Discover a professional 3D printing powder supplier

PRODUCT PARAMETERS

Description

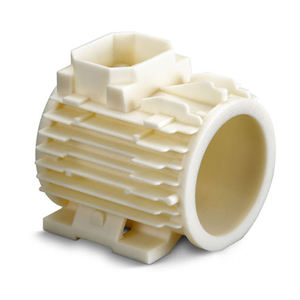

Overview of 3D Printing CNC Rapid Prototype Services

3D printing, also known as additive manufacturing, is a transformative technology that allows the creation of three-dimensional objects by depositing materials layer by layer based on digital designs. This process opens up a new world of possibilities in product design, customization, and production, revolutionizing various industries including healthcare, aerospace, automotive, consumer goods, and more.

Customization & Personalization: One of the key advantages of 3D printing is its ability to create highly customized products tailored to individual needs or preferences, from prosthetics to fashion accessories.

Complex Geometry: 3D printing excels at producing intricate shapes and geometries that would be extremely challenging or impossible to manufacture using conventional methods, such as internal lattice structures or organic forms.

Rapid Prototyping: It significantly speeds up the product development cycle by enabling designers and engineers to quickly produce physical prototypes for testing and refinement.

On-Demand Manufacturing: The technology supports small-batch or even one-off production runs economically, reducing the need for large inventories and allowing for just-in-time manufacturing.

Material Diversity: A wide range of materials can be used in 3D printing, including plastics, metals, ceramics, composites, and even biomaterials, each offering unique properties for specific applications.

Reduced Waste: As compared to subtractive manufacturing techniques, 3D printing only adds material where needed, leading to less waste and a more sustainable manufacturing process.

Features of 3D Printing CNC Rapid Prototype Services

Design Flexibility: The technology enables the realization of complex designs without the constraints of traditional manufacturing tools and molds.

Functional Integration: Parts can be designed with integrated features such as channels, cavities, or interlocking components, which can enhance functionality or simplify assembly.

Lightweight Structures: Advanced 3D printing techniques allow for the creation of lightweight yet strong structures through optimized designs and the use of lattice structures or composite materials.

Improved Performance: By precisely controlling material composition and structure, 3D printed parts can exhibit enhanced mechanical, thermal, or electrical properties.

Cost-Efficiency for Complexity: While 3D printing may not always compete with mass-production methods for simple parts, it becomes increasingly cost-effective as the complexity of the part increases.

Innovative Applications: From medical implants that match a patient’s anatomy perfectly to aerospace components that reduce weight and increase efficiency, 3D printing pushes the boundaries of what’s possible in product design and engineering.

(3D Printing CNC Rapid Prototype Services )

Specification of 3D Printing CNC Rapid Prototype Services

Our 3D Printing and CNC Rapid Prototype Solutions deliver specific, effective solutions for product growth. The services cover a variety of materials. 3D printing supports plastics like ABS, PLA, nylon, and resins. Steel options include stainless-steel, light weight aluminum, titanium, and copper alloys. CNC machining handles metals such as light weight aluminum, steel, brass, and titanium. Design plastics like PEEK, Delrin, and polycarbonate are also compatible. Both methods ensure high accuracy. 3D printing achieves layer resolutions approximately 0.1 mm. CNC machining preserves tolerances within 0.05 mm for complicated geometries.

Manufacturing speed varies based on project requirements. 3D printing produces parts within hours or days. CNC machining takes longer for multi-axis operations. 3D printing suits quick prototyping. CNC machining works much better for high-strength, end-use parts. Both solutions support low-volume manufacturing. Industries like automotive, aerospace, clinical, and consumer electronic devices advantage. Applications consist of functional models, personalized tools, real estates, and mechanical components.

Style versatility is a concern. 3D printing takes care of elaborate forms and inner structures. CNC machining provides smooth surfaces and precise sides. Files accepted include action, IGES, STL, and X_T. Our group assesses styles for manufacturability. Changes are suggested to decrease costs or enhance performance.

Surface area ending up choices add convenience. 3D-printed components can be fined sand, painted, or electroplated. CNC-machined parts sustain polishing, anodizing, or powder finishing. Personalized packaging and labeling are offered for branding.

Expense depends upon product option, part size, and production quantity. 3D printing lowers costs for intricate designs. CNC machining provides better rates for metal bulk orders. Lead times start at 24 hr for 3D printing. CNC projects typically call for 3-5 days. Thrill solutions are offered.

Quality control includes dimensional checks and product qualifications. Every component undertakes assessment before delivery. Technical assistance covers design optimization and material selection. Worldwide shipping alternatives ensure fast delivery.

Custom-made requests rate. Projects needing crossbreed manufacturing or one-of-a-kind products are managed case by case. Samples can be offered evaluation. Style data are kept personal. Revisions are cost-free during the estimating phase.

These services enhance product growth from idea to manufacturing. Iterations are faster. Costs remain convenient. Performance screening is much easier with physical prototypes. Risk of errors drops dramatically.

(3D Printing CNC Rapid Prototype Services )

Applications of 3D Printing CNC Rapid Prototype Services

3D printing and CNC fast prototype services alter just how industries develop products. These technologies produce precise physical versions from electronic styles. They speed up the procedure of screening concepts prior to complete production. Firms save time and money by dealing with style flaws early.

The automotive industry utilizes these services greatly. Designers examination components like engine parts or custom-made fixtures. They examine resilience and fit without awaiting standard manufacturing. This decreases hold-ups in lorry advancement. Aerospace firms profit also. They make lightweight yet solid parts for airplane. Complicated forms that are difficult to machine traditionally end up being feasible with 3D printing. Custom devices for production line are also generated much faster.

Clinical areas rely on these modern technologies for patient-specific options. Surgeons method on 3D-printed versions of body organs prior to procedures. Prosthetics and implants are customized to individual makeup. Oral labs create crowns and bridges rapidly. Biocompatible products guarantee security in these applications.

Customer electronics brands use prototypes to improve item layouts. They examine exactly how switches really feel or just how components snap together. Functional prototypes let users connect with tools early. Feedback enhances the end product. Small companies utilize these services to take on larger business. They launch products faster without big upfront expenses.

Education and learning and study industries adopt 3D printing and CNC for hands-on learning. Pupils research engineering concepts by developing genuine versions. Researchers develop prototypes for experiments or brand-new developments. Custom-made lab devices is made as needed.

Customized manufacturing is one more crucial location. Low-volume manufacturing runs suit particular niche markets. Business offer individualized items without mass-production configurations. Musicians and developers turn digital art right into physical objects.

These services support fast development throughout fields. They link the space in between concepts and real-world services. Organizations adapt to market needs quicker. Waste goes down as materials are made use of efficiently. Errors are captured prior to they become pricey. The adaptability of 3D printing and CNC machining meets diverse industry demands.

Company Profile

3D Printing Passion is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality 3D printing powder and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality 3D printing materials and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of 3D Printing CNC Rapid Prototype Services

What is 3D printing rapid prototyping?

3D printing builds parts layer by layer using materials like plastic or resin. It is ideal for creating complex shapes quickly. This method suits early-stage prototypes or small batches. It reduces waste compared to traditional methods.

How does CNC prototyping differ from 3D printing?

CNC machining cuts material from a solid block using tools like drills or mills. It works best for metals or tough plastics needing high precision. CNC is slower for complex designs but stronger for final products.

What materials can be used in these services?

3D printing commonly uses plastics, resins, or nylon. CNC handles metals like aluminum, steel, or titanium. Both methods support custom material choices based on project needs. Material selection affects durability, cost, and finish.

How long does rapid prototyping take?

Turnaround depends on design complexity and quantity. Simple 3D prints take hours. CNC parts might need days for setup and machining. Rush services are available. Timelines are confirmed after design review.

What are the costs of these services?

Costs vary with material type, part size, and production volume. 3D printing is cheaper for small batches. CNC costs more for machine time and material waste. Quotes are provided after analyzing design files.

(3D Printing CNC Rapid Prototype Services )