgical tools get unique designs. The automotive sector adopts it. High-performance cars use printed parts. Custom fixtures aid manufacturing. Prototyping happens faster. Tooling gets cheaper. Even consumer goods see benefits. High-end bicycles have printed components. Unique jewelry pieces are crafted. Industrial machinery uses printed parts for repair. Heat exchangers with complex internal designs perform better. The applications keep expanding.

5. Metal 3D Printing: Your Questions Answered

(metal 3d printing?)

Many people have questions. Here are common ones. How strong are printed metal parts? Very strong. Properly printed and treated parts match traditionally made parts. Sometimes they are stronger. Are the parts dense? Yes. Good printing produces fully dense metal. No inherent weakness. What about surface finish? As-printed surfaces can be rough. Post-processing like machining or polishing smooths them. Is it expensive? The machines cost a lot. Material costs are higher than bulk metal. But for complex or custom parts, it can be cost-effective. You save on tooling and waste. How big can parts be? It depends on the printer. Some make small, precise parts. Others build larger items. Combining parts is possible too. Can I print at home? Not really. Metal printers need special facilities. They require safety measures. They need controlled environments. The barrier to entry is high. It is mainly an industrial technology.