Discover a professional 3D printing powder supplier

What Is a 3D Printed Bullet? .

(can you make a 3d printed bullet that would pierce metal?)

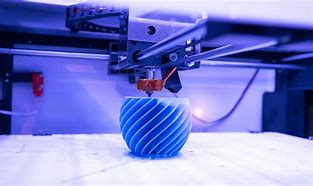

A 3D printed bullet is a projectile used additive production techniques as opposed to traditional metal spreading or machining. Many consumer-grade 3D printers make use of plastic filaments like PLA or ABS, so early efforts at publishing bullets were mainly plastic shells meant to hold gunpowder and a guide. These are not solid steel slugs. True bullets that pierce steel require high density, firmness, and architectural integrity– qualities most plastics simply do not have. Some progressed arrangements utilize metal 3D printing, but those need commercial machines and specialized products. You can learn more concerning the sort of products used in steel 3D printing by visiting this overview on steel printing sustains.

Why Would Certainly A Person Try to 3D Print a Bullet? .

People discover 3D printed bullets for different factors. Some are curious enthusiasts examining the limits of their home printers. Others might have an interest in custom-made ammunition for particular niche applications, like historic reenactments or low-power air guns. In rare situations, people seek methods to bypass gun control regulations– however this is both hazardous and illegal in lots of places. The fact is, making a useful bullet that can puncture steel demands even more than a desktop computer printer and spool of filament. Even if you take care of to shape something that looks like a bullet, it likely will not endure the eruptive force of firing, let alone pass through steel or light weight aluminum. For those experimenting with metal surfaces on published parts, paint methods may aid with look– but not efficiency. See how others deal with surface therapies in this blog post on painting metal filament.

How Is a Bullet Normally Made– and Can 3D Printing Match It? .

Typical bullets start as lead cores, usually jacketed in copper. They are formed under high stress to guarantee uniform density and smooth surface areas. This process gives them the mass and hardness needed to stay undamaged throughout high-speed traveling and effect. In contrast, conventional 3D printed objects are layered, which creates weak points in between layers. Plastic bullets ruin conveniently when fired. Steel 3D printing exists– it utilizes lasers to fuse powdered steels like stainless-steel or titanium– but these systems cost 10s of thousands of bucks and need experienced handling. Even then, published metal components typically call for warmth therapy and finishing to reach the toughness of forged or cast equivalents. If you ever deal with steel prints, eliminating them from the construct plate safely is crucial. Tips for that procedure are shared in this practical post on separating steel prints.

Applications of 3D Printed Projectiles (Realistic Ones) .

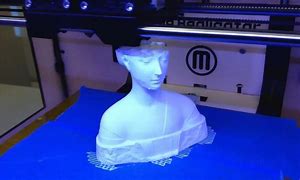

Forget piercing armor– real-world usages for 3D printed “bullets” are much more minimal and useful. Airsoft and paintball players in some cases publish customized coverings or non-lethal rounds for fun or prototyping. Filmmakers might utilize published dummy rounds for risk-free props that look actual on camera. Designers likewise check interior ballistics using printed elements to simulate exactly how cartridges behave before ignition. None of these applications require the projectile to really pass through metal. Instead, they rely upon shape, weight simulation, or visual accuracy. Severe protection or searching applications still depend totally on factory-made ammo. The concept of a plastic bullet punching through steel belongs in action films, not reality.

Frequently Asked Questions About 3D Printed Bullets and Steel Penetration .

Can a plastic 3D published bullet pierce metal? No. Plastic lacks the thickness and solidity needed to penetrate even thin sheet steel. At best, it may damage soft aluminum if fired at extremely high rate– yet it would likely disintegrate on impact.

Is it legal to 3D print bullets? Laws vary by nation and state. In the U.S., federal law enables self-made ammunition for individual usage, but some states prohibit untraceable or plastic firearms and elements. Always check local regulations before attempting anything pertaining to weapons.

Can steel 3D printing produce actual bullets? Technically yes, however it’s impractical for the majority of people. Industrial steel printers can create thick, strong components, yet the price, know-how, and post-processing required make it much less reliable than acquiring standard ammunition.

Do published bullets work in real weapons? Partially. Some lovers have actually printed plastic cartridge situations that hold real guides and powder, however the bullet itself is normally still a typical steel slug. Terminating a completely plastic projectile from an actual firearm is dangerous and ineffective.

Exist any type of risk-free experiments for newbies? Yes. You can publish dummy rounds for display or education. Simply never fill them with propellant. Concentrate on discovering ballistics, products, and safety and security– out attempting to construct weapons in the house.

What products give the best outcomes for published projectiles? For aesthetic designs, PLA or PETG job penalty. If you want a metallic look, consider metallic-infused filaments– but keep in mind, they are still primarily plastic. True efficiency needs actual metal, which isn’t practical on customer printers.

(can you make a 3d printed bullet that would pierce metal?)

Where can I discover more regarding 3D printing with metal-like products? Start with resources like this overview on painting metallic filament to comprehend surface area choices, and check out technical information in this summary of steel printing supports.