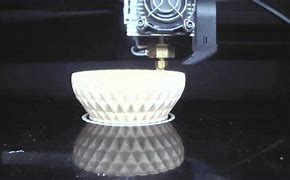

Discover a professional 3D printing powder supplier

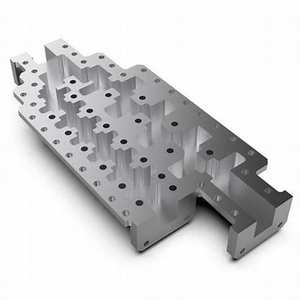

(Process of Stainless Steel Powder Metallurgy)

Stainless steel powder metallurgy, as the name implies, is stainless steel

manufactured by powder metallurgy. Compared with the stainless steel produced by

the traditional melting process, it has the advantages of producing parts close

to net shape, high dimensional accuracy, high material utilization, and uniform

structure.

The process flow of stainless steel powder metallurgy is to prepare powder

-> forming -> sintering

1. Powder preparation: It is the first step in the production of stainless

steel by powder metallurgy. It can be water atomization. The molten stainless

steel is discharged from the nozzle hole, blown and solidified with

high-pressure water to obtain stainless steel powder. The bulk density of water

atomized stainless steel powder is 2.5~3.2 g/cm3. It can also be gas

atomization. The bulk density of the high-pressure nitrogen atomized powder is

4.8 g/cm3, and the oxygen content of the powder is less than 10-4. The rotating

electrode powder method can also be used to produce spherical stainless steel

powder.

2. Forming: The forming pressure is 550~830 MPa.

3. Sintering: Because the alloy elements in stainless steel are easy to

oxidize, it must be sintered in a protective atmosphere with extremely low

oxygen content. If hydrogen or decomposed ammonia is used as the protective

atmosphere, the dew point should be -45~-50°C. Vacuum sintering can also be

used, and the sintering temperature is 1120~1150℃. These stainless steel powders

can also be packed into the sheath, vacuum-sealed, cold isostatic pressing, and

then hot isostatic pressing to densify the material. The process parameters are

1050°C and the pressure is 2 kPa.

Compared with ordinary cast and forged stainless steel, stainless steel

powder metallurgy has small segregation of alloy elements, fine grain size, fine

and even distribution of impure inclusions, and higher mechanical properties and

corrosion resistance. In particular, high-nitrogen stainless steel produced by

powder metallurgy has a much lower cost than high-pressure smelting. At the same

time, powder metallurgy high-nitrogen stainless steel has a series of excellent

properties and has a very broad application prospect.

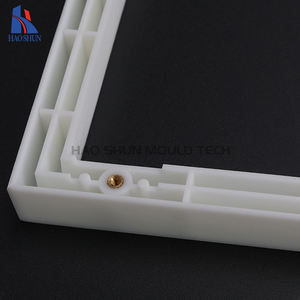

The stainless steel prepared by the stainless steel powder metallurgy method

can refine the microstructure and reduce the segregation of alloying elements,

thereby improving the performance of the material. In addition, it can save raw

materials and energy consumption, and achieve low-carbon, green and

environmental protection. It has been widely used in machinery, chemical

industry, shipbuilding, automobile, instrumentation and other industries.

About 3dprintingpassion

3dprintingpassion is a trusted global chemical material supplier & manufacturer with

over 12 years experience in providing super high-quality chemicals and

Nanomaterials. The company export to many countries, such as USA, Canada,

Europe, UAE, South Africa, Tanzania,

Kenya,Egypt,Nigeria,Cameroon,Uganda,Turkey,Mexico,Azerbaijan,Belgium,Cyprus,Czech

Republic,Brazil, Chile, Argentina, Dubai, Japan, Korea, Vietnam, Thailand,

Malaysia, Indonesia, Australia,Germany, France, Italy, Portugal etc. As a

leading nanotechnology development manufacturer, 3dprintingpassion dominates the market.

Our professional work team provides perfect solutions to help improve the

efficiency of various industries, create value, and easily cope with various

challenges. If you are looking for Stainless steel powder, please send an email to:

sales2@nanotrun.com

(Process of Stainless Steel Powder Metallurgy)