Discover a professional 3D printing powder supplier

Metal Magic: Which 3D Printer Kits Can Handle Real Metal Filament?

(what 3d printer kits can print metal filament)

The dream of printing solid metal parts right on your desk is no longer science fiction. But navigating the world of 3D printers claiming metal capability is tricky. Not all machines are equal. This guide cuts through the hype. We focus on the specific kits ready for real metal filament. We explain how they work, why you might want one, and what you can truly build.

Main Product Keywords: 3D Printer Kits, Metal Filament

1. What Are Metal Filament 3D Printer Kits?

Metal filament 3D printer kits are build-it-yourself machines. They are designed specifically for printing special filaments. These filaments contain a high percentage of real metal powder. Think stainless steel, copper, bronze, even iron. The printer itself needs specific upgrades. A standard plastic printer won’t cut it. The key difference is the hot end. Metal filaments are abrasive. They wear down standard brass nozzles fast. These kits use hardened steel nozzles. Sometimes even ruby or diamond-tipped nozzles. The extruder also needs to be robust. It must push this gritty material consistently. The build plate often needs higher temperatures too. This ensures the metal-filled plastic sticks properly during printing. The frame needs to be rigid. Metal prints are denser and heavier than plastic. The kit must handle this without wobbling. The goal is a machine built tough enough for metal dust.

2. Why Choose a Kit for Metal Filament Printing?

Industrial metal 3D printers cost a fortune. They often use lasers and powdered metal. That’s out of reach for most hobbyists and small workshops. Metal filament kits offer a different path. They are much more affordable. You get the ability to create metal-like parts. The printed objects have real metal inside. After printing, you need a post-processing step. This is sintering or infusing with a binder. This step burns away the plastic binder. It fuses the metal particles. The result is a solid metal part. The kits are accessible. You build them yourself. This saves money. You also learn how the machine works. This is valuable for troubleshooting. The running costs are lower. Metal filament is expensive. But it’s cheaper than industrial metal powder systems. These kits let you experiment with metal prototyping. They are great for functional parts, art, or custom tools. They bridge the gap between plastic printing and true industrial metal.

3. How Do These Kits Print Metal Filament?

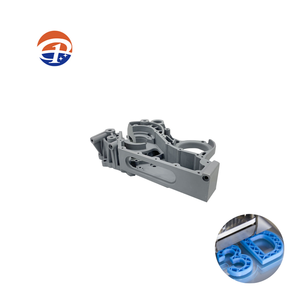

The process starts like regular FDM 3D printing. But the materials and settings are critical. The filament looks like plastic. It feels heavy. Inside, it’s packed with fine metal powder bound by polymer. The printer heats this filament in its hardened hot end. The temperature must be precise. It needs to melt the plastic binder. The metal particles stay solid. The molten mixture gets extruded layer by layer. The metal powder gives the print its weight and texture. But right off the printer, it’s not solid metal. The plastic binder holds the metal particles together. Think of it like a green ceramic part before firing. This “green state” part is fragile. It can be sanded or drilled carefully. The real magic happens next. Post-processing transforms it. The main methods are sintering or infusion. Sintering involves heating the part in a special furnace. This burns away the plastic. It fuses the metal particles into a solid mass. The part shrinks significantly. Metal infusion is different. The printed part gets put into a container with pure metal powder. It’s heated. The molten metal wicks into the porous printed part. This fills the voids. It creates a denser, stronger metal object. The kit handles the printing. You need extra equipment for the final metal conversion.

4. Applications: What Can You Make With Metal Filament Kits?

The possibilities are exciting. You can create strong, functional metal parts. Think custom wrenches, jigs, or replacement brackets. These parts withstand more force and heat than plastic. Artistic creations gain a new dimension. Sculptures have real weight. They feel cold like metal. You can achieve unique metallic finishes. These finishes can be polished, patinated, or aged. Jewelry makers benefit. You can print intricate rings, pendants, or charms. After sintering, they become solid metal. Hobbyists restore old machines. They print missing metal components. Model makers build detailed metal parts for trains or planes. The thermal properties are useful. Copper-filled filament, after processing, conducts heat well. This is good for custom heatsinks or heat exchangers. Tool handles get a metal core for extra strength. The key is design freedom. You can create complex shapes. These shapes would be difficult or expensive to machine traditionally. You make prototypes that look and feel like metal. You produce small batches of custom metal items.

5. Metal Filament Kits: Essential FAQs

Q: Can I use any 3D printer for metal filament?

No. Standard printers use brass nozzles. Metal filament destroys brass nozzles quickly. You need a kit designed for abrasives. It must have a hardened nozzle and a tough extruder.

Q: Is the printed part solid metal right away?

No. The part straight off the printer is a composite. It has metal powder in a plastic binder. It feels heavy. It looks metallic. But it’s not solid metal. You need sintering or metal infusion to make it solid metal.

Q: Do I need special safety gear?

Yes. Metal filaments create fine dust when printing. This dust can be inhaled. Wear a good respirator mask. Work in a well-ventilated area. Metal powder dust can be hazardous. Handle it carefully.

Q: How strong are the final metal parts?

Strength depends on the metal powder. It depends on the filament brand. It depends on the post-processing method. Sintered stainless steel parts can be quite strong. They are suitable for many functional uses. They are generally not as strong as forged or machined steel. But they are much stronger than plastic.

Q: What are the main challenges?

(what 3d printer kits can print metal filament)

Printing requires slow speeds. It needs high nozzle temperatures. Warping can be a problem. Bed adhesion is critical. The post-processing step (sintering/infusion) needs extra equipment. This equipment is expensive. It requires careful control. Shrinkage during sintering changes the final size. You must design for this. Metal filament itself is costly.