Discover a professional 3D printing powder supplier

That’s Actually Publishing Metal? The Large Gamers in 3D Steel Printing Disclosed .

(what companies use 3D metal printing)

The whir of lasers thawing steel powder. The sluggish develop of complicated components layer by layer. This isn’t sci-fi anymore. 3D steel printing is transforming how firms develop things. It’s scooting from labs and models onto. Big names are using it. Little pioneers are pushing it even more. This tech is altering sectors. Let’s see who’s leading the cost and why it matters.

1. What is 3D Steel Printing? .

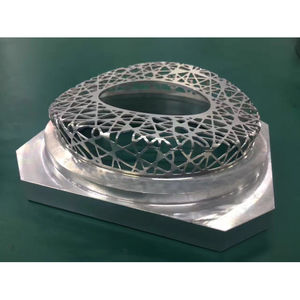

Fail to remember plastic ornaments. 3D steel printing builds real, solid steel parts. It makes use of effective lasers or electron beams. These heat resources melt fine metal powder. The powder merges together exactly. The machine includes layer after layer. It constructs the part straight from a digital design file. No demand for mold and mildews or removing material. This is additive production. Usual names consist of Direct Metal Laser Sintering (DMLS), Discerning Laser Melting (SLM), and Electron Beam Of Light Melting (EBM). Various approaches fit various metals and goals. The result is a strong steel item. It can be unbelievably complicated. Shapes impossible to make any other way come to be feasible. Believe detailed cooling networks inside engine parts. Believe light-weight latticework frameworks. This freedom is a game-changer.

2. Why Companies Pick 3D Steel Printing .

Business aren’t embracing this tech for fun. It resolves genuine troubles. One big reason is design freedom. Engineers can create components maximized for efficiency. They neglect old production limitations. Required complex interior functions? Not a problem. Want a solitary part instead of 10 welded with each other? Easy. This brings about lighter parts. Weight cost savings are big in aerospace and cars. Lighter airplanes use less fuel. Lighter cars and trucks go farther on a charge. More powerful parts are another advantage. The printing process allows new alloys. It develops great microstructures usually stronger than cast metal. Speed is essential also. Prototyping takes place much faster. Style adjustments are straightforward electronic tweaks. Firms examination ideas swiftly. They obtain items to market sooner. For low-volume manufacturing, it’s usually cheaper. No expensive tooling required. Custom or extra components become affordable. Publishing one unique part costs the like publishing a thousand similar ones. This adaptability is effective.

3. How 3D Steel Printing In Fact Functions .

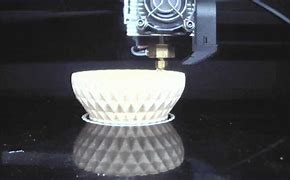

The process might seem like magic. It’s accurate design. It starts with a 3D computer system model. Software program slices this model into slim layers. Inside the printer, a great bed of steel powder waits. A recoater spreads a thin layer of powder. A high-power laser or electron beam scans the layer. It complies with the shape of that very first piece. The energy melts the powder fragments. They fuse together and to the layer below. The build platform decreases a little. The recoater spreads fresh powder. The laser scans the next slice. This repeats. Layer by layer, the component grows inside the powder bed. Assistance structures hold overhanging components. They protect against warping. After printing, the part cools down inside the equipment. Employees eliminate the excess powder. They removed the assistances. The component usually requires completing. Warm treatment reinforces it. Machining smooths surface areas. Assessment guarantees high quality. Then it’s ready for usage.

4. Real-World Applications: That Makes Use Of 3D Steel Printing? .

This technology is not simply for labs. Major companies depend on it daily. Aerospace giants blaze a trail. GE Aviation publishes fuel nozzles for jet engines. These nozzles are lighter and stronger. They combine several components right into one. Airplane and Boeing print facility braces and cabin components. Weight savings here imply massive fuel decreases. The medical field accepts it. Stryker and Zimmer Biomet print custom hip and knee implants. These implants fit clients perfectly. Dental laboratories print crowns and bridges quick. Automobile makers like BMW and Volkswagen utilize it. They publish models swiftly. They make custom jigs and tools for production line. Some print high-performance parts for limited-edition cars and trucks. Power business use it. Siemens publishes gas generator blades with intricate air conditioning channels. These blades stand up to extreme heat better. Also durable goods advantage. Business print special fashion jewelry styles. They make personalized bike components. Heavy sector prints extra components as needed. This decreases maker downtime substantially. The applications maintain expanding.

5. 3D Metal Printing FAQs .

(what companies use 3D metal printing)

Individuals often ask similar inquiries. Is 3D printed steel strong sufficient? Yes. Correctly published and refined components fulfill strict industry requirements. Aerospace and medical implants prove this day-to-day. Is it costly? Expenses are falling. For facility, light-weight, or custom parts, it’s typically more affordable general. You save on tooling, assembly, and product waste. What metals can be published? Several common alloys function. Titanium is prominent for its toughness and agility. Light weight aluminum alloys are commonly used. Stainless-steels provide good deterioration resistance. Nickel superalloys deal with extreme warmth. Also precious metals like gold get published. Exactly how huge can parts be? Printers keep obtaining larger. Industrial machines can print parts over a meter long. Smaller parts are a lot more typical currently. Huge components may be published in sections and signed up with. What about surface finish? Printed components have a harsh surface area. They generally need machining or sprucing up. This includes price however achieves the needed coating. Is it risk-free? Publishing with metal powders needs cautious handling. Specialist systems take care of dirt and fumes well. Safety and security procedures are strict.