Discover a professional 3D printing powder supplier

PRODUCT PARAMETERS

Description

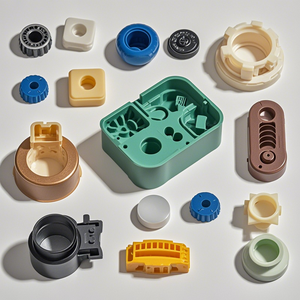

Overview of 316L slm printing rapid prototype metal 3d printing service

3D printing, also known as additive manufacturing, is a transformative technology that allows the creation of three-dimensional objects by depositing materials layer by layer based on digital designs. This process opens up a new world of possibilities in product design, customization, and production, revolutionizing various industries including healthcare, aerospace, automotive, consumer goods, and more.

Customization & Personalization: One of the key advantages of 3D printing is its ability to create highly customized products tailored to individual needs or preferences, from prosthetics to fashion accessories.

Complex Geometry: 3D printing excels at producing intricate shapes and geometries that would be extremely challenging or impossible to manufacture using conventional methods, such as internal lattice structures or organic forms.

Rapid Prototyping: It significantly speeds up the product development cycle by enabling designers and engineers to quickly produce physical prototypes for testing and refinement.

On-Demand Manufacturing: The technology supports small-batch or even one-off production runs economically, reducing the need for large inventories and allowing for just-in-time manufacturing.

Material Diversity: A wide range of materials can be used in 3D printing, including plastics, metals, ceramics, composites, and even biomaterials, each offering unique properties for specific applications.

Reduced Waste: As compared to subtractive manufacturing techniques, 3D printing only adds material where needed, leading to less waste and a more sustainable manufacturing process.

Features of 316L slm printing rapid prototype metal 3d printing service

Design Flexibility: The technology enables the realization of complex designs without the constraints of traditional manufacturing tools and molds.

Functional Integration: Parts can be designed with integrated features such as channels, cavities, or interlocking components, which can enhance functionality or simplify assembly.

Lightweight Structures: Advanced 3D printing techniques allow for the creation of lightweight yet strong structures through optimized designs and the use of lattice structures or composite materials.

Improved Performance: By precisely controlling material composition and structure, 3D printed parts can exhibit enhanced mechanical, thermal, or electrical properties.

Cost-Efficiency for Complexity: While 3D printing may not always compete with mass-production methods for simple parts, it becomes increasingly cost-effective as the complexity of the part increases.

Innovative Applications: From medical implants that match a patient’s anatomy perfectly to aerospace components that reduce weight and increase efficiency, 3D printing pushes the boundaries of what’s possible in product design and engineering.

(316L slm printing rapid prototype metal 3d printing service)

Specification of 316L slm printing rapid prototype metal 3d printing service

This service gives 316L stainless-steel prototypes used Selective Laser Melting (SLM) innovation. The material is understood for high rust resistance, stamina, and durability. It fits parts revealed to rough environments like chemicals, deep sea, or severe temperatures. SLM builds parts layer by layer from fine metal powder. The procedure guarantees precise geometries, tight resistances, and intricate inner functions typical techniques can not achieve.

Layer density ranges between 20-50 microns. This enables thorough styles with smooth surfaces. Components usually accomplish dimensional precision within ± 0.1 mm. Post-processing alternatives include warm treatment, machining, brightening, or covering to satisfy specific requirements. The service supports prototypes for functional testing, customized tools, or end-use components.

316L SLM parts work well in industries such as medical, aerospace, auto, and industrial equipment. Usual applications consist of surgical tools, fluid system components, engine components, and light-weight architectural braces. The modern technology makes it possible for layouts with interior networks, lattices, or hollow frameworks to lower weight without sacrificing strength.

Material homes consist of a minimum tensile strength of 520 MPa and return strength of 210 MPa. Thickness gets to over 99%, making certain near-full strength. All parts go through high quality checks like aesthetic examination, dimensional verification, and X-ray testing for internal issues.

Lead times depend upon part dimension and complexity. Tiny prototypes may deliver in 3-5 days. Bigger orders call for 1-2 weeks. Data accepted include action, STL, or IGES formats. Layout guidelines help optimize wall thickness, support frameworks, and orientation for printing success.

Expense aspects consist of product quantity, printing time, and post-processing. The service provides batch manufacturing for bulk orders. Custom-made material blends or accreditations like ISO 9001 are readily available on demand. Assistance groups help with layout feedback, product option, and project timelines.

Experience testing is recommended for important applications. Repetitive modifications ensure last components fulfill performance standards.

(316L slm printing rapid prototype metal 3d printing service)

Applications of 316L slm printing rapid prototype metal 3d printing service

316L SLM printing is a metal 3D printing solution used to develop quick prototypes and practical parts. This technique functions by thawing stainless-steel powder layer by layer with a laser. The outcome is solid, in-depth components resistant to deterioration and high temperatures. Industries like aerospace, clinical, automobile, and commercial manufacturing use this technology for its precision and adaptability.

Medical applications consist of medical devices, implants, and oral tools. 316L stainless steel is biocompatible, making it safe for body contact. Customized implants customized to patient anatomy enhance medical results. Medical devices made by doing this are resilient and simple to sterilize.

Aerospace companies make use of 316L SLM printing for lightweight, high-strength parts. Engine parts, brackets, and heat exchangers prevail instances. These parts deal with severe stress and warm during trips. Conventional production struggles with complicated styles, however 3D printing accomplishes them successfully.

Automotive designers depend on 316L prototypes to check brand-new designs swiftly. Customized exhaust systems, fuel injectors, and sensor real estates are generated with marginal waste. The material’s deterioration resistance fits parts exposed to harsh chemicals or climate. Rapid prototyping reduces growth cycles, assisting carmakers launch items faster.

Industrial equipment gain from 316L’s wear resistance. Gears, shutoffs, and pump elements last much longer in demanding settings. Repairing old machinery is less complicated with 3D-printed replacement components. Manufacturing facilities lower downtime by printing components on-site rather than waiting for deliveries.

Personalized projects likewise use this solution. Artists develop metal sculptures with intricate information. Designers evaluate architectural versions with scaled steel parts. Enthusiasts construct high-performance tools for specific niche applications. The innovation supports low-volume production without high tooling prices.

316L SLM printing provides design freedom. Complex internal networks or lattice structures enhance part efficiency. Designers test several versions promptly. Product waste is lower compared to standard machining. Prices drop for tiny batches or one-off tasks.

The procedure suits parts requiring limited tolerances. Slim wall surfaces, great textures, and hollow sections are possible. Post-processing like brightening or covering boosts surface quality. Industries embrace this method to remain competitive in fast-paced markets.

Company Profile

3D Printing Passion is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality 3D printing powder and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality 3D printing materials and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of 316L slm printing rapid prototype metal 3d printing service

What is 316L SLM metal 3D printing?

316L SLM printing uses a laser to melt stainless steel powder layer by layer. This method builds precise, strong metal parts. It works well for prototypes or custom components needing high corrosion resistance.

Why pick 316L SLM over traditional manufacturing?

This process makes complex shapes faster. Traditional methods like CNC machining take longer for intricate designs. SLM reduces material waste. It suits small batches or one-off projects.

What industries use 316L SLM-printed parts?

Aerospace, medical, and automotive sectors rely on these parts. Surgical tools, engine components, and fluid systems often use 316L. The material handles harsh environments.

How accurate are 316L SLM-printed parts?

Tolerances typically reach ±0.1 mm. Surface roughness averages around 10-25 microns. Post-processing like machining or polishing improves smoothness.

How long does 316L SLM prototyping take?

Lead times vary. Simple parts ship in 3-5 days. Larger or complex designs take longer. Design validation, printing, and post-processing all affect timelines.

(316L slm printing rapid prototype metal 3d printing service)