Discover a professional 3D printing powder supplier

Allow’s discuss steel 3D printing. It sounds like something from sci-fi, doesn’t it? Structure facility steel parts directly from a computer file. No giant mold and mildews. No mountains of steel chips. Just layer by layer, producing items that were once difficult. However just what is it? How does it function? And why should any person care? Allow’s break it down.

(which process is metal 3d printing)

What is Metal 3D Printing? .

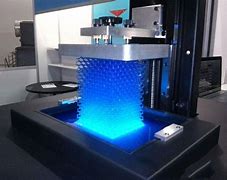

Metal 3D printing is a method to make solid steel components. It constructs them up layer by layer. Think about it like constructing with LEGO bricks, however extremely small and making use of lasers or electron beam of lights as opposed to your hands. It starts with an electronic 3D version. This design gets sliced right into thin layers by unique software application. The 3D printer after that follows these guidelines. It includes product one little layer at a time. We melt steel powder or cable specifically where required. Each layer bonds to the one below it. Gradually, a complete, practical steel things appears. This is very various from reducing metal away like machining. It’s also various from putting liquified metal right into a mold like casting. Steel 3D printing is additive production for metal. It opens up new style opportunities.

Why Choose Metal 3D Printing? .

So why usage metal 3D printing? It uses distinct benefits. The most significant reason is layout flexibility. Conventional production approaches usually restrict what you can make. Think about intricate shapes, interior networks, or hollow structures. These are tough or costly to produce conventionally. Metal 3D printing manages them conveniently. It constructs complexity totally free. You can integrate numerous parts into one single published piece. This decreases assembly time. It likewise makes the part lighter and stronger. Weight reduction is critical in markets such as aerospace and auto. Much less weight indicates much better fuel performance. One more large advantage is personalization. Making one unique part is equally as simple as making a hundred similar ones. This is best for clinical implants tailored to a particular patient. It’s likewise fantastic for developing customized tools or extra parts quickly. Metal 3D printing can additionally minimize waste. It just utilizes the material needed for the part itself. There’s much less scrap steel contrasted to machining. Ultimately, it enables rapid prototyping and manufacturing. You can test styles much faster. You can get parts right into solution quicker.

Exactly How Does Metal 3D Printing Job? .

The magic occurs in a few different ways. A number of processes exist. One of the most typical ones use steel powder and high-energy beams. Let’s consider 2 prominent techniques. The first is Direct Metal Laser Sintering or DMLS. In some cases it’s called Selective Laser Melting or SLM. The names are commonly used mutually. In this process, a thin layer of great steel powder is spread across a construct system. An effective laser scans across the powder bed. It complies with the pattern for that specific layer. The laser melts the metal powder bits. They fuse with each other and to the layer listed below. The develop platform lowers a little. A new layer of powder is spread. The laser melts the next layer. This repeats till the whole component is total. The unused powder supports the part during printing. After printing, the component is removed from the powder bed. It usually requires support frameworks removed. It likewise usually calls for warm treatment for strength. The second common technique is Electron Beam Melting or EBM. This functions likewise to DMLS/SLM. Yet it utilizes an electron beam in a vacuum chamber as opposed to a laser. The electron light beam melts the steel powder. EBM generally develops components quicker. It likewise creates parts at very high temperatures. This can lead to various material residential properties. Various other approaches exist too. Some utilize steel powder bound in plastic, then sintered. Others spray metal droplets or thaw metal cord directly. Each approach has its toughness. DMLS/SLM and EBM are the leaders for high-strength, complex metal parts.

Applications of Metal 3D Printing .

Where do we see steel 3D printing at work? It’s appearing everywhere! The aerospace market enjoys it. Weight is everything when you’re flying. Steel 3D printing develops lighter, more powerful components. Think wind turbine blades, gas nozzles, and structural braces. These parts usually have complicated interior air conditioning channels. These channels are impossible to device. Medical and dental fields additionally accept it. Custom hip implants, knee substitutes, and back cages fit individuals completely. Oral labs utilize it for crowns, bridges, and orthodontic tools. The vehicle industry uses it too. Race teams publish lightweight, high-performance parts. Producers develop intricate jigs and fixtures for assembly lines. Also the energy industry benefits. Firms publish components for generators and warmth exchangers. These parts withstand severe conditions. Jewelers are discovering it for complex designs. Artists utilize it to create one-of-a-kind sculptures. Toolmakers publish customized inserts and molds with air conditioning networks. This assists plastics cool down quicker during shot molding. The applications maintain growing. Steel 3D printing resolves issues traditional methods can’t.

FAQs Concerning Steel 3D Printing .

People have several inquiries regarding this innovation. Below are some common ones:.

Is steel 3D printing pricey? Yes, it can be expensive. The devices themselves are pricey. The steel powders are additionally expensive. Handling components after publishing adds price also. Nevertheless, for complex parts or reduced volumes, it can be less expensive than conventional techniques. The expense is boiling down as innovation breakthroughs.

What products can be published? Many steels work. Typical ones include stainless steel, titanium, light weight aluminum, nickel alloys like Inconel, and cobalt-chrome. Tool steels and precious metals like gold are likewise possible. Research study remains to expand the checklist. The product residential or commercial properties resemble generally made steel. Occasionally they are also better.

Just how strong are metal 3D printed parts? They are really solid. In fact, they can be as strong as components made by forging or casting. Occasionally they are more powerful. The key is proper style and adhering to the best procedure. Post-processing like warmth treatment is essential. It guarantees the steel reaches its complete prospective toughness.

Is the surface coating excellent? Right off the printer, the surface is frequently rough. It has a texture from the layered process. For many useful components, this serves. If a smooth coating is required, machining or polishing can be done afterwards. Think of it like finishing an actors component.

Are there dimension restrictions? Yes, however they are expanding. Current machines have build volumes varying from small (a few inches) to quite huge (several feet). Bigger devices are being developed. Large parts might be published in areas and joined. The innovation maintains pushing limits.

(which process is metal 3d printing)

Can it change typical manufacturing? Not entirely, and probably not quickly. It stands out at complex, low-volume, or customized parts. For basic forms produced in high quantities, methods like spreading or machining are commonly faster and less costly. Steel 3D printing is an additional effective tool in the manufacturing tool kit. It complements conventional techniques.