Discover a professional 3D printing powder supplier

** When Did 3D Metal Printing First Emerge? **.

(when did 3d metal printing come out)

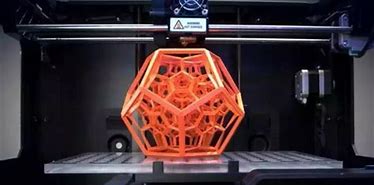

Image an equipment crafting elaborate steel parts layer by layer, like a modern blacksmith collaborating with lasers as opposed to hammers. This isn’t science fiction. It’s 3D metal printing. Yet when did this advanced technology step into the real world? Let’s rewind the clock.

The story starts in the 1980s. Back then, 3D printing was simply plastic. Early machines squirted melted plastic to construct toys, prototypes, and novelties. Metal was also tough to manage. Melting steel needed means much more warmth. Lasers got in the scene later.

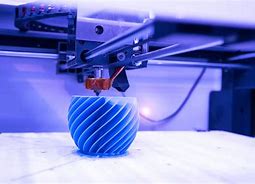

By the mid-1990s, designers split the code. A German company named EOS released among the initial metal 3D printers in 1994. It utilized a method called “selective laser sintering.” A laser beam zapped small steel particles, integrating them into solid shapes. The process was sluggish. The makers were massive. Just huge business like aerospace giants might manage them.

Progress didn’t stop. In the very early 2000s, a new technique called “direct steel laser sintering” (DMLS) turned up. This allowed printers produce denser, stronger steel components. All of a sudden, sectors took notification. Clinical companies printed customized implants. Vehicle manufacturers checked lightweight engine elements. Even NASA experimented with printing rocket parts.

The real development occurred 2010. Patents for laser-sintering tech ended. Smaller business jumped in. Prices dropped. A start-up can currently buy a steel printer for under $100,000. That’s still pricey, however method more affordable than the million-dollar devices of the ’90s.

Why does this issue? Conventional metalworking typically includes cutting, grinding, or molding resources. It’s wasteful. 3D printing includes material just where required. Less waste. Much less cost. Facility styles? Not a problem. Picture a metal brace with honeycomb withins– light-weight but solid. Difficult to make with old approaches. Easy for a 3D printer.

Take aerospace. GE Air travel printed gas nozzles for jet engines in 2015. Each nozzle was a single piece, replacing 20 welded components. It considered 25% much less. Gas effectiveness got better. That’s a big bargain when you’re melting hundreds of gallons per flight.

Medicine saw success also. Dental experts currently print crowns in hours, not weeks. Surgeons use 3D-printed titanium bones for substitutes. One person in the Netherlands got a custom-printed head implant. Fit flawlessly. Healing time? Cut in half.

Not every little thing’s smooth. Early metal printers were particular. A tiny error could spoil a component. Materials were restricted. You could not just toss any type of steel into the maker. The majority of printers made use of specific alloys like titanium or stainless steel.

Today’s devices are smarter. Sensors keep an eye on each layer. Software program fixes errors on the fly. New steels like copper and aluminum are signing up with the celebration. Print speeds are up. A part that took days in 2010 may take hours currently.

That’s utilizing this technology? Everybody. Automotive brands like BMW print cars and truck parts. Jewelers craft thorough metal pendants. Also the army builds custom-made gear for soldiers. Enthusiasts? They’re obtaining more detailed. Desktop computer steel printers are still rare, however labs and maker areas typically have one.

The trip isn’t over. Scientists are tinkering with multi-metal printing. Envision a single things mixing copper and steel– perfect for electronic devices or heat-resistant tools. Others are increasing rate. One business asserts it can publish a steel bike frame in a day.

(when did 3d metal printing come out)

From clunky prototypes to mission-critical jet components, 3D metal printing has actually come a long means. It’s reshaping manufacturing facilities, healthcare facilities, and labs. Next time you see a smooth metal gadget, there’s an opportunity it started as an electronic data and a laser light beam.