Discover a professional 3D printing powder supplier

Title: The Metallic Revolution: When Did 3D Printing First Fuse With Metal?

(when did metal start to get 3d printed)

Main Product Keywords: 3D Printed Metal

1. What Exactly is 3D Printed Metal?

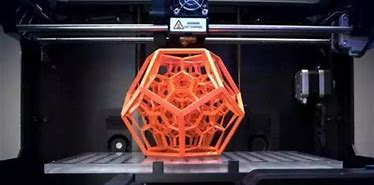

Forget plastic trinkets. 3D printed metal means creating solid, functional metal parts directly from a digital design. Think of it like a super-precise robotic welder building an object layer by layer. Instead of carving away material from a block, it adds material only where needed. This process uses fine metal powder, often titanium, stainless steel, aluminum, or even exotic alloys. A powerful heat source, usually a laser or electron beam, selectively melts the powder. It fuses tiny particles together, one thin slice at a time. The result is a fully dense metal component. This component emerges directly from the printer bed. It often needs some finishing work. But its core shape and structure are formed in one go. This technology breaks free from traditional manufacturing limits. It enables incredibly complex shapes impossible with machining or casting. Internal channels, intricate lattices, and organic forms become achievable. This is additive manufacturing for metal. It represents a fundamental shift in how we make strong, durable things.

2. Why Bother Printing Metal Parts?

Traditional metal manufacturing works well for simple, mass-produced items. But it struggles with complexity and customization. That’s where metal 3D printing shines. Its biggest draw is design freedom. Engineers can dream up parts with internal cooling channels snaking through them. They can create lightweight honeycomb structures inside solid components. They can make shapes mimicking nature itself. These designs boost performance. They reduce weight. They improve efficiency. Think lighter aircraft parts saving fuel or complex medical implants perfectly matching a patient’s bone. Another major advantage is waste reduction. Machining often cuts away over 90% of a metal block. Printing uses only the material needed for the part itself. This saves costly metal. It makes production more sustainable. Speed is crucial too. Printing a complex metal prototype might take days. Creating the same part traditionally could take months. This accelerates innovation and product development cycles. Printing also excels at low-volume production. Making custom or replacement parts becomes economically viable. You don’t need expensive molds or tooling. This is a game-changer for niche industries and legacy equipment support.

3. How Does Metal Actually Get Printed?

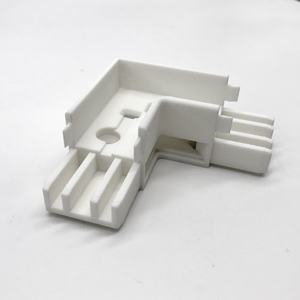

Several methods exist. The two most common are Powder Bed Fusion techniques. Selective Laser Melting (SLM) and Direct Metal Laser Sintering (DMLS) dominate. Here’s the basic process. First, a thin layer of fine metal powder spreads across a build platform. Next, a high-power laser scans the powder surface. It follows the cross-section of the part defined by the digital file. The laser melts the powder particles. They fuse together and to the layer below. The build platform lowers slightly. Another layer of powder spreads across the top. The laser then melts the next cross-section. This cycle repeats. Layer after layer builds the part inside a chamber filled with inert gas. This gas prevents oxidation of the hot metal. Electron Beam Melting (EBM) uses a similar powder bed approach. But it employs an electron beam in a high vacuum instead of a laser. Another method is Directed Energy Deposition (DED). Here, metal powder or wire feeds into a focused heat source. This source melts the material as it deposits it onto a surface. DED is great for adding features to existing parts or large-scale repairs. After printing, parts are usually encased in unused powder. They require careful removal. Post-processing like heat treatment, support structure removal, and surface finishing is almost always necessary. This ensures the final part meets strength and quality standards.

4. Where is 3D Printed Metal Making Waves?

The applications are exploding. Aerospace loves it. Companies print complex fuel nozzles, lightweight structural brackets, and heat-resistant turbine blades. These parts perform better. They make planes lighter and more efficient. Weight savings translate directly to fuel savings. The medical field embraces it too. Surgeons use patient-specific implants for knees, hips, and skulls. These implants fit perfectly. They promote faster healing. Dental labs print crowns and bridges with incredible accuracy. The automotive industry uses it for high-performance racing components. They create custom engine parts and lightweight structures. Tooling benefits immensely. Manufacturers print conformal cooling channels directly inside molds. This cools plastic parts faster. It speeds up production cycles significantly. Energy sectors adopt it for complex heat exchangers and turbine components. It handles extreme environments. Even jewelry designers use precious metal printing. They create intricate pieces impossible by hand. The defense sector prints specialized components for vehicles and equipment. Customization and rapid repair are key advantages. The potential keeps growing as materials and machines improve. This technology reshapes entire industries.

5. FAQs: Your Metal 3D Printing Questions Answered

People have many questions about this technology. Here are clear answers to some common ones.

1. How strong are 3D printed metal parts? Properly printed and processed parts can be just as strong as traditionally made metal parts. They meet demanding industry standards for aerospace and medical use. The material properties are excellent.

2. Is it really cost-effective? It depends. For simple, mass-produced items, traditional methods are cheaper. For complex, custom, or low-volume parts, printing often wins. It eliminates expensive tooling. It reduces material waste significantly. The total cost equation is changing.

3. What metals can be printed? Many! Common ones include stainless steels, titanium alloys, aluminum alloys, nickel superalloys, cobalt-chrome, and tool steels. Research constantly expands the list. Gold and silver are printable too for specialized applications.

4. How long does printing take? Speed varies widely. A small part might take hours. A large, complex part could take several days. Factors include part size, complexity, chosen technology, and layer thickness. It’s generally slower than mass production but faster for complex one-offs.

5. Can I print large objects? Yes, but size is limited by the printer’s build chamber. Industrial machines can print parts meters in size. For very large structures, techniques like Directed Energy Deposition (DED) are used. They build features directly onto existing components.

6. Is surface finish good? Printed surfaces have a characteristic texture. They often look grainy or slightly rough straight off the printer. Post-processing like machining, polishing, or bead blasting achieves smooth finishes. The required finish depends on the part’s function.

(when did metal start to get 3d printed)

7. Are there design restrictions? Fewer than traditional methods! But overhanging features usually need temporary support structures during printing. These supports must be removed later. Designers must consider how heat flows and stress builds during printing. This avoids warping or cracking. Software helps optimize designs for printing success.