Discover a professional 3D printing powder supplier

Okay, here is the reworded title and the article crafted according to your requirements.

(where to get a small metal part 3d printed 3d 3d metal printing companies near me)

Title: The Quest for Tiny Titans: Your Guide to Small Metal Part 3D Printing Near You

Article: .

You need a small steel part. Possibly it’s a replacement equipment for an old gizmo. Perhaps it’s a special part for your brand-new invention. Possibly it’s a customized bracket. You require it strong. You require it precise. You need it made in steel. And you require it quickly. Large factories aren’t interested. Typical machining costs too much. What do you do? The answer is tiny steel part 3D printing. This innovation is changing the ready personalized metal components. Let’s learn where to get it done near you.

1. What is Small Steel Component 3D Printing? .

Think of it as developing small metal items layer by layer. It uses computer system styles. It thaws fine steel powder with lasers or binds it with adhesives. It builds the component up little by little. This isn’t your normal plastic 3D printer. This is commercial equipment. It takes care of products like stainless-steel, titanium, aluminum, and extra. The “little” component is crucial. These printers stand out at making complicated shapes. They make forms that are difficult or impossible with old approaches. They make little batches. They make one-off pieces. They are perfect for prototypes, custom-made tools, or specialized components. You do not require massive manufacturing runs. You just need that one excellent little metal piece.

2. Why Choose Little Metal Component 3D Printing? .

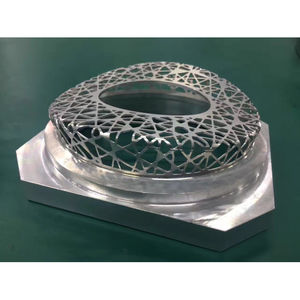

Here’s the important things. Making small metal components generally is difficult. Machining calls for special setups. It typically loses a great deal of product. Casting demands molds. Mold and mildews cost a lot for simply one component. Small steel component 3D printing fixes these troubles. Style liberty is big. You can create internal channels. You can make lattice frameworks. You can make natural forms. All are possible. This brings about lighter components. It causes more powerful parts. It brings about parts that function better. Speed is one more big plus. You can go from computer file to end up part rapidly. This is excellent for examining concepts. It’s fantastic for repairing damaged tools quick. Expense is additionally a variable. For little quantities or complicated styles, 3D printing is frequently less costly. You save money on tooling. You reduce product waste. You get your component quicker.

3. Exactly how Do You Obtain a Small Steel Component 3D Printed? .

Obtaining your small metal component made involves a couple of actions. Initially, you need a 3D design. This is a digital blueprint. You can produce it utilizing CAD software application. Perhaps you already have the documents. Maybe you require help developing it. Next, locate a provider. Seek “steel 3D printing solution” or “additive production near me”. Search online. Use maps. Ask for suggestions. Inspect their capacities. Can they manage the product you require? Can they make the dimension and intricacy you require? What concerning surface finish? What concerning resistances? Get in touch with a couple of companies. Send them your design data. They will certainly examine it. They will look for printability. They might suggest adjustments. They will certainly give you a quote. They will tell you the timeline. As soon as you agree, they will print your part. They will post-process it. This could involve support elimination. It may involve warmth therapy. It may include polishing. Then, you obtain your finished little metal part.

4. Where Are Little Metal Components 3D Printed Utilized? .

These little metal wonders are almost everywhere. Look at aerospace. They make light-weight brackets inside satellites. They make complex gas nozzles in jet engines. The clinical field utilizes them a great deal. Think of custom surgical overviews. Consider patient-specific implants. Think about delicate instruments. The automobile sector advantages as well. Customized components for assembly lines. Prototypes for new engine parts. Efficiency components for auto racing. Consumer products use them. Premium watch components. Distinct precious jewelry items. Resilient components for electronic devices. Commercial tools depends on them. Specialized sensors housings. Durable tooling inserts. Substitute components for hard-to-find machines. Even research study laboratories use them. Personalized laboratory devices. Experimental components. The possibilities are substantial. Practically any industry needing strong, small, custom metal parts can use this innovation.

5. Frequently Asked Questions Concerning Small Steel Component 3D Printing .

People usually have inquiries. Below are some common ones.

Exactly how little can the parts be? Very little. Attributes down to fractions of a millimeter are feasible. Assume tiny gears. Believe complex latticework frameworks. The limits rely on the certain printing technology and material.

Just how strong are the parts? They are really solid. They are comparable to generally made steel components. In some cases they are stronger. This relies on the material. It depends upon the printing process. It depends on the post-processing.

What steels can be utilized? Lots of metals are available. Usual ones include stainless-steels (like 316L, 17-4 PH). Others are titanium alloys (like Ti6Al4V). Light weight aluminum alloys (like AlSi10Mg) are popular. Tool steels, cobalt-chrome, and even rare-earth elements like gold are choices.

Is it expensive? Price varies. It depends on part size. It relies on complexity. It depends upon product. It relies on amount. For one-off facility components or tiny sets, it’s often cost-effective. It beats the cost of making mold and mildews or special tooling.

(where to get a small metal part 3d printed 3d 3d metal printing companies near me)

What concerning surface area finish? Parts appear of the printer with a rough surface area. It looks a little bit like great sandpaper. Post-processing can smooth this. Choices include sandblasting, brightening, machining, or covering. The degree of level of smoothness depends upon the finish you pick and pay for.