Discover a professional 3D printing powder supplier

** What Kinds of Steel Can You Actually 3D Print? **.

(what types of metal can be 3d printed?)

Imagine holding a complex metal part in your hand. It’s light-weight, solid, and made intact. No welding, no screws. Just how? 3D printing. However not all metals play good with printers. Allow’s break down the steels that do– and why they’re changing industries from aerospace to jewelry.

** Stainless Steel **.

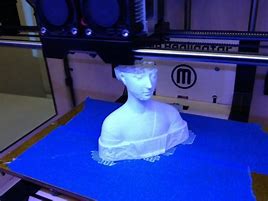

Stainless steel is the workhorse of steel 3D printing. It is difficult, resists rust, and takes care of warm well. Printers melt stainless steel powder layer by layer to develop parts like devices, pipes, or even decorative things. Auto business utilize it for custom braces. Health centers utilize it for surgical devices. The most effective component? It’s more affordable than many fancy steels, so it’s a best for daily jobs.

** Titanium **.

Titanium is the super star. It’s lighter than steel but equally as solid. Aerospace and clinical fields enjoy it. Believe jet engine components or hip implants. Printing titanium isn’t very easy, though. It needs lasers so powerful they thaw the powder at over 1,600 ° C. The outcome? Components that survive extreme problems. Bonus offer: Titanium’s all-natural appearance makes it prominent for premium precious jewelry and watches.

** Light weight aluminum **.

Light weight aluminum resembles the pleasant neighbor of metals. It’s light, cheap, and prints smoothly. Ever seen a bike structure or drone part made with 3D printing? Possibilities are it’s aluminum. The metal’s mix of toughness and agility makes it ideal for anything that needs to scoot without damaging. Plus, it’s recyclable– so green designers like it.

** Nickel Alloys **.

Nickel alloys like Inconel are the tough guys. They make fun of warmth, corrosion, and pressure. Gas wind turbines, rocket engines, and nuclear reactors count on them. Printing these alloys is tricky. They require precise temperature level control. Once printed, they’re unstoppable. Ever before become aware of a steel that gets more powerful when heated up? Inconel does that.

** Cobalt-Chrome **.

Cobalt-chrome is the medical wonder. It’s biocompatible, suggesting your body will not reject it. Dental practitioners use it for crowns. Doctors utilize it for joint replacements. The metal’s also common in high-stress components like wind turbine blades. It’s expensive, however worth it for work where failure isn’t a choice.

** Copper **.

Copper’s specialty? Performing warmth and electrical energy. 3D-printed copper components are appearing in electronic devices and cooling systems. Image an integrated circuit with a personalized copper heatsink. Or a car’s electrical motor with printed coils. The catch? Copper mirrors laser light, so printing it needs unique setups.

** Gold and Silver **.

Yes, you can 3D print bling. Jewelers utilize printers to make intricate rings, pendants, and chains. Traditional methods waste material. Printing makes use of just what’s required. Gold and silver powders are merged thorough shapes impossible with molds. It’s not simply for appearances– tailor-made dental crowns utilize printed gold as well.

** Tool Steel **.

Tool steel is for durable jobs. Drills, molds, cutting gear. It’s hard, wear-resistant, and manages repeated anxiety. Printing it allows suppliers produce tools with inner air conditioning networks. That means longer-lasting drills or mold and mildews that cool down much faster.

** The Large Photo **.

(what types of metal can be 3d printed?)

3D printing metals isn’t magic. It’s scientific research. Each steel has its quirks. Some require insane heat. Others fight lasers. Yet when done right, the outcomes reshape how we develop things. From small jewelry to large jet parts, the opportunities maintain expanding. New steels sign up with the checklist each year. That recognizes? Maybe at some point we’ll publish things we can not also imagine today.