Discover a professional 3D printing powder supplier

Metal Satisfies Plastic: The Surprising Fact About 3D Printed Firearms .

(what part of 3d printed guns are metal)

The globe of 3D printing constantly pushes boundaries. Individuals print whatever from playthings to homes. One questionable application grabs headings: 3D published weapons. Pictures typically show smooth, totally plastic weapons. This photo triggers a huge question. If the gun is printed, what parts in fact require actual metal? The response is extra complex than it appears. Understanding this mix of plastic and steel is crucial to realizing just how these tools feature, their restrictions, and the genuine obstacles they provide. Let’s pull back the drape.

Main Item Keywords: 3D Printed Guns, Metal.

1. What Metal Parts Conceal Inside a “Plastic” Weapon? .

Calling something a “3D printed gun” is a little bit deceptive. Think of it like a set. The plastic structure or receiver is generally the part printed on a standard 3D printer. This plastic covering imitates the skeletal system. It holds everything with each other. Nonetheless, critical components inside this covering definitely must be steel. These are the components managing severe pressure and warmth. The barrel is one of the most vital metal piece. Firing a bullet develops enormous stress and heat. Plastic just thaws or shatters under these conditions. Steel barrels include this pressure securely. Next is the shooting pin. This tiny, solidified steel rod strikes the guide on the cartridge. It needs to be tough and accurate. Springs are vital as well. They power the firing device and assistance cycle the action. Springs need flexibility and toughness only metal supplies accurately. Bolts or breech blocks, depending on the style, likewise face high tension. They need to be steel to endure duplicated effects. So, while the outer body could be plastic, the guts requiring toughness and durability are usually traditional metal components.

2. Why Can Not We Just Publish the Whole Gun in Plastic? .

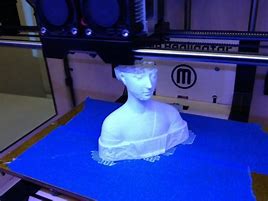

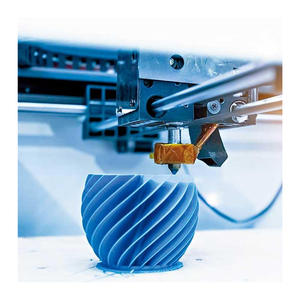

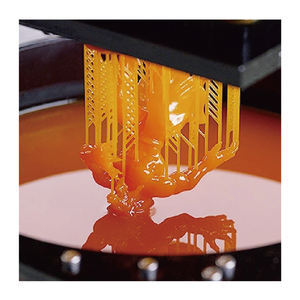

It comes down to physics. Present consumer-grade 3D printers mostly use plastics like PLA or ABS. These materials are excellent for many points. They are not fantastic for consisting of explosions. When a bullet fires, gunpowder ignites swiftly. This produces a mini-explosion inside the chamber. Stress escalate. Temperature levels struck hundreds of degrees instantaneously. Common 3D published plastics melt means too conveniently. They additionally lack the large tensile toughness. A plastic barrel would likely burst when discharged. This is extremely dangerous for the shooter. The firing pin demands identify solidity to accurately fire up the guide. Plastic is also soft and would deform quickly. Springs call for specific metallurgical residential or commercial properties. Plastic springs don’t have the essential breeze and durability. High-performance industrial printers can use metal powders. These devices are extremely pricey. They are complex to operate. They are far beyond the reach of most hobbyists. So, in the meantime, absolutely useful guns need incorporating published plastic parts with crucial, off-the-shelf metal components. Plastic alone isn’t sufficient.

3. Just how Do Plastic and Steel Combine in a Printed Weapon? .

Building a practical device entails setting up. It’s rarely as simple as striking ‘print’ and obtaining a ready-to-shoot weapon. Here’s the typical procedure. Initially, someone downloads or makes the electronic declare the plastic parts. These are usually the reduced receiver or structure. This component holds the trigger group and magazine. The upper receiver may additionally be published on some styles. This component houses the barrel. Next off, the building contractor acquires the essential metal components independently. These are typical weapon parts. They are often uncontrolled pieces like metal tubes for barrels, or components kits. Sometimes people get these components online. In some cases they salvage them from existing guns. In some cases they device easy components themselves. The published plastic components imitate a custom real estate. The building contractor assembles the steel components– barrel, screw, shooting pin, springs– into this plastic framework. This assembly calls for tools and some mechanical knowledge. It entails boring openings, fitting pins, and guaranteeing whatever lines up appropriately. The final device is a crossbreed. It’s a marriage of modern published plastic and typical, vital steel pieces. The plastic supplies the custom-made type. The metal gives the vital feature and safety.

4. What Are the Actual Applications and Limits of These Crossbreed Guns? .

The existence of these weapons sparks extreme debate. Comprehending their actual use and limitations is necessary. Some building contractors are hobbyists. They are attracted by the technological challenge. They delight in the process of production and assembly. Others see them as tools for political protest. They focus on principles like decentralized manufacturing. Problems regarding possible criminal use are substantial. Police globally track this concern. However, the useful reality usually varies from the hype. Reliability is a significant obstacle. Plastic frames can fracture under recoil stress. Layer bond in prints can fall short. Poor setting up causes breakdowns. Accuracy is often inadequate compared to commercial firearms. Safety is a big problem. A severely made plastic frame or a badly fitted barrel can stop working catastrophically. This injures the shooter. Ammunition is still required. It isn’t published. The metal components themselves frequently need controlled purchases or considerable machining ability. While functional crossbreed guns exist, they are generally much less dependable, much less exact, and possibly a lot more hazardous than conventional firearms. They stand for a specific niche ability, not a widespread replacement.

5. FAQs: Your Top Concerns Answered .

Individuals have many inquiries about this subject. Below are some common ones:.

Can you actually print a gun that terminates? Yes, however it’s practically never ever completely printed. A useful firearm calls for key metal components like the barrel and firing pin. The plastic components hold these with each other.

Are these weapons legal? Rules differ dramatically by nation and even within nations (like different US states). In numerous areas, producing any gun without a license is illegal. Possessing particular published parts, particularly frames/receivers, is commonly regulated like a conventional firearm. Lawful suggestions certain to your place is essential. Never ever think it’s legal.

Why not just prohibit the data? Prohibiting electronic data is unbelievably hard. Data spread quickly online with peer-to-peer networks and encrypted channels. Removing them from one system simply pushes them somewhere else. Enforcement is a significant obstacle.

Do they turn up on metal detectors? Possibly, however not dependably. While they consist of steel components (barrel, shooting pin), these components are small. A well-crafted hybrid weapon could have less steel than a standard gun. It might potentially evade detection in some situations, though this is not assured.

(what part of 3d printed guns are metal)

Are they like genuine guns? Normally, no. Crossbreed printed guns are normally much less trusted. They are much less long lasting. Accuracy is typically even worse. Safety and security risks are higher due to prospective product failure or poor setting up. They are not equivalent to commercially manufactured guns in performance or security.