Discover a professional 3D printing powder supplier

Title: Metal Magic: What Headaches Does 3D Printing Really Fix?

(what “problem” does 3d “metal” printing “solves”)

Main Product Keywords: 3D Metal Printing

Imagine a master craftsman, able to shape solid metal into wildly complex forms – forms that would make a traditional machinist sweat or simply say “impossible.” That’s the promise whispering from the world of 3D metal printing. It’s not just about making cool trinkets. This tech is solving real, stubborn problems that have plagued designers and manufacturers for decades. Let’s dive into the metal dust and see what headaches it’s actually curing.

1. What is 3D Metal Printing Anyway?

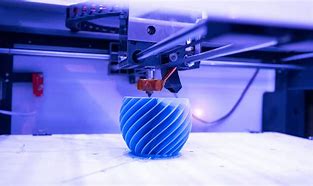

Forget plastic hobby printers. 3D metal printing, often called metal additive manufacturing (AM), is a whole different beast. Think of it as building an object layer by tiny layer, but using metal instead of ink or plastic. A high-powered laser or electron beam precisely melts fine metal powder, fusing it together exactly where the digital design says it should. It’s like welding, but controlled by a computer with incredible precision, building up the part slice by slice from nothing. The materials? Everything from common stainless steel and titanium to exotic superalloys used in jet engines. It takes digital blueprints and turns them directly into solid, functional metal parts. No massive blocks of metal needing cutting away. No complex molds needing creation first. Just pure, digital-to-metal magic.

2. Why Were These Problems Such a Nightmare Before?

Traditional metalworking methods are fantastic, but they hit walls. Big, expensive walls. Think about complex shapes. Machining a twisted internal channel inside a solid block? Often impossible. Casting needs a mold, which itself can be complex and costly, especially for just one or a few parts. Forging requires enormous forces and is limited in geometry. These methods subtract material or force it into shape. They struggle with intricate details, hollow structures, or parts that curve and twist in unusual ways. Also, making custom parts or small batches was painfully expensive. You needed special tooling, molds, or fixtures each time, driving costs sky-high. Needing a unique replacement part for an old machine? Good luck without paying a fortune or waiting months. Plus, the sheer waste! Machining often cuts away more than 70% of a solid metal block. That’s costly material literally turned into scrap. These limitations stifled design, slowed innovation, and made customization a luxury.

3. How Does 3D Metal Printing Solve These Issues?

This is where 3D metal printing flips the script. Its superpower is design freedom. Since it builds layer by layer, complexity is essentially free. Those impossible internal channels? Printed hollow. Intricate lattice structures for lightweight strength? Done. Organic, flowing shapes mimicking nature? No problem. The printer doesn’t care how complex the design is; it just follows the digital instructions. This tackles the “impossible geometry” headache head-on. Then there’s the tool-less aspect. Need one part or a hundred? The process is largely the same. No need for expensive molds, dies, or specialized fixtures for each new design. This slashes the cost and time for prototypes, custom parts, and low-volume production – solving the “small batch/customization nightmare.” Finally, it’s inherently less wasteful. You only use the metal powder that actually becomes part of the final object. While some unused powder needs recycling, it’s dramatically less waste than machining a block. This tackles the “material waste mountain.” It builds what you need, almost exactly where you need it.

4. Where is 3D Metal Printing Making Waves? (Applications)

You’ll find this tech transforming demanding industries:

Aerospace & Rockets: Making ultra-strong, incredibly lightweight components. Think fuel nozzles with intricate internal cooling channels impossible to machine, or turbine blades optimized for performance. Less weight means more fuel efficiency or bigger payloads.

Medical Implants: Crafting personalized hip replacements, spinal cages, or cranial plates perfectly shaped to fit an individual patient’s unique anatomy. Porous surfaces can even encourage bone growth. This is custom healthcare at a metal level.

High-Performance Automotive & Racing: Creating lighter, stronger parts for engines, transmissions, and chassis. Rapid prototyping lets teams test and iterate designs incredibly fast. Custom cooling solutions for electric motors are a big area.

Energy (Oil/Gas, Turbines): Producing durable parts that withstand extreme heat and pressure, like turbine components or specialized valves, often with improved internal flow paths. Faster production of hard-to-source replacement parts keeps operations running.

Tooling & Manufacturing: Printing conformal cooling channels directly into molds and dies. These channels follow the mold’s shape, cooling it faster and more evenly, leading to shorter production cycles and higher quality plastic parts.

Rapid Prototyping: Getting functional metal prototypes in days, not weeks or months, accelerating product development cycles dramatically.

5. 3D Metal Printing FAQs: Your Burning Questions

Is it really strong? Yes! Properly printed metal parts can be as strong, sometimes even stronger, than traditionally made parts. The key is using the right process, material, and settings, and often applying post-processing like heat treatment.

Isn’t it super slow? It’s slower than stamping out parts by the thousands, definitely. But for complex parts, prototypes, or low volumes, it’s often faster overall because it skips the lengthy tooling and setup steps. Speed is improving constantly.

What about cost? Is it cheap? The machines and metal powder are expensive. For simple parts made in high volumes, traditional methods are usually cheaper. But for complex parts, custom items, or low volumes, 3D printing often wins on total cost by eliminating tooling and reducing waste. The value is in complexity and agility.

Can it make big parts? Absolutely. Industrial printers are getting larger, capable of producing parts meters in size. Printing large parts often involves joining smaller sections or using very large machines.

Is the surface finish good? Straight off the printer, the surface can be rough. Most parts need finishing like machining, polishing, or sandblasting to achieve a smooth surface. However, the technology for better “as-printed” surfaces is advancing.

(what “problem” does 3d “metal” printing “solves”)

Will it replace all traditional manufacturing? Unlikely soon. It’s another powerful tool in the toolbox. Think of it as ideal for complex, customized, or low-volume metal parts where its unique advantages shine. Traditional methods still rule for high-volume, simple shapes. They work together.