Discover a professional 3D printing powder supplier

The Metal Heart of Plastic Pistols: What Makes Hybrid Guns Tick?

(what part of hybrid 3d printed guns are metal)

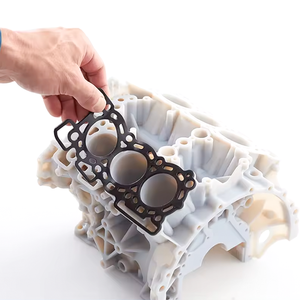

You hear about 3D printed guns. Pictures pop up online. Sleek plastic shapes looking like something from a sci-fi movie. But hold on. Can plastic really handle the brutal forces inside a gun? The answer is mostly no. That’s why “hybrid” guns exist. They mix 3D printed plastic parts with good old-fashioned metal. It’s a blend of new tech and old reliability. So, what bits absolutely need to be metal? Let’s look inside.

Think about firing a bullet. Gunpowder ignites. It creates a mini explosion. This explosion pushes the bullet down the barrel incredibly fast. The pressures are huge. Temperatures skyrocket. Plastic just isn’t tough enough for this job. It melts. It cracks. It fails spectacularly. This is why the barrel itself is almost always metal. It channels that explosive force safely. A plastic barrel? It’s a pipe bomb waiting to happen. Metal handles the heat and pressure without flinching.

Next up is the chamber. This is where the cartridge sits before firing. The explosion happens right here. It needs to contain that blast perfectly. If the chamber fails, the gun blows up in your hand. Plastic chambers are dangerous. They can’t seal the hot gases reliably. Metal chambers are the only safe option. They keep the explosion pointed down the barrel, not back at you.

Then there’s the bolt or breech face. After firing, this part slams back. It absorbs massive recoil. It also has to hit the next cartridge hard to chamber it. Plastic parts here wear out fast. They shatter. They deform. Metal bolts handle the repeated pounding. They last longer. They keep the gun cycling reliably. Imagine a plastic hammer hitting metal over and over. It breaks quickly. The bolt faces the same punishment.

Don’t forget the firing pin. This tiny part strikes the primer on the cartridge. It needs a very hard, precise hit. Plastic firing pins bend. They snap. They misfire. A metal firing pin is essential. It delivers the sharp, consistent blow needed to ignite the primer. Without it, the gun simply won’t shoot.

Springs are another must-have metal part. They power the gun’s action. They push the bolt forward. They return the trigger. Plastic springs lack the strength and elasticity. They lose tension fast. Metal springs provide the necessary snap and durability. They make the gun work smoothly every time.

Sometimes small pins and bushings are metal too. These parts take friction. They guide moving components. Plastic wears down quickly under constant rubbing. Metal pins hold up much better. They keep things aligned. They reduce wear on other parts.

(what part of hybrid 3d printed guns are metal)

So, the plastic parts? They form the frame, the grip, the magazine body, maybe some external covers. These parts handle less stress. They shape the gun. They make it lighter. They allow for custom designs easily printed at home. But they rely entirely on the hidden metal skeleton. The metal parts handle the violence. They manage the fire and force. They make the gun function safely. They make it last more than a few shots. This metal core is non-negotiable. It’s the hidden strength inside the plastic shell. Without these chunks of steel, you just have a fragile model, not a working weapon. The plastic might shape the gun, but the metal makes it work.