Discover a professional 3D printing powder supplier

Metal Magic: What’s Cooking in Today’s 3D Printing Labs?

(what is used for metal 3d printing)

What Exactly Goes Into Metal 3D Printing?

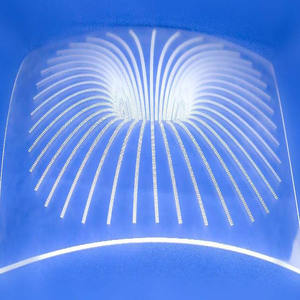

Metal 3D printing builds complex objects layer by layer. It uses metal powder. This powder is the essential raw material. Think of it like very fine metal sand. Different metals make different powders. Common choices include stainless steel, titanium, aluminum, and even special alloys like Inconel. The powder must be super clean. It must also flow easily. Particle size matters a lot. Tiny, uniform particles give the best results. Machines spread thin layers of this powder. Then a powerful heat source melts it precisely. This heat source fuses the powder into solid metal. The process repeats. Layer after layer builds the final part. So the main ingredients are specific metal powders and intense heat. The powder quality directly impacts the final part’s strength and finish.

Why Metal Printing is Changing the Game

Metal 3D printing offers big advantages. Traditional methods often waste material. Think machining a block of metal down to a shape. Chips fly everywhere. Metal printing uses only the powder needed for the part. This saves material and cost. Complex designs are possible. Imagine building a jet engine part with internal cooling channels. Machining this is hard or impossible. Printing builds it directly. Customization becomes easy. Making one unique part costs similar to making many identical ones. This is perfect for medical implants or custom tools. Speed matters too. Prototyping happens faster. Designers test ideas quickly. Production lead times shrink. Metal printing also enables lightweight designs. Strong, hollow structures reduce weight without losing strength. This is crucial for aerospace and racing. It unlocks new possibilities engineers only dreamed of before.

How These Machines Actually Build Metal Parts

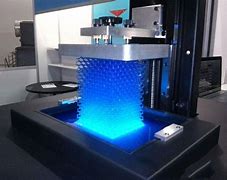

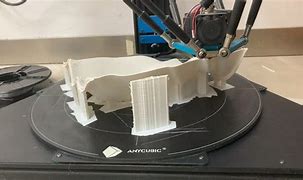

Several methods exist. The two most common are Powder Bed Fusion (PBF) and Directed Energy Deposition (DED). PBF machines work inside a chamber filled with inert gas. A recoater spreads a thin layer of metal powder over a build plate. A laser or electron beam scans the powder bed. It melts the powder exactly where the design specifies. The plate lowers slightly. Another powder layer spreads. The laser melts again, fusing to the layer below. This repeats until the part is complete. Unmelted powder supports the structure during printing. After printing, workers remove the part from the powder. They clean it and often heat-treat it for strength. DED is different. It feeds metal powder or wire through a nozzle. A laser or electron beam melts the material as it deposits onto a surface. DED builds parts larger than PBF. It is also great for adding features to existing parts or repairing worn components. Both methods require careful control of temperature and atmosphere.

Real-World Metal Printing Power Players

Metal 3D printing isn’t just for labs anymore. It’s making real things. Aerospace loves it. Companies print lightweight, strong brackets, fuel nozzles, and turbine blades. These parts fly on planes and rockets. The medical field uses it too. Surgeons implant custom titanium hip joints and spinal cages. These fit patients perfectly. Dental labs print crowns and bridges fast. The automotive industry benefits. Prototypes appear quicker. Custom racing parts improve performance. Even production cars use printed components. Toolmakers get stronger, conformal-cooled molds. These cool plastic parts faster in injection molding. Energy companies print complex parts for turbines and drilling equipment. Jewelers create intricate designs impossible by hand. Artists sculpt unique metal pieces. The applications keep growing as the technology improves and costs come down.

Your Top Metal Printing Questions Answered

1. Is it strong? Yes. Properly printed and heat-treated metal parts match or exceed the strength of traditionally made parts. The material properties are excellent.

2. How smooth is the surface? Directly printed parts often have a slightly rough surface. Think fine sandpaper. Post-processing like machining or polishing creates a smooth finish if needed.

3. Is it expensive? It can be. Machines and materials cost more than plastic printing. However, for complex parts, low volumes, or custom items, it often saves money overall by reducing waste and assembly steps. Costs are dropping steadily.

4. What about size limits? Printers come in different sizes. Desktop metal printers are small. Industrial machines can print parts meters long. DED can build very large structures.

5. Is it safe? Handling fine metal powders requires caution. Good ventilation and proper protective gear are essential to avoid inhalation. The printing process itself is enclosed and controlled. Operators need training.

6. How long does it take? Speed varies. Small, simple parts might print in hours. Large, dense parts can take days. It’s usually faster than traditional methods for complex shapes, especially prototypes.

7. Can I print anything? Almost. Design freedom is huge. But overhanging structures need support during printing. Very thin walls might be tricky. Designers learn specific rules for optimal printing.

8. What metals can I use? Many! Stainless steel (316L, 17-4 PH), Titanium (Ti-6Al-4V), Aluminum (AlSi10Mg), Cobalt Chrome, Nickel Alloys (Inconel 625, 718), Tool Steels, Copper, and precious metals like Gold and Silver are all printable.

9. What happens to unused powder? It’s recycled. Unmelted powder is collected, sieved, and blended with fresh powder for the next print. This minimizes waste.

(what is used for metal 3d printing)

10. Is it ready to use right off the printer? Usually not. Parts often need support removal, cleaning (like sandblasting), and heat treatment. Machining or surface finishing might also be needed.