Reveles professionalis 3D printing pulveris elit

PARAMETERS FRUCTUS

Descriptio

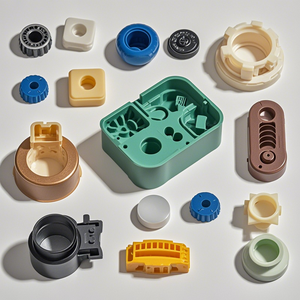

Overview of Milling Metal 3d Typographus Typographus 3d Officia Typographia CNC Apparatus Instrumentorum Industrialium Instrumentorum Instrumentorum

3D excudendi, Etiam quae ELOGIUM vestibulum, technologia transformativa est quae permittit creationem rerum trium dimensivarum deponendo materias iacuit per iacum secundum digitales designationes. This process opens up a new world of possibilities in product design, customization, et productio, revolutionizing various industries including healthcare, aerospace, eget, bona dolor, et plus.

Customization & Personalisation: One of the key advantages of 3D printing is its ability to create highly customized products tailored to individual needs or preferences, ex prothesium formare accessiones.

Complex Geometria: 3D excudendi excellit ad intricatas formas et geometrias producendas, quae maxime difficilia vel impossibilia sunt utentes modos conventionales fabricare., sicut cancellos internus structurae seu formae organicae.

Celeri Prototyping: Hoc signanter accelerat cyclum evolutionis producti, ut designatores et fabrum efficiat ut cito corporalia prototypa ad probationem et elegantiam producat..

In vestibulum: Technologiam sustinet parvam massam vel etiam productio una-off decurrit oeconomice, opus magnis inventariis reducendo et ad vestibulum justo in tempore permittens.

Materia diversitas: A materiae amplis potest esse in 3D printing, comprehendo materia plastica, metallis, ceramics, composita, ac etiam biomaterials, unumquodque unique proprietatibus pro specifica applications.

Reducitur meminisset: Ut vestibulum ars comparari subtractiva, 3D excudendi solum addit materiam ubi opus fuerit, ducens ad minus vastum et magis sustineri faciens processum.

Features of Milling Metal 3d Typographus Typographus 3d Officia Typographia CNC Apparatus Instrumentorum Industrialium Instrumentorum Instrumentorum

Design Flexibility: Technology dat effectionem consiliorum complexorum sine coercitionibus instrumentorum et formarum fabricandorum.

Eget Integration: Partes designari possunt cum features integralibus ut canales, cavitates, aut interlocking components, quae augendae functionality vel simpliciorem coetum.

STRUCTURA PERFUSORIUS: Provectus 3D technicis excudendis permittit ut structuras leves et validas structuras per optimized rationes et usum cancellorum structurarum seu materiarum compositarum..

Improved euismod: Per compositionem et structuram praecise moderantum materiam, 3D partes typis auctus mechanica exhibere possunt, scelerisque, aut electrica proprietatibus.

Sumptus-Efficiency pro Complexity: Dum 3D excudendi non semper certare cum massa productionis modi pro partibus simplicibus, magis magisque cost-efficax quam multiplicitas partium augetur.

Innovative Applications: Ex medicinae implantationibus quae anatomiam patientis perfecte aequant ad componentia aerospace quae pondus minuunt et efficientiam augent, 3D excudendi limites impellit quod possibile est in producto consilio et in engineering.

(Milling Metal 3d Typographus Typographus 3d Officia Typographia CNC Apparatus Instrumentorum Industrialium Instrumentorum Instrumentorum)

Specification of Milling Metal 3d printer prototype 3d printing services CNC machinery tools Industrial equipment components

Our steel 3D printing service builds strong, working models and components. We use special milling makers for this. These printers make things from steel powder. They melt the powder layer by layer. You get solid metal parts ultimately.

We deal with various steels. Steel, titanium, and light weight aluminum prevail choices. Each metal has its own strengths. Steel is tough. Titanium is light but solid. Aluminum is additionally light and good for many points. We assist select the most effective metal for your job.

The printed components are very precise. The makers are precise. They make complex shapes easily. This is tough for older methods. You get smooth surface areas usually. Much less extra job is needed later on. This conserves time and money.

Speed is very important. We obtain your components made quickly. Rapid manufacturing aids you test concepts quicker. It helps you obtain items to market much faster. We keep things moving.

Our solution links well with CNC machining. CNC equipments complete the published components. They reduced the parts to exact sizes. They make holes and strings. Both innovations work together smoothly. This gives you the best final product.

You obtain strong, reputable parts for market. These parts enter into machines and tools. They deal with hefty use. They perform well under stress. Our process makes this possible.

We concentrate on what industries need. Factories need components that last. They require parts that fit flawlessly. Our steel printing provides this. It resolves challenging production issues.

(Milling Metal 3d Typographus Typographus 3d Officia Typographia CNC Apparatus Instrumentorum Industrialium Instrumentorum Instrumentorum)

Applications of Milling Metal 3d printer prototype 3d printing services CNC machinery tools Industrial equipment components

Metal 3D printing solutions use effective tools for developing intricate steel parts. These printers develop parts layer by layer from steel powders. This innovation stands out at making models swiftly. Engineers can currently check layouts faster than in the past. Useful models are possible. These test parts function under actual problems. This aids discover style issues early. Repairing concerns early conserves time and money later. Milling steel 3D printed components is commonly needed. Printed surface areas may require smoothing. CNC machining facilities provide this completing. CNC devices precisely cut and form the steel. This ensures limited resistances and smooth surface areas. The combination is really reliable. 3D printing makes the complex shape. CNC machining adds the last precision. Custom tooling is one more excellent application. Manufacturing facilities need special jigs and fixtures. Steel 3D printing makes these devices quickly. It is much faster than traditional techniques. Manufacturing downtime obtains lowered. Tooling expenses likewise drop. Industrial equipment depends on strong components. Metal 3D printing builds these parts. It makes equipments, housings, and brackets. These parts encounter hefty lots and put on. The printed steel stands up to challenging atmospheres. Repairing old equipment is less complicated now. Obsolete parts are tough to discover. Printing replacements solves this problem. It keeps makers running longer. Short manufacturing runs advantage too. Making little sets with conventional devices is expensive. Printing these parts is a lot more cost-effective. Preparations get much shorter. Firms get their components much faster.

Turba Profile

3D Passionis Typographia est credita global chemicae materialis supplementum & manufacturer cum super XII annos experientia praebendo super summus qualis 3D excudendi pulveris et relativum products.

Comitatu habet professionalem technicam department et Quality CURATIO Department, instructi officinarum, et instructi ad probationes provectus apparatu et post-venditio Lorem ministerium centrum.

Si vos es vultus summus qualitas materiae et relativa products 3D excudendi, placet liberum contactus nos vel click in opus products ut inquisitionem mittat.

Solucionis Methodi

L/C, T/T, Occidentis Unionis, Paypal, Promeritum Pecto etc.

shipment

Uit per mare posset, per aerem, aut revelare ASAP quamprimum recipere accepta.

5 FAQs of Milling Metal 3d printer prototype 3d printing services CNC machinery tools Industrial equipment components

What materials can you use for metal 3D printed prototypes? We print mostly with stainless steel, aluminum, and titanium. These metals are strong. They work well for many industrial parts. We choose the best metal for your project’s needs.

How good is the surface finish? The finish straight off the printer is rough. It looks layered. We offer CNC machining after printing. This step cleans and smooths the surfaces. It makes the part look and feel like a final product.

How precise is the printing? We can make parts very close to your design. Our machines hold tight tolerances. This means parts fit together correctly. It is good for testing how things work. We check dimensions carefully.

How long does it take to get a prototype? Time depends on the part size and complexity. Simple parts are faster. We often finish small parts in a few days. Bigger or complex parts take more time. We give you a clear timeline upfront.

Is it expensive? Metal printing costs more than plastic printing. It uses special machines and materials. The price depends on the metal type, part size, and finish level. We provide quotes quickly. It saves money compared to old ways for some complex parts.

(Milling Metal 3d Typographus Typographus 3d Officia Typographia CNC Apparatus Instrumentorum Industrialium Instrumentorum Instrumentorum)