Discover a professional 3D printing powder supplier

PRODUCT PARAMETERS

Description

Overview of 3d Printer Filament Machine 3d Printing Filament Extruder Plastic filament machine

3D printing, also known as additive manufacturing, is a transformative technology that allows the creation of three-dimensional objects by depositing materials layer by layer based on digital designs. This process opens up a new world of possibilities in product design, customization, and production, revolutionizing various industries including healthcare, aerospace, automotive, consumer goods, and more.

Customization & Personalization: One of the key advantages of 3D printing is its ability to create highly customized products tailored to individual needs or preferences, from prosthetics to fashion accessories.

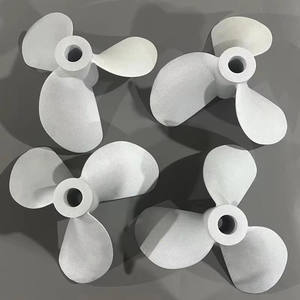

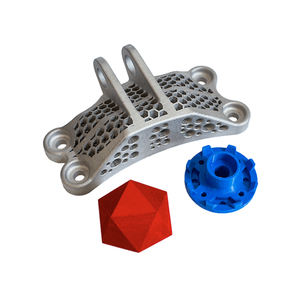

Complex Geometry: 3D printing excels at producing intricate shapes and geometries that would be extremely challenging or impossible to manufacture using conventional methods, such as internal lattice structures or organic forms.

Rapid Prototyping: It significantly speeds up the product development cycle by enabling designers and engineers to quickly produce physical prototypes for testing and refinement.

On-Demand Manufacturing: The technology supports small-batch or even one-off production runs economically, reducing the need for large inventories and allowing for just-in-time manufacturing.

Material Diversity: A wide range of materials can be used in 3D printing, including plastics, metals, ceramics, composites, and even biomaterials, each offering unique properties for specific applications.

Reduced Waste: As compared to subtractive manufacturing techniques, 3D printing only adds material where needed, leading to less waste and a more sustainable manufacturing process.

Features of 3d Printer Filament Machine 3d Printing Filament Extruder Plastic filament machine

Design Flexibility: The technology enables the realization of complex designs without the constraints of traditional manufacturing tools and molds.

Functional Integration: Parts can be designed with integrated features such as channels, cavities, or interlocking components, which can enhance functionality or simplify assembly.

Lightweight Structures: Advanced 3D printing techniques allow for the creation of lightweight yet strong structures through optimized designs and the use of lattice structures or composite materials.

Improved Performance: By precisely controlling material composition and structure, 3D printed parts can exhibit enhanced mechanical, thermal, or electrical properties.

Cost-Efficiency for Complexity: While 3D printing may not always compete with mass-production methods for simple parts, it becomes increasingly cost-effective as the complexity of the part increases.

Innovative Applications: From medical implants that match a patient’s anatomy perfectly to aerospace components that reduce weight and increase efficiency, 3D printing pushes the boundaries of what’s possible in product design and engineering.

(3d Printer Filament Machine 3d Printing Filament Extruder Plastic filament machine)

Specification of 3d Printer Filament Machine 3d Printing Filament Extruder Plastic filament machine

This equipment makes 3D printer filament. It transforms plastic materials right into thin strings used for printing. The machine collaborates with many kinds of plastic, like PLA, ABS, PETG, and TPU. It can handle various shades and blends. The machine heats up plastic to thaw it, then presses it with a nozzle to create the filament. The temperature level settings adjust conveniently for various products. This ensures the filament thaws correctly without burning or clogging.

The maker controls the filament density very specifically. It keeps the size in between 1.75 mm and 3.0 mm. Variations remain under 0.05 mm for smooth printing. The speed can be adapted to match user demands. It creates filament at 1-5 meters per minute. A cooling system solidifies the filament quickly after forming. This maintains the form consistent and solid.

Safety functions safeguard customers and the device. Overload security stops the electric motor if pressure gets expensive. Emergency situation buttons closed down the system fast if needed. The structure utilizes strong metal parts to last long. It remains stable even throughout long job sessions. Maintenance is easy, with easy accessibility to parts like nozzles and heaters.

The machine fits small factories, schools, or hobbyists. It makes customized filament less costly than purchasing prefabricated rolls. Users manage worldly kind, shade, and thickness. This adaptability supports innovative projects or particular commercial needs. Setup requires fundamental training, and the user interface is straightforward. Indicators show temperature, rate, and mistakes plainly.

Resilience is a key feature. The motor works for hours without overheating. Exchangeable components decrease long-lasting expenses. Sound degrees stay reduced during operation. The compact style fits in little spaces. Power use is effective, cutting power expenses.

Industries like prototyping, education, and manufacturing benefit from this maker. It supports eco-friendly recycling by recycling plastic waste. Users save money and minimize ecological influence. Dependability makes it a functional option for constant filament production.

(3d Printer Filament Machine 3d Printing Filament Extruder Plastic filament machine)

Applications of 3d Printer Filament Machine 3d Printing Filament Extruder Plastic filament machine

3D printer filament devices, likewise called 3D printing filament extruders or plastic filament equipments, transform raw plastic products right into useful filaments for 3D printing. These makers give users control over material choice, cost, and personalization. They work for lots of applications throughout various fields.

Hobbyists and small companies utilize these devices to develop customized filaments. Customers can blend colors or add special materials like timber or steel particles. This allows for individualized 3D prints without depending on store-bought options. Colleges and workshops make use of filament extruders for education. Pupils learn about material science by reusing old prints or testing brand-new plastic blends. This hands-on technique assists develop useful abilities.

Industrial settings rely upon filament equipments for quick prototyping. Companies produce specialized filaments customized to specific jobs, like high-strength components or versatile components. This cuts downtime from awaiting third-party suppliers. Recycling is another crucial use. Services decrease waste by grinding stopped working prints or scrap plastic right into pellets. The extruder transforms these pellets right into fresh filament, saving cash and supporting eco-friendly techniques.

Medical and engineering areas gain from specialized filaments. Makers can refine innovative products like biocompatible plastics or carbon-fiber-infused polymers. These products fit prosthetics, dental models, or light-weight aerospace parts. Filament extruders allow experts explore new blends for niche applications.

Filament equipments sustain small-scale manufacturing. Startups generate restricted batches of customized filaments without big manufacturing facility setups. Artists utilize them to produce textured or glow-in-the-dark materials for special sculptures or styles. The versatility of these equipments makes them useful for imaginative and technological tasks alike.

These applications demonstrate how 3D printer filament equipments adapt to different needs. They link gaps in between imagination, sector, and sustainability. Customers get independence from industrial providers while exploring cutting-edge material solutions.

Company Profile

3D Printing Passion is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality 3D printing powder and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality 3D printing materials and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of 3d Printer Filament Machine 3d Printing Filament Extruder Plastic filament machine

What materials work with a 3D printer filament extruder?

Most machines handle common plastics like PLA, ABS, PETG. Some support nylon or flexible TPU. Check the machine’s temperature limits. Higher temps let you process tougher materials. Always confirm material compatibility before use.

How consistent is the filament diameter?

Good extruders control diameter tightly. Sensors adjust extrusion speed automatically. Variations happen if settings are wrong or materials change. Calibrate the machine regularly. Test samples with calipers to ensure accuracy.

What’s the output speed of a filament extruder?

Speeds vary by model. Basic units produce 1-2 meters per minute. Industrial machines reach 5-10 meters. Speed depends on material type and nozzle size. Faster speeds might reduce precision. Balance speed with quality needs.

Is the machine safe to operate?

Safety features include overheating protection and emergency stops. Hot surfaces pose burn risks. Keep hands away during operation. Ventilate the area. Melted plastics release fumes. Follow the manual’s guidelines for safe use.

How much maintenance does it need?

Clean the nozzle after each use to prevent clogs. Lubricate moving parts monthly. Check screws and belts for wear. Replace damaged parts quickly. Storage matters. Keep the machine dry and dust-free. Maintenance ensures longer lifespan.

(3d Printer Filament Machine 3d Printing Filament Extruder Plastic filament machine)