Discover a professional 3D printing powder supplier

** Steel Magic: Just How 3D Printers Build Solid Items Layer by Layer **.

(what is metal 3d printing)

You recognize those plastic 3D printers? The ones that make little toys or phone situations? Imagine that, yet way harder. Believe jet engine components, custom medical implants, and even rocket nozzles. That’s metal 3D printing. It seems like sci-fi, however it’s actual production today. So, exactly how does it really function?

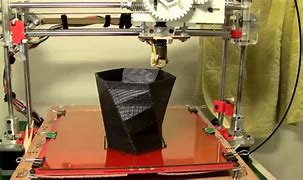

Fail to remember spraying thawed plastic. Steel printing is a different monster. It generally involves super fine steel powder, virtually like dust. Assume titanium, stainless steel, light weight aluminum, or even special alloys. A thin layer of this powder gets spread out across a build system. After that comes the magic part: a super-powered laser light beam or electron light beam zaps across the powder. This beam thaws the metal specifically where the style states it needs to be, fusing the tiny grains with each other. It happens extremely quick and at scorching temperature levels.

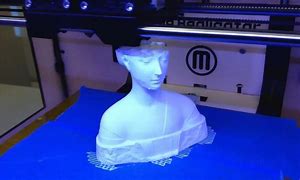

When that first layer is strong, the platform lowers just a little bit. A fresh layer of powder brushes up throughout the top. The laser discharges again, thawing the brand-new powder and also bonding it firmly to the layer below. This repeats. Layer after layer after layer. Gradually, specifically, a solid steel item rises from the powder bed. It’s like building a sandcastle, yet with lasers and steel, and way more accurate.

After printing, the whole point cools off inside the maker. The unused powder imitates assistance during printing. As soon as awesome, you raise out the block of powder with your new part buried inside. Workers meticulously clean away the loosened powder. This powder isn’t thrown away. They sieve it and use it once more for the next print. The part itself may need a bit more job. Sometimes there’s assistance product to eliminate, or the surface needs smoothing. It could go into a special oven for extra toughness. Yet the core shape? Developed totally by the printer.

Why trouble? Why not just machine a block of steel? Excellent inquiry. Steel 3D printing unlocks styles impossible with old approaches. Believe complex internal channels for cooling down inside a component. Think unbelievably lightweight frameworks with inner honeycombs, strong yet ventilated. Assume making simply one or two customized components fast, without pricey mold and mildews. It’s perfect for models, special clinical devices, or complex aerospace parts.

(what is metal 3d printing)

Factories utilize it. Hospitals use it. Automobile firms and rocket contractors use it. It’s making components lighter, more powerful, and sometimes cheaper. It allows designers think up wild new shapes and really develop them. The innovation maintains improving, faster, and able to take care of more metals. It’s not changing every factory tool, not yet. But it’s adding an effective new method to make things. The future of building complex steel parts is literally being published, one little layer at a time. That printer is probably whirring away today, making something outstanding.