Discover a professional 3D printing powder supplier

Title: Bigger is Better? The Truth About Industrial Metal 3D Printer Build Chambers

(what is the print bed size of a 3d printer industrial metal)

Main Product Keywords: Industrial Metal 3D Printer, Print Bed Size

1. What Exactly is “Print Bed Size” in Industrial Metal 3D Printing?

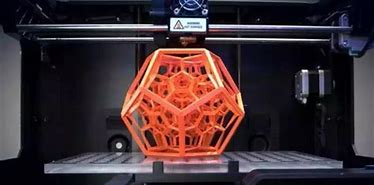

Forget the tiny hobbyist machines. Industrial metal 3D printing is serious business. The “print bed size” refers to the physical dimensions of the platform inside the machine where your metal part gets built, layer by layer. Think of it like the baking sheet inside an oven. This platform holds the raw material powder securely. The laser (or other energy source) then selectively melts this powder exactly where the digital design says to. The bed size defines the maximum length, width, and height (often called X, Y, and Z axes) of a single part you can produce in one go. It’s the machine’s build envelope. Manufacturers usually list it in millimeters or inches. Common sizes range from 250mm x 250mm x 300mm up to massive chambers exceeding 800mm x 400mm x 500mm. This size is a fundamental machine specification. It directly impacts what you can make. Knowing the bed size tells you the maximum physical boundaries of your printed object.

2. Why Does Print Bed Size Matter So Much for Metal Parts?

Size isn’t just about making big things. It impacts everything. Larger bed sizes allow you to print bigger components in one piece. This eliminates the need for welding or assembling smaller parts later. It saves time. It reduces potential weak points in the final product. Aerospace brackets or automotive chassis sections often need this scale. But even for smaller parts, bed size matters. A larger bed lets you pack more parts into a single build job. Imagine printing dozens of identical medical implants at once instead of just a few. This drastically improves production efficiency. It lowers the cost per part. You use the machine time better. Also, some complex part geometries might require specific orientations during printing. A larger bed offers more flexibility for positioning parts optimally. It gives you breathing room. Choosing a bed too small forces compromises. You might need to redesign parts. You might need more assembly steps. You might need more machine runs. All this adds cost and complexity. Getting the bed size right is crucial for efficient, cost-effective production.

3. How Do Manufacturers Determine and Use Print Bed Size?

Machine builders decide bed size based on engineering and market needs. They consider laser power, thermal management, recoater arm stability, and overall system cost. Bigger beds need more powerful lasers. They need stronger, more precise mechanics to move the laser or the bed. They need better temperature control across the entire powder bed. All this increases machine complexity and price. Once a machine is built, its bed size is fixed. You cannot easily change it. Operators use specialized software to prepare parts for printing. This software “nests” the 3D models virtually within the machine’s known build volume. The software checks that no part exceeds the X, Y, or Z limits. It arranges multiple parts efficiently. It ensures parts don’t overlap. It ensures supports (if needed) fit within the space. Operators must leave some clearance around the edges. The recoater blade needs space to move powder smoothly. Parts placed too close to the edge might have quality issues. The usable space is slightly smaller than the absolute maximum bed size. Understanding these limits is key for successful prints.

4. Applications: Where Bed Size Makes or Breaks the Part

The required bed size depends entirely on the job. Small, intricate parts dominate some industries. Dental labs printing crowns and bridges need precision. High resolution is critical. Large bed sizes are unnecessary. Machines like smaller DMLS/SLM systems are perfect here. Medical implants often fall into this category too. Conversely, the aerospace and defense sectors constantly push boundaries. They need large, complex, load-bearing components. Printing a large turbine blade housing or a satellite mounting bracket in one piece is a huge advantage. This demands large-format industrial metal printers. The automotive industry uses both ends. Prototyping complex engine parts might need a medium bed. High-volume production of smaller components uses smaller beds efficiently. The energy sector requires large valves, pump housings, and heat exchanger parts. These frequently need the biggest industrial machines available. Tool and die makers use metal 3D printing for conformal cooling channels inside molds. Larger molds require larger print beds. Choosing the right printer bed size is vital for meeting specific application demands. It directly affects design freedom and manufacturing feasibility.

5. FAQs: Industrial Metal Printer Build Size Demystified

Q1: Does a bigger print bed always mean a better printer?

Not necessarily. Bigger beds cost significantly more. They consume more power and powder. They require more maintenance. If you only make small parts, a large bed is inefficient and wasteful. Choose the bed size that matches your typical part sizes and production volume. A machine that fits your needs is better than the biggest one available.

Q2: Can I print parts larger than the bed size by assembling them?

Yes, but it’s complex. You can design large parts to be printed in sections. You then join them using techniques like welding, brazing, or mechanical fastening. This adds extra steps. It introduces potential failure points at the joints. It requires careful design for assembly. It increases cost and time. Printing in one piece is usually preferred for strength and integrity.

Q3: Is the advertised bed size the actual usable space?

Almost never. You must account for the “safe zone”. Leave space around the edges for the recoater mechanism. Leave space for potential part supports. The machine’s software usually defines the exact usable build volume. This volume is smaller than the physical platform dimensions. Always check the manufacturer’s specifications for the usable X, Y, Z dimensions.

Q4: How does bed size relate to precision?

Generally, larger beds can present challenges for maintaining absolute precision across the entire build area. Thermal gradients and mechanical deflections are harder to control over large distances. However, modern industrial machines use sophisticated calibration and compensation techniques. Reputable manufacturers ensure high precision even on large-format systems. Precision is a separate specification from bed size.

Q5: Are there standard bed sizes?

(what is the print bed size of a 3d printer industrial metal)

No universal standard exists. Different manufacturers offer various sizes. Common sizes cluster around certain dimensions (e.g., 250mm cubed, 400mm x 400mm x 400mm, 500mm x 500mm x 500mm, or larger rectangles like 800mm x 400mm x 500mm). The trend is towards larger sizes. New machines push the boundaries constantly. You must research specific models for their exact build volume.