Discover a professional 3D printing powder supplier

Title: Steel Magic: Unlocking Uncomplicated 3D Printing (Tip: It’s Surprisingly Typical!) .

(what type of metal is easiest to 3d print)

1: What Makes a Metal “Easy” to Publish? .

Not all metals play wonderful with 3D printers. Finding the easiest metal means seeking specific characteristics. High melting factors often cause problem. Steels needing extreme warmth warp more quickly. Buckling ruins prints. Some metals react severely with oxygen throughout printing. This develops weak spots. Metals that reduce a great deal when cooling down fracture. Fractures suggest failed components. Great flow is important. The metal powder have to melt smoothly. It needs to fuse perfectly layer by layer. Printers handle some metals better. The technology matters. Metal powder bed blend is common. It utilizes lasers or electron light beams. Simpler makers take care of simpler metals much better. So, the most convenient steels melt at reduced temperatures. They resist bending and cracking well. They flow regularly. They work dependably with basic tools. They don’t require unique gases or extreme setups. Stainless-steel, particularly 316L, beams right here.

2: Why Stainless-steel 316L Policy the “Easy” Group .

Stainless-steel 316L is the champion for easily accessible metal 3D printing. Its secret depend on balance. It thaws at a workable temperature. This is vital. Reduced warmth means less anxiety on the device. Less heat suggests less bending pressure. The “L” means reduced carbon. Low carbon is vital. It significantly minimizes the danger of breaking after printing. 316L streams well in its powdered kind. It thaws uniformly under the laser or electron beam of light. This creates solid, thick layers. It manages oxygen direct exposure sensibly well. Many printers use inert gas like argon. This safeguards 316L effectively. The powder is easily available. It costs much less than lots of unique metals. The majority of industrial steel printers take care of 316L conveniently. Print settings are well-documented. This makes it predictable. Success prices are high. You get solid, corrosion-resistant parts accurately. It’s the excellent starting point.

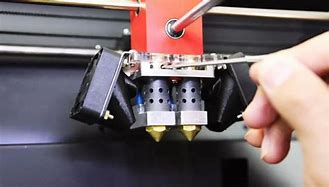

3: How Printing “Easy” Metals Like 316L Really Functions .

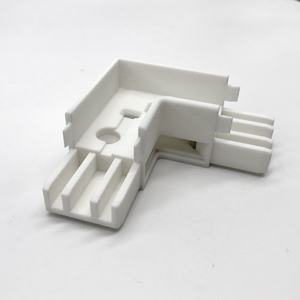

The main procedure for very easy steels like 316L is Powder Bed Blend (PBF). Think about it like laser sintering or melting. A thin layer of metal powder spreads across a build platform. A powerful laser or electron light beam scans the powder. It complies with the part’s digital cross-section. The beam thaws the powder fragments specifically. They fuse together and solidify quickly. The system reduces a little. One more layer of powder spreads. The light beam melts this brand-new layer. It likewise bonds it to the layer listed below. This repeats hundreds of times. Layer by layer, the solid steel part grows inside the powder bed. After printing, the part cools down inside the equipment. The entire powder cake is removed. The extra powder obtains brushed or blown away. The printed part often needs assistance frameworks. These supports hold overhangs during printing. Removing supports is a post-processing step. Heat therapy could adhere to. This alleviates interior stresses. It improves the steel’s last properties. The process is intricate but structured for steels like 316L.

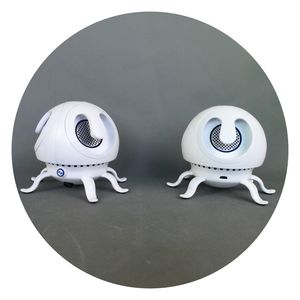

4: Applications Where Easy Printing Metals Beam .

The convenience of printing 316L opens several doors. It’s not nearly simpleness; it’s about useful, strong parts. Custom-made clinical implants benefit substantially. Surgical guides, bone plates, and dental parts require biocompatibility and strength. 316L supplies this reliably. Complex liquid systems require intricate networks. Shutoffs, manifolds, and pump components published in 316L handle pressure and deterioration. The aerospace sector uses it for brackets, housings, and engine elements. Lightweight yet solid designs are possible. Automotive prototyping increases with printed jigs, components, and personalized tooling. Functional prototypes in 316L examination like last steel parts. Consumer goods see durable, intricate layouts. Enjoy instances, custom fixtures, and one-of-a-kind precious jewelry take advantage of its gloss and toughness. Fixing high-value metal parts becomes feasible. Printing a replacement gear or brace straight onto existing machinery conserves time and expense. Anywhere durable, corrosion-resistant metal components are required, especially intricate ones, 316L printing uses a fast track.

5: Frequently asked questions About Publishing the Easiest Metals .

(what type of metal is easiest to 3d print)

Individuals commonly ask similar questions about simple metal printing. Can I publish steel in your home? Not really. Industrial steel printers are huge, costly, and need special handling. They are not desktop equipments. Is published 316L as solid as conventional steel? Yes, when published and refined properly, it meets or surpasses basic 316L residential or commercial properties. It’s actual metal. Why not just make use of aluminum? Light weight aluminum can be printed, however it’s more difficult. It mirrors laser light much more, thaws at a lower temperature level calling for cautious control, and is more susceptible to hot breaking. 316L is typically much more forgiving. Exactly how costly is it? The printers cost a whole lot. The powder is less costly than titanium but greater than plastic. The value remains in complex, lightweight styles difficult to maker otherwise. What regarding surface area finish? As-printed components have a harsh, grainy surface. They require machining or brightening for a smooth finish. Post-processing adds cost. Is it secure? Managing great steel powders calls for care. Appropriate air flow and protective gear are vital to prevent breathing or fire risks. Safety and security procedures are rigorous.