Discover a professional 3D printing powder supplier

Title: Metal Magic: Can Your 3D Printer Really Print Steel? .

(the most advanced 3d printer 3d printed metal ?)

Main Item Keywords: 3D printer, 3D printed steel.

1. What is 3D Printed Steel? .

Forget plastic trinkets and toy figurines. We’re talking about building real, solid metal objects. Layer by layer. Straight from a computer system file. This is 3D printed steel. It seems like sci-fi. It feels like magic. Yet it’s extremely real manufacturing today. Think about it like welding. Yet incredibly precise. Regulated by a computer. As opposed to melting large pieces of steel with each other, an equipment constructs the things from tiny fragments of metal powder. Or carefully down payments liquified steel. The outcome? Facility shapes. Shapes impossible to make with conventional cutting or spreading. Solid, useful steel components. Gears, engine components, customized clinical implants, also aerospace components. This isn’t your enthusiast’s plastic printer. This is industrial-grade production. It uses effective lasers, electron light beams, or jets of binder. It integrates metal powder into strong forms. It unlocks layout freedom formerly unthinkable in metalwork.

2. Why Print Steel? Why Not Simply Maker It? .

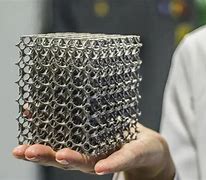

Excellent inquiry. Standard approaches like machining or casting work well. They make most metal parts we use. So why trouble printing steel? The solution depends on complexity and waste. Machining carves shapes out of strong blocks. This develops a great deal of scrap steel. Occasionally more scrap than the last part. Casting needs molds. Mold and mildews are expensive and take some time to make. Printing metal includes product just where required. This substantially minimizes waste. It’s more product reliable. However the larger win is design freedom. Visualize a cooling channel inside a rocket engine nozzle. Twisting and turning like a serpent. Difficult to equipment. Impossible to cast. However easy to publish. Lightweight frameworks. Motivated naturally. Strong honeycomb forms inside strong parts. Only metal makes this sensible. Required a personalized, one-off clinical implant? Perfect suitable for an individual. Printing is much faster and less expensive than conventional custom tooling. It allows rapid prototyping of steel parts. Examining layouts rapidly. It allows mass customization. Distinct parts made effectively. It pushes the boundaries of what steel components can do.

3. Just How Does Steel 3D Printing Really Function? .

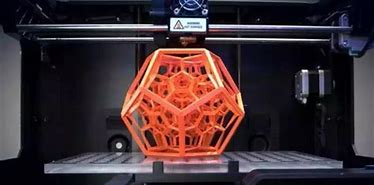

The magic happens in numerous ways. Various technologies exist. One of the most usual kind is called Powder Bed Combination. Image this. A thin layer of great metal powder spreads across a construct platform. A powerful laser scans the powder. It follows the form of one cross-section of your digital style. Where the laser hits, the metal powder melts and integrates. Strengthening into your part. The system lowers somewhat. An additional layer of powder spreads. The laser scans again. Fusing this brand-new layer to the one listed below. This repeats. Layer by layer. Constructing the item upwards inside a chamber full of inert gas. Another method is Binder Jetting. Right here, a print head jets a fluid binder onto a powder bed. Binding the bits with each other. Producing a “eco-friendly” part. This environment-friendly part is breakable. It then enters into a heating system. The heating system sinters it. Heating it to bond the metal bits. Making it solid and strong. Directed Energy Deposition (DED) is various. It feeds metal powder or wire right into a thaw swimming pool. Created by a laser, electron beam, or plasma arc. The product melts as it’s deposited. Building up the component. Like high-precision welding. Each approach has staminas. Powder bed combination excels at fine details. Binder jetting is quicker for larger parts. DED is wonderful for adding steel to existing things or huge repair services.

4. Real-World Applications: Where is Printed Metal Made Use Of? .

This technology isn’t simply lab experiments. It’s materializing things. Vital points. Look up at the sky. Aerospace giants utilize it. They print light-weight, intricate fuel nozzles for jet engines. Decreasing weight saves gas. Printed parts hold up against extreme heat and stress. Inside the body. Surgeons make use of custom-printed titanium implants. Created from patient scans. Completely fitting a jawbone or hip outlet. Biocompatible steels integrate with bone. Automotive firms print prototypes swiftly. They check new engine designs quickly. Some also print high-performance parts for auto racing or minimal version cars. The energy market benefits. Facility parts for turbines. Oil and gas parts that stand up to rust. Even the tooling industry utilizes it. Making injection mold and mildews with complex cooling networks. Cooling down plastic quicker. Quickening production. Jewelers produce intricate, impossible-to-cast designs. Musicians sculpt steel in brand-new methods. The applications grow regularly. Anywhere complicated, solid, light-weight, or custom-made steel components are needed. Printing supplies a service.

5. Metal 3D Printing FAQs: Your Concerns Responded to .

Many people have concerns. Here are some typical ones:.

Is 3D published metal strong? Yes. Extremely strong. Often as solid, or perhaps stronger, than typically made steel parts. The process permits dense, well-bonded frameworks. Properties can match or exceed cast steel. Often approaching forged metal strength. Post-processing like warmth therapy typically boosts stamina further.

What metals can be published? Numerous common design steels function. Titanium alloys are preferred. Especially Ti-6Al-4V. Known for stamina and biocompatibility. Stainless-steel qualities (like 316L) are widely used. Light weight aluminum alloys use lightweight alternatives. Nickel-based superalloys deal with severe heat. Device steels, cobalt-chrome, copper, and even rare-earth elements like silver and gold can be printed. New materials are regularly being developed.

Is it expensive? It can be. The printers set you back a whole lot. Metal powder is costly. The process takes some time and power. Nevertheless, for facility components or small sets, it can be more affordable. It prevents pricey tooling. Lowers material waste. Conserves time in advancement. The worth often originates from allowing styles difficult or else. Costs are decreasing as innovation developments.

How smooth is the surface area? Straight off the printer? It depends on the innovation. Powder bed combination components often have a somewhat harsh, rough surface area. Like fine sandpaper. Binder jetting components prior to sintering can be delicate. Post-processing is usually needed. Strategies like machining, grinding, polishing, or shot peening smooth the surface area. Attain the required finish.

(the most advanced 3d printer 3d printed metal ?)

Can I do this in your home? Not genuinely. Not yet. Steel 3D printers are complex, big makers. They require considerable power. Need specialized facilities. Dealing with great metal powder requires safety measures. Inert gas systems are essential. Post-processing calls for heating systems and machining tools. It’s industrial modern technology. Enthusiast systems for real metal printing do not exist. Some desktop equipments make use of metal-filled plastic. However the result isn’t solid steel. Real steel printing stays a factory-floor procedure.