Discover a professional 3D printing powder supplier

** Steel Magic: Just How 3D Printing is Building the Future **.

(what is 3d metal printing)

Envision a machine that can transform digital dreams into strong metal items. No hammers, no molten heaters, no gigantic molds. This isn’t sci-fi. It’s 3D metal printing, a modern technology reshaping exactly how we construct whatever from rocket engines to fashion jewelry. Allow’s dive into just how it works and why it’s transforming the game.

Initially, consider typical metalworking. For centuries, humans have melted, cast, and carved steel. These methods function, however they’re sluggish, wasteful, and limited by the devices. Currently image a procedure where steel components grow layer by layer, like a modern ceramic wheel assisted by a computer system. That’s 3D metal printing.

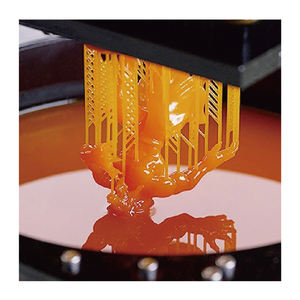

The core concept is simple. An electronic design is sliced right into ultra-thin layers. The printer reviews these layers and develops the things one speck of metal at a time. Yet the magic remains in the information. Most metal printers make use of lasers or electron beam of lights to fuse powdered steel into strong forms. The powder is finer than beach sand, and the warm source is accurate sufficient to bond microscopic fragments with each other.

Below’s the awesome part. The printer does not simply adhere to a fixed blueprint. It can readjust in real-time. Sensors keep track of temperature level and framework, tweaking the laser’s power or speed to take care of mistakes. This indicates fewer stopped working prints and more powerful end products.

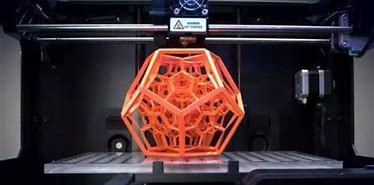

Why does this matter? For starters, 3D steel printing unlocks forms that were as soon as difficult. Typical approaches have problem with hollow structures, intricate latticeworks, or organic contours. A 3D printer does not care. It can develop a honeycomb lattice inside a generator blade to make it lighter, or craft a clinical dental implant that completely matches a patient’s bone structure.

Rate is another win. Prototyping a steel component utilized to take weeks. Currently, a developer can send a data to a printer and hold the finished item in days. This is significant for industries like aerospace or automobile, where faster iterations indicate prospering of rivals.

Prices are dropping too. Early steel printers were million-dollar makers. Today, smaller designs are reaching workshops and labs. The products are getting more affordable as even more firms generate metal powders. This isn’t simply for titans like NASA or BMW any longer. A dental professional can publish a titanium crown. A hobbyist can craft a customized bike part.

Yet it’s not all plain sailing. Publishing with steel is difficult. The heat can warp slim sections. Some steels, like light weight aluminum, reflect lasers and need special delivery. Engineers are still figuring out exactly how to ensure every layer bonds perfectly.

Then there’s the inquiry of strength. A published metal component isn’t constantly as challenging as one forged in a factory. Post-processing like heat therapy or polishing is usually required. Still, progression is fast. New alloys and printing strategies are closing the space.

Take a look around, and you’ll detect 3D metal printing at work. SpaceX uses it for rocket engine parts. Medical professionals utilize it for patient-specific implants. Artists utilize it for sculptures that twist and contour in ways steel should not. The innovation is still young, however its potential feels limitless.

(what is 3d metal printing)

The next time you see a streamlined metal gizmo or a futuristic automobile component, bear in mind: it could have begun as a heap of powder and a beam. 3D metal printing isn’t simply making things. It’s redefining what’s possible.