Discover a professional 3D printing powder supplier

Title: That’s Getting on the 3D Steel Printing Bandwagon? (Hint: It’s Not Simply Geeks!) .

(what industries use 3D metal printing)

Main Search Phrase: 3D Metal Printing.

1. Exactly What is 3D Steel Printing? .

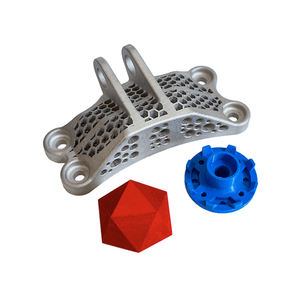

Fail to remember plastic trinkets. 3D steel printing, additionally called metal additive manufacturing (AM), develops actual, solid steel components layer by layer. It utilizes powerful lasers or electron beams. These light beams thaw great steel powder, exactly following an electronic plan. Think about it like welding, yet regulated by a super-smart computer. The device adds material only where needed, unlike removing material from a huge block. This develops complex shapes often impossible any other way. It turns digital layouts right into substantial, functional steel objects. The process begins with a 3D design cut into slim layers. The printer after that builds each layer diligently. Products range from typical stainless-steel to exotic titanium and superalloys. It’s production, simply shook up.

2. Why is 3D Steel Printing Such a Big Offer? .

This modern technology resolves huge issues. Initially, it makes exceptionally intricate components feasible. Think about complex air conditioning networks inside a rocket engine nozzle. Machining that is a problem, commonly difficult. 3D printing does it quickly. Second, it makes use of product extremely successfully. Typical machining often removes over 80% of the metal block. Printing makes use of practically just the steel needed for the last component. This saves costly product and decreases waste. Third, it allows quick prototyping. Engineers can design a part, print it overnight, test it the following day. This quickens growth greatly. 4th, it allows mass modification. Need a special medical implant flawlessly matching an individual’s bone? Printing can do it cost-effectively. Fifth, it streamlines assemblies. You can publish several components combined into one stronger, lighter element. This reduces assembly time and possible failing factors. These advantages are game-changers.

3. Exactly How Does 3D Steel Printing In Fact Work? .

Several methods exist, but 2 dominate. The initial is Powder Bed Combination (PBF). Picture a slim layer of metal powder spread throughout a build plate. A high-power laser or electron light beam checks the powder surface. It melts the powder specifically where the component’s cross-section must be. The build plate decreases a little. One more layer of powder is spread out. The laser melts again, bonding to the layer below. This repeats thousands of times up until the component is total. Surrounded by extra powder, the part is after that removed. The second significant approach is Directed Energy Deposition (DED). Here, metal powder or cord is fed through a nozzle. A focused energy source (laser, plasma arc) melts the material as it’s transferred onto a surface, building up the component. After printing, components typically require completing. This consists of removing assistance frameworks, heat treatment for stamina, and surface polishing. It’s a digital craft.

4. 3D Metal Printing Applications: Where is it Making Waves? .

This tech is transforming industries right now. Aerospace is a substantial adopter. Business publish light-weight, super-strong parts for jet engines, rockets, and satellites. Believe gas nozzles, wind turbine blades, and architectural brackets. Weight cost savings right here suggest huge fuel efficiency gains. The clinical field loves it as well. Surgeons use patient-specific 3D printed titanium implants for hips, knees, and cranial repair services. Dental laboratories print crowns and bridges. Biocompatible metals integrate flawlessly with bone. Automotive firms utilize it for prototyping quick. They also print high-performance parts for race automobiles and custom-made components for high-end vehicles. Tool and die manufacturers develop conformal cooling channels inside molds. This considerably reduces shot molding cycle times. Energy firms print complex components for oil & gas removal and power generation turbines. Even fashion jewelry designers currently utilize it to create complex metal pieces difficult by hand. Its reach is vast and growing.

5. 3D Steel Printing FAQs: Your Burning Questions Answered .

Is it really solid? Absolutely. Effectively printed and processed metal components fulfill or exceed the stamina of generally made parts. They are used in critical aerospace and clinical applications. Quality assurance is essential.

How costly is it? The equipments and products set you back even more in advance than basic machining devices. However the cost savings originate from much less waste, faster prototyping, complicated part combination, and performance gains. For the right part, it’s extremely cost-efficient.

What metals can be printed? A vast array! Common ones include stainless steels (316L, 17-4 PH), titanium alloys (Ti-6Al-4V), aluminum alloys (AlSi10Mg), nickel-based superalloys (Inconel 718, 625), cobalt-chrome, and also precious metals like gold and platinum.

For how long does it take to print a part? It depends completely on the size and intricacy. Small components could take hours. Big, thick parts can take days. It’s usually slower per component than automation techniques like spreading, yet quicker for one-offs and prototypes.

(what industries use 3D metal printing)

Are there dimension limitations? Yes, but they are broadening. Industrial printers can now build components meters long. However, the develop chamber dimension of the details printer specifies the optimal part dimensions for a solitary print. Larger assemblies can be published in items and joined.