Discover a professional 3D printing powder supplier

The Spark That Lit the Fire: When Did 3D Steel Printing Actually Remove? .

(when was 3d metal printing developed)

The idea of developing points layer by layer isn’t brand-new. People fantasized regarding 3D printing for years prior to it became real. Printing with plastic ordered headings initially. It was interesting, valuable for models and enjoyable designs. Yet a larger inquiry melted in engineers’ minds: could we print with metal? Metal is tough, strong, important for important components in equipments, planes, even inside our bodies. So, when did this effective concept, 3D steel printing, in fact come to be a functioning technology?

The tale starts remarkably very early. The first real triggers flew back in the 1990s. Think about that. Computer systems were large. The internet was young. Yet, scientists were currently trying out. They weren’t developing rocket engines then. They concentrated on showing the idea. Could a maker deposit metal powder and fuse it specifically with a laser or electron light beam? The answer, gradually and fastidiously, was yes. Early patents turned up. Makers allowed, expensive, and incredibly slow. The components they made were commonly rough, loaded with problems. Yet the capacity was obvious. This was the silent, abrasive beginning– the stimulate in the lab.

Rapid onward to the very early 2000s. This is when points started warming up substantially. Secret patents began running out. This unlocked. Extra companies delved into establishing and marketing metal 3D printers. The innovation improved names also: Additive Manufacturing (AM) or Direct Steel Laser Sintering (DMLS). Materials enhanced. Machines became much more dependable. Speed boosted, a little bit. Industries like aerospace and medical implants took major notice. They saw a means to make components impossible with old techniques. This was the moment 3D metal printing shifted. It relocated from a lab interest to a genuine industrial device. The fire was catching.

Key Item Keywords: 3D Steel Printing.

1. What is 3D Metal Printing? .

Neglect paper printers. Neglect plastic trinkets. 3D steel printing is different. It builds solid, usable steel objects directly from an electronic design documents. Think of it like highly specific welding, done layer by tiny layer. It utilizes powerful lasers or electron light beams. These beam of lights act like tiny torches. They melt or fuse great steel powder together. The powder can be titanium, stainless-steel, aluminum, nickel alloys, also gold. The maker adheres to the computer instructions precisely. It spreads a slim layer of powder. The laser or light beam zaps the powder where the strong component must be. The system reduces a little. An additional layer of powder spreads. The laser merges once more, bonding to the layer below. This repeats hundreds or hundreds of times. Gradually, a total steel part arises from the powder bed. It’s not magic. It’s innovative engineering. It lets us produce shapes typical metalworking can not touch.

2. Why Make Use Of 3D Metal Printing? .

Why choose this new way over forging or machining? Several big factors stick out. First, layout flexibility is significant. Old techniques commonly need basic shapes. They are very easy to reduce or mold. 3D metal printing makes fun of complexity. It makes detailed latticeworks, internal networks, hollow frameworks quickly. Think about a cooling flow inside a wind turbine blade. Machining that is almost difficult. Printing it is straightforward. Second, it loses much less material. Traditional machining carves away a large block of metal. Perhaps 80% winds up as scrap chips. Printing primarily utilizes only the powder required for the component itself. This conserves expensive metals. Third, it enables part consolidation. As opposed to welding ten pieces together, print one solitary, more powerful piece. This minimizes weak points. 4th, it enables quick prototyping and quick layout modifications in steel. Required a new brace tomorrow? Publish it. Finally, it can make custom-made parts economically. Believe individualized clinical implants completely suitable one client’s bone. These advantages resolve genuine manufacturing frustrations.

3. How Does 3D Metal Printing Work? .

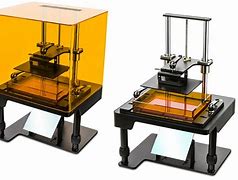

A number of approaches exist, however two dominate. The initial is Powder Bed Blend (PBF). This consists of DMLS and SLM (Careful Laser Melting). A chamber holds a construct system. A thin layer of metal powder tops it. A high-power laser scans across the powder. It melts the powder bits precisely where the part cross-section is defined. The melted particles fuse with each other and solidify. The system lowers. A new layer of powder spreads. The laser scans again, merging the brand-new layer to the one listed below. This repeats up until the component is total. The extra powder sustains the part throughout printing. It obtains recycled later. The 2nd major approach is Directed Energy Deposition (DED). Right here, a nozzle sprays steel powder (or often wire) straight onto the build surface. A laser or electron beam of light thaws the material right at the point of deposition. DED is terrific for adding features to existing components or repairing worn components. It’s also quicker for larger, simpler shapes. Both approaches require mindful control of temperature and atmosphere to stop oxidation and make sure solid bonds.

4. Applications of 3D Metal Printing .

Where is this technology making waves? Anywhere demanding high performance and facility geometry. Aerospace is a leader. Firms publish light-weight, ultra-strong braces, gas nozzles, and wind turbine blades. These components frequently consider less and do much better than traditionally made ones. The clinical field accepts it. Surgeons make use of patient-specific implants for knees, hips, and heads. Dental laboratories publish crowns and bridges. Biocompatible titanium is perfect for this. The automobile market utilizes it for premium auto racing components, personalized elements, and prototyping new engine designs faster. Device and die makers enjoy it. They publish molds with conformal air conditioning channels. These channels adhere to the mold form closely. They cool the molded plastic component much faster and a lot more uniformly. This cuts cycle times drastically. Power business print complicated components for generators and oil/gas equipment. Jewelers develop intricate layouts impossible to cast. Even art and style discover its sculptural potential. The applications keep expanding.

5. 3D Metal Printing FAQs .

People have numerous inquiries about this modern technology. Below are common ones:.

Is it strong? Yes, published metal parts can be very solid. Done right, the product homes match or perhaps surpass actors steel. Occasionally they get close to created metal. Testing is critical.

Is it costly? The makers and metal powder cost a whole lot. For basic parts, traditional approaches are more affordable. For complicated, custom, or lightweight-optimized components, printing typically saves cash overall. Less waste, less assembly, far better efficiency add up.

How smooth is the surface area? Straight off the printer, parts are rough. They have a texture like great sandpaper. Many applications require ending up. Machining, brightening, or grain blasting smooths the surface. This adds cost and time.

What about size limitations? Build volumes are boosting. Printers exist that make components meters long. But the majority of commercial devices deal with components approximately the size of a big shoebox. Larger parts need larger, a lot more costly machines.

(when was 3d metal printing developed)

Can I print any kind of metal? Not yet. Common printable metals consist of titanium alloys (Ti6Al4V), stainless steels (316L, 17-4PH), light weight aluminum alloys (AlSi10Mg), nickel-based superalloys (Inconel 718, 625), cobalt-chrome, and some device steels. Research study expands this checklist continuously. The steel must be readily available as great, spherical powder and behave well under the laser or beam of light.