Discover a professional 3D printing powder supplier

** Metal 3D Printing: How Much Can We Truly Make? **.

(what percent of metal parts can be 3d printed)

People ask, “What percent of steel components can be 3D printed?” It’s not about percents. It’s about possibilities. Requesting a portion misreads. 3D printing steel isn’t magic. It can’t make everything. It beams for certain tasks. Consider what makes a component difficult for old methods. That’s frequently where 3D printing victories.

Initially, size issues. Huge metal parts are tough. Think engine blocks or substantial equipment real estates. Many steel printers today have restrictions. Their build chambers are boxes, maybe a meter cubed. Some larger makers exist. They are pricey. They are rare. Making big components needs massive printers. That’s not practical yet. So, large components? Mainly not printable today.

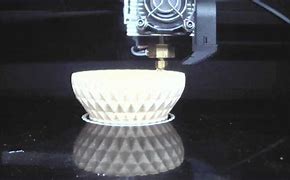

Next off, intricacy is crucial. This is where 3D printing shines. Fail to remember percents. Think shapes. Can you also * make * the component another way? Typical machining cuts away metal. It struggles with hollow areas inside. It dislikes twisting channels. Casting requirements molds. Complex shapes make mold and mildews impossible or insane pricey. 3D printing constructs layer by layer. Internal latticeworks? No worry. Facility air conditioning paths inside a generator blade? Perfect. Bio-mimetic structures? Yes. If the style is wild, 3D printing could be the only means. Or the least expensive method. So, intricacy presses parts in the direction of printing.

Product selection is massive also. Not all steels play great with printers. The usual ones function well: titanium alloys, stainless-steels, nickel superalloys, some aluminum, cobalt chrome. These melt predictably. They strengthen well under the laser or electron beam. Some steels are nightmares. High-strength aluminum typically splits. Pure copper shows excessive laser light. It’s hard to thaw continually. Particular tool steels warp severely. Responsive metals like magnesium? Fire danger. Specialized alloys often need custom printing recipes. That takes some time and money. So, the metal itself decides if printing is also feasible.

Expense is always an element. 3D metal printing isn’t cheap. The makers set you back a lot. The steel powder costs more than solid bars. Printing is sluggish. Post-processing takes some time. Support frameworks need removing. Components frequently require warm treating. They require surface area ending up. For a simple brace? Machining is quicker. It’s less costly. For an intricate aerospace brace conserving weight? The printing price might be worth it. The break-even point depends. It depends upon complexity, product, and the amount of you require. Low volume, complicated parts? Printing commonly wins. High volume, straightforward components? Traditional techniques win.

One more thing: strength isn’t constantly the exact same. Printed metal parts can be solid. In some cases extremely solid. However the toughness might depend upon direction. Consider wood grain. Printed metal has a grain too. Evaluating verifies the component meets specifications. However it’s not constantly similar to a built item. Vital load-bearing parts need cautious design. They require mindful printing. They need testing. This isn’t a deal-breaker. It simply needs interest.

(what percent of metal parts can be 3d printed)

So, fail to remember the percent video game. It’s the incorrect question. The genuine question is: Does your * certain * metal component gain from 3D printing? Look at its size. Is it also large for present printers? Look at its shape. Is it exceptionally facility? Does standard manufacturing choke on it? Check the product. Does it publish well? Ultimately, problem the numbers. Does the value of the complex layout surpass the printing cost? The modern technology is impressive. It opens up doors we could not open in the past. It lightens rockets. It makes far better medical implants. It makes cooler warm exchangers. But it does not replace the lathe or the forge for everything. The “percent” isn’t fixed. It grows as printers grow. It expands as materials improve. It expands as expenses come down. Today, concentrate on where it fixes troubles nothing else can. That’s where the actual magic occurs. That’s where the future is being constructed, layer by little layer.