Discover a professional 3D printing powder supplier

Metal 3D Printing: Why Isn’t It Everywhere Yet?

(what is holding metal 3d printing back)

Metal 3D printing promises amazing things. Think complex parts impossible to make otherwise. Think lighter, stronger components. Think customized designs made quickly. But look around. You don’t see metal printers on every factory floor. They aren’t in every workshop. So what’s the deal? What’s slowing down this fantastic technology? Let’s dive in and see the real hurdles facing metal additive manufacturing.

1. What is Metal 3D Printing?

Think about your regular paper printer. It puts ink on paper to make words or pictures. Metal 3D printing is kinda like that. But instead of ink, it uses metal. Instead of paper, it builds objects layer by layer. A computer controls the whole thing. It tells the printer exactly where to put tiny bits of metal powder or wire. Layer by layer, a solid metal object forms. This process is called additive manufacturing. It adds material to create the shape. This is different from cutting away metal, like machining. It opens doors to wild new designs. Parts can have internal channels. They can have complex lattices. They can be shapes that were simply impossible before.

2. Why Isn’t Metal 3D Printing Used More?

Metal 3D printing sounds perfect. But reality isn’t so simple. Several big things hold it back. First, the cost. The printers themselves are expensive. We’re talking hundreds of thousands of dollars. Even millions for some models. The metal powders used are also pricey. They need to be very pure and very fine. Special gases are often needed too. This makes the whole process costly. Second, speed. Building a metal part layer by layer takes time. Sometimes a long time. For large parts, it might take days. This is slower than many traditional methods for big production runs. Third, skills. Running these machines isn’t easy. You need trained operators. You need engineers who understand the design rules. You need people who know how to fix problems. Finding these experts can be tough. Fourth, consistency. Getting the exact same result every time is challenging. Small changes can affect the final part’s strength. Making sure every part is perfect requires careful control. Fifth, finishing. Parts often come out rough. They might need machining or polishing afterward. This adds extra steps and cost. These factors together make it hard for companies to switch overnight.

3. How Does Metal 3D Printing Work?

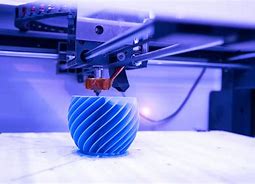

Several ways exist to print metal. Two main methods are popular now. The first is Powder Bed Fusion. Think of a thin layer of metal powder spread on a platform. A powerful laser or electron beam then zaps the powder. It melts the powder exactly where the design says. This makes one solid layer. Then, more powder is spread on top. The laser melts the new layer. It also bonds it to the layer below. This repeats until the part is done. Any unmelted powder supports the part during printing. Afterward, you dig the part out of the powder. The second method is Directed Energy Deposition. Here, metal powder or wire is fed into a nozzle. A laser or plasma arc melts the material right at the nozzle tip. The melted metal is deposited onto a surface. The nozzle moves, building up the part layer by layer. This method is often used for adding material to existing parts. It’s good for repairs. Both methods need controlled environments. They often use inert gases like argon. This prevents the hot metal from reacting with oxygen.

4. Where is Metal 3D Printing Used Today?

Despite the hurdles, metal 3D printing is finding its place. It shines in specific areas. Aerospace is a big user. Think jet engines and rockets. These need incredibly strong, lightweight parts. Metal printing makes complex fuel nozzles and turbine blades. Parts that are lighter but just as strong. This saves fuel. Medical is another key area. Think custom implants. A hip joint made perfectly for one patient. Dental crowns and bridges. Surgical tools with unique shapes. The ability to customize is huge here. Tooling is also benefiting. Companies print molds for plastic injection molding. These molds have internal cooling channels. This makes the molding process faster. High-end automotive uses it too. For race cars. For custom parts in luxury vehicles. Prototyping is another area. Designers can quickly print a metal prototype to test. This speeds up development. While not for everything yet, it solves tough problems in these fields.

5. FAQs About Metal 3D Printing

People have lots of questions about this technology. Here are some common ones.

Is it strong? Yes! Properly printed metal parts can be very strong. Often as strong as parts made the traditional way. Sometimes even stronger. But it depends on the material and the process used.

What metals can be printed? Many common metals work. Titanium is popular. It’s strong and lightweight. Stainless steel is widely used. Aluminum alloys are common too. Nickel superalloys handle extreme heat. Even precious metals like gold can be printed.

How big can the parts be? Size depends on the printer. Small printers fit on a desk. They make tiny parts. Large industrial printers can make parts several feet long. But bigger parts take more time. They also cost more.

Is it safe? Like any industrial process, safety matters. Handling fine metal powders needs care. Breathing them in isn’t good. Printing involves high heat and lasers. Proper ventilation and protective gear are essential. Operators follow strict safety rules.

(what is holding metal 3d printing back)

Will it replace traditional manufacturing? Not likely soon. It won’t replace casting or machining for everything. Think of it as another tool. It’s best for complex parts. It’s best for low volumes. It’s best for customization. It adds options. It doesn’t replace everything else.