Discover a professional 3D printing powder supplier

** Who Dreamed Up 3D Metal Printing First? **.

(when was 3d metal printing invented)

Envision an equipment that can transform digital plans right into solid metal items. No hammers, no molten steel wallowing– simply layers of material accumulating like magic. This isn’t science fiction. It’s 3D steel printing. But when did this futuristic idea become real? Allow’s go into the story.

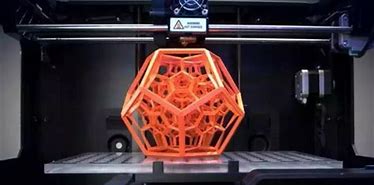

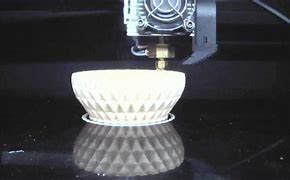

The roots of 3D steel printing go back to the 1980s. Back then, individuals were currently experimenting with methods to develop items layer by layer. The earliest 3D printers used plastic. They functioned by melting plastic and forming it right into slim layers. Metal was more difficult. Thawing metal necessary means a lot more warmth, and controlling it was a big obstacle.

The actual advancement came in 1994. A team of scientists at the Fraunhofer Institute in Germany cracked the code. They created a process called “selective laser sintering” (SLS). Here’s how it functioned: a high-powered laser aimed at a bed of steel powder. The laser melted the powder in precise places, integrating it into strong forms. Layer by layer, a steel things materialized. This was the initial true 3D steel printing method. It had not been best. The makers were slow, and the parts often required added finishing. However it verified steel could be published.

Around the exact same time, various other inventors were playing with similar ideas. In the U.S., a guy called Carl Deckard filed a license for SLS modern technology in the late 1980s. His job prepared for later metal-printing systems. On the other hand, companies like EOS and Arcam started developing industrial makers in the 1990s. These early printers were mostly made use of for models. They were too costly and sluggish for mass production.

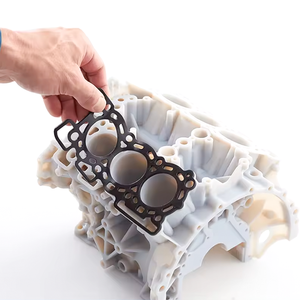

The 2000s brought large enhancements. Lasers obtained more powerful and extra precise. Software program came to be smarter, letting engineers style complex parts that were difficult to make with typical methods. Aerospace business took notice. They required lightweight, strong components for jets and rockets. 3D metal printing fit the bill. By the 2010s, titans like NASA and SpaceX were making use of published steel parts in real objectives.

Medicine followed suit also. Specialists began using 3D-printed titanium implants. These customized parts fit people completely, lowering surgical procedure time and recovery. Also the apparel industry got imaginative. Developers published detailed metal precious jewelry, mixing art with design.

Today, 3D steel printing keeps advancing. New strategies like “binder jetting” quicken the procedure by gluing metal particles together before melting them. Companies trying out everything from aluminum to gold. The objective is simpler: make steel printing quicker, more affordable, and available to every person.

(when was 3d metal printing invented)

Early leaders might not have actually guessed how far their inventions would go. From confusing laboratory equipments to manufacturing facilities printing rocket engines, 3D steel printing reshaped how we develop points. It’s a suggestion that also the wildest concepts– like turning powder right into precision parts– can come to be reality with sufficient time and creativity.