Discover a professional 3D printing powder supplier

The Dawn of Metal 3D Printing: When Did It All Begin? .

(when was the first time metal was used in 3D printing)

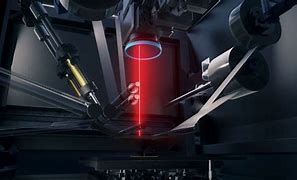

Steel 3D printing revolutionized manufacturing. The initial effective steel 3D print occurred in 1994. A German study team utilized a laser to melt metal powder layer by layer. This approach was called “selective laser melting.” It noted the birth of steel additive production. Early experiments dealt with obstacles. Melting steel needed extreme heat. Controlling the process required accuracy. Yet this advancement opened up doors to impossible styles.

1. What is Steel 3D Printing? .

Metal 3D printing develops things from metal powders or cables. It makes use of lasers, electron light beams, or binders. Layer by layer, it merges product into strong forms. Unlike plastic 3D printing, steel approaches need high temperatures. Some equipments reach over 1,000 ° C. Common techniques include Direct Steel Laser Sintering (DMLS) and Electron Beam Of Light Melting (EBM). These processes create dense, strong parts. Industries utilize it for complex elements. Assume aerospace brackets or medical implants. It turns digital blueprints right into concrete metal products.

2. Why Usage Steel in 3D Printing? .

Metal provides strength plastic can not match. It deals with warm, pressure, and stress and anxiety. Traditional metalworking subtracts product. Cutting, drilling, milling waste resources. 3D printing includes material just where required. This reduces waste by as much as 90%. Style flexibility is one more win. Designers make hollow structures or inner networks. These features boost performance. Weight goes down without compromising toughness. Personalization becomes very easy. Dental professionals produce patient-specific titanium jaws. Car manufacturers examination light-weight prototypes faster. Steel 3D printing resolves problems old approaches couldn’t.

3. Exactly How Does Steel 3D Printing Job? .

Initially, a 3D version is sliced into electronic layers. Inside the printer, metal powder spreads out very finely. A laser or light beam strikes the powder. It melts precise places adhering to the layer design. The develop plate lowers slightly. New powder coats the surface. The laser repeats melting. This cycle continues up until the component is done. After printing, components cool down in regulated chambers. Assistance structures prevent bending. These obtain eliminated later. Post-processing includes sandblasting or warmth therapy. It makes certain stamina and level of smoothness. Equipments run in inert gas environments. Oxygen ruins metal fusion. Nitrogen or argon maintains prints pure.

4. Applications of Metal 3D Printing .

Aerospace giants use it for gas nozzles. GE’s 3D-printed nozzle weighs 25% much less. It survives extreme engine heat. Medical fields count on titanium implants. Hip joints fit together perfectly with client bones. Biocompatible metals incorporate with tissue. Automotive brand names print lightweight pistons. These increase engine performance. Formula 1 autos shave seconds with customized parts. Jewelers craft elaborate gold rings. No molds or sculpting required. Even art installments use metal prints. Carvers make impossible geometries. Military applications consist of sturdy weapon elements. Guns stand up to repeated use. Power firms fix turbines faster. On-site printers make substitute blades.

5. Frequently Asked Questions about Metal 3D Printing .

Is it solid like created steel? .

Yes. Printed parts match or surpass conventional strength. Testing programs high exhaustion resistance. They sustain stress cycles consistently.

What steels work best? .

Titanium, light weight aluminum, stainless-steel, and cobalt chrome control. Titanium suits aerospace. Steel fits industrial devices. Silver or gold help fashion jewelry.

Exactly how pricey is it? .

Machines cost $100,000 to over $1 million. Product rates build up. However it saves money for facility, low-volume items. No tooling cuts initial costs.

Can it publish large things? .

Print beds now get to 2 meters. Larger parts get published in sections. Welding or bolting joins them.

Is it safe? .

Operators handle great powders carefully. Dust poses surge dangers. Shut makers and ventilation manage this. Training prevents accidents.

Are there size restrictions? .

Printers deal with details smaller than a human hair. Wall thicknesses down to 0.3 mm job. Overhangs need assistances. Designs avoid severe overhangs.

How fast is it? .

Printing takes hours or days. Speed depends on component size and intricacy. Post-processing includes time. However it defeats months of traditional machining.

Do all industries use it? .

(when was the first time metal was used in 3D printing)

Not yet. Automation prefers casting. But for prototypes, custom tools, or one-of-a-kind parts, it’s unequaled. Fostering expands yearly.