Discover a professional 3D printing powder supplier

PRODUCT PARAMETERS

Description

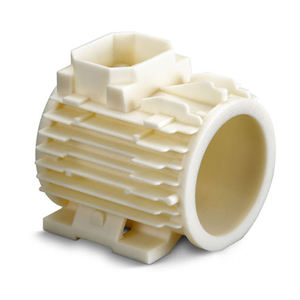

Overview of 3D printing 180 degrees automotive parts fast prototype HP printer 3D Print Plastic bobbinODM 3D printing products

3D printing, also known as additive manufacturing, is a transformative technology that allows the creation of three-dimensional objects by depositing materials layer by layer based on digital designs. This process opens up a new world of possibilities in product design, customization, and production, revolutionizing various industries including healthcare, aerospace, automotive, consumer goods, and more.

Customization & Personalization: One of the key advantages of 3D printing is its ability to create highly customized products tailored to individual needs or preferences, from prosthetics to fashion accessories.

Complex Geometry: 3D printing excels at producing intricate shapes and geometries that would be extremely challenging or impossible to manufacture using conventional methods, such as internal lattice structures or organic forms.

Rapid Prototyping: It significantly speeds up the product development cycle by enabling designers and engineers to quickly produce physical prototypes for testing and refinement.

On-Demand Manufacturing: The technology supports small-batch or even one-off production runs economically, reducing the need for large inventories and allowing for just-in-time manufacturing.

Material Diversity: A wide range of materials can be used in 3D printing, including plastics, metals, ceramics, composites, and even biomaterials, each offering unique properties for specific applications.

Reduced Waste: As compared to subtractive manufacturing techniques, 3D printing only adds material where needed, leading to less waste and a more sustainable manufacturing process.

Features of 3D printing 180 degrees automotive parts fast prototype HP printer 3D Print Plastic bobbinODM 3D printing products

Design Flexibility: The technology enables the realization of complex designs without the constraints of traditional manufacturing tools and molds.

Functional Integration: Parts can be designed with integrated features such as channels, cavities, or interlocking components, which can enhance functionality or simplify assembly.

Lightweight Structures: Advanced 3D printing techniques allow for the creation of lightweight yet strong structures through optimized designs and the use of lattice structures or composite materials.

Improved Performance: By precisely controlling material composition and structure, 3D printed parts can exhibit enhanced mechanical, thermal, or electrical properties.

Cost-Efficiency for Complexity: While 3D printing may not always compete with mass-production methods for simple parts, it becomes increasingly cost-effective as the complexity of the part increases.

Innovative Applications: From medical implants that match a patient’s anatomy perfectly to aerospace components that reduce weight and increase efficiency, 3D printing pushes the boundaries of what’s possible in product design and engineering.

(3D printing 180 degrees automotive parts fast prototype HP printer 3D Print Plastic bobbinODM 3D printing products)

Specification of 3D printing 180 degrees automotive parts fast prototype HP printer 3D Print Plastic bobbinODM 3D printing products

This service gives fast 3D published prototypes for automobile parts. We concentrate on producing practical designs swiftly. Rate is vital in automotive advancement. Our process utilizes innovative HP Multi Jet Combination technology. This approach constructs parts layer by layer precisely. It’s much faster than conventional machining. You obtain parts in days, not weeks.

We concentrate on complicated vehicle components. These include parts requiring 180-degree rotation or complex geometries. Plastic bobbins are a key instance. Our HP printers manage these forms well. They create strong, exact plastic parts. The product simulates final manufacturing plastics. This allows for sensible testing and installation.

Our group manages the entire prototype process. We are an ODM partner. This means we style and manufacture based on your needs. You supply the idea or fundamental demands. We take care of the CAD modeling, printing, and ending up. We use industrial-grade nylon plastics. These materials are long lasting. They stand up to warmth and stress and anxiety like actual automotive parts.

The main advantage is fast turn-around. Testing designs swiftly increases advancement. Finding problems very early saves time and money. Layout modifications are straightforward to execute. Just upgrade the electronic documents. Publish the modified part quick. This adaptability is crucial for fulfilling limited target dates. Modification is easy too. Each model is produced your particular application. Tiny batches are no problem. We support low-volume first manufacturing runs. This connects the gap between prototype and full production.

Our HP 3D printers deliver high information and smooth surfaces. Parts require very little post-processing. They await practical checks or assembly tests. Strength and dimensional accuracy fulfill auto criteria. This makes certain prototypes do accurately under test conditions. We aid you confirm designs before committing to pricey tooling.

(3D printing 180 degrees automotive parts fast prototype HP printer 3D Print Plastic bobbinODM 3D printing products)

Applications of 3D printing 180 degrees automotive parts fast prototype HP printer 3D Print Plastic bobbinODM 3D printing products

Making vehicle components utilized to take weeks or months. Waiting slowed everything down. Now, HP’s 3D printers transform that. They construct solid plastic models unbelievably quick. Believe 180 degrees turn-around for complicated components. This rate is a large offer for vehicle makers.

Required a brand-new brace, duct, or indoor piece quickly? This HP system prints it straight from your layout documents. Fail to remember waiting on costly tooling. You obtain a physical component in your hands promptly. Examine exactly how it fits. Evaluate how it functions. Make changes quickly if needed. This conserves significant quantities of time and cash throughout growth.

The printers use special plastic product on bobbins. This material is tough. It handles warmth and stress and anxiety well, like actual car components. Printing layer by layer produces accurate, thorough versions. You see specifically how the last manufacturing component will feel and look. Designers and developers love this prompt comments.

Beyond prototypes, this is terrific for customized tools and fixtures on the assembly line. Need a special wrench or jig? Publish it over night. It obtains production moving once again immediately.

We also supply ODM services. Have an idea for a specific 3D printed component? We assist design it. We assist produce it making use of these fast HP printers. This offers you adaptability. Obtain custom remedies without huge investments in machines.

Company Profile

3D Printing Passion is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality 3D printing powder and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality 3D printing materials and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of 3D printing 180 degrees automotive parts fast prototype HP printer 3D Print Plastic bobbinODM 3D printing products

Here are five common questions about our 3D printed automotive prototype parts using HP printers:

People ask what materials we use. We use strong plastic bobbins. These plastics work well for car part models. They handle heat and stress okay. We pick the best plastic for each job.

Everyone wants speed. Our HP printers are very fast. They build layers quickly. You get your prototype part much sooner. Fast printing means faster testing and changes.

Accuracy matters a lot. HP printers are precise. They make parts very close to your design files. This is good for checking fit and function. You see problems early.

People worry if the parts are strong enough. These are prototypes, not final parts. The plastic is strong enough for testing. You can handle and assemble them. They show how the real part will work.

Many need custom parts. We make exactly what you design. We print unique shapes and features. This is great for special car parts. You test your specific idea quickly.

Our service uses HP Multi Jet Fusion technology. We focus on quick turnaround for automotive prototypes. We help you develop parts faster.

(3D printing 180 degrees automotive parts fast prototype HP printer 3D Print Plastic bobbinODM 3D printing products)