Discover a professional 3D printing powder supplier

PRODUCT PARAMETERS

Description

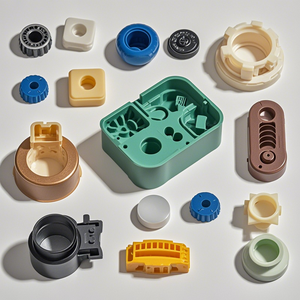

Overview of 3D printing FDM process service PLA four color product multi-color little lion

3D printing, also known as additive manufacturing, is a transformative technology that allows the creation of three-dimensional objects by depositing materials layer by layer based on digital designs. This process opens up a new world of possibilities in product design, customization, and production, revolutionizing various industries including healthcare, aerospace, automotive, consumer goods, and more.

Customization & Personalization: One of the key advantages of 3D printing is its ability to create highly customized products tailored to individual needs or preferences, from prosthetics to fashion accessories.

Complex Geometry: 3D printing excels at producing intricate shapes and geometries that would be extremely challenging or impossible to manufacture using conventional methods, such as internal lattice structures or organic forms.

Rapid Prototyping: It significantly speeds up the product development cycle by enabling designers and engineers to quickly produce physical prototypes for testing and refinement.

On-Demand Manufacturing: The technology supports small-batch or even one-off production runs economically, reducing the need for large inventories and allowing for just-in-time manufacturing.

Material Diversity: A wide range of materials can be used in 3D printing, including plastics, metals, ceramics, composites, and even biomaterials, each offering unique properties for specific applications.

Reduced Waste: As compared to subtractive manufacturing techniques, 3D printing only adds material where needed, leading to less waste and a more sustainable manufacturing process.

Features of 3D printing FDM process service PLA four color product multi-color little lion

Design Flexibility: The technology enables the realization of complex designs without the constraints of traditional manufacturing tools and molds.

Functional Integration: Parts can be designed with integrated features such as channels, cavities, or interlocking components, which can enhance functionality or simplify assembly.

Lightweight Structures: Advanced 3D printing techniques allow for the creation of lightweight yet strong structures through optimized designs and the use of lattice structures or composite materials.

Improved Performance: By precisely controlling material composition and structure, 3D printed parts can exhibit enhanced mechanical, thermal, or electrical properties.

Cost-Efficiency for Complexity: While 3D printing may not always compete with mass-production methods for simple parts, it becomes increasingly cost-effective as the complexity of the part increases.

Innovative Applications: From medical implants that match a patient’s anatomy perfectly to aerospace components that reduce weight and increase efficiency, 3D printing pushes the boundaries of what’s possible in product design and engineering.

(3D printing FDM process service PLA four color product multi-color little lion)

Specification of 3D printing FDM process service PLA four color product multi-color little lion

This 3D printing solution utilizes FDM innovation to create multi-color PLA products like the little lion design. The FDM process develops items layer by layer. It melts PLA filament and deposits it precisely. PLA is a popular material. It is green and made from renewable energies. The material is safe for interior use. It has reduced warping and sticks well during printing. The little lion version comes in 4 shades. Colors are used during printing. No painting or post-processing is needed. The printer switches over filaments automatically at particular layers. This creates clean shade transitions. Custom color combinations are offered. Clients select shades from a pre-programmed palette. The published lion has smooth surface areas. Details like the hair and facial attributes are sharp. Layer lines are marginal. The model is long lasting. It works as a decorative item or plaything. Sizes range from 5cm to 20cm in elevation. Larger dimensions keep details intact. The solution accepts custom-made demands. Customers give dimensions or readjust existing styles. Printing time depends on size. Tiny lions take 3-5 hours. Larger ones take 10-12 hours. Orders ship within 3 company days. Models are readily available for approval. Alterations are permitted before final production. PLA is naturally degradable. It suits eco-conscious projects. The material is light-weight. It resists moisture better than various other plastics. Colors remain vibrant in time. Direct sunshine direct exposure is not advised. The service targets enthusiasts, instructors, and services. Institutions utilize the lions for STEM jobs. Stores market them as souvenirs. Developers examination principles with physical models. Files should remain in STL or OBJ format. The group checks files for printability. Assistance structures are included if needed. These are eliminated after printing. No rough sides remain. Clients obtain tracking details after shipping. Mass orders get marked down rates. Sample lions are available for top quality checks.

(3D printing FDM process service PLA four color product multi-color little lion)

Applications of 3D printing FDM process service PLA four color product multi-color little lion

The FDM 3D printing process utilizing PLA product provides a sensible option for creating multi-color products like the four-color little lion version. This solution is excellent for generating in-depth, vivid designs with accuracy. PLA, a naturally degradable plastic derived from renewable resources, guarantees eco-friendly production. The layer-by-layer strategy in FDM printing enables complicated shapes and appearances to be constructed effectively. The four-color ability includes visual charm without needing hands-on painting.

This technology matches small manufacturing and custom projects. The little lion design acts as a decorative product, academic device, or marketing item. Institutions use it to educate 3D printing essentials. Businesses order branded versions for events. Enthusiasts take pleasure in individualizing styles. The process supports rapid prototyping, making it possible for quick adjustments to size or features.

Longevity is a key advantage. PLA withstands wear and maintains form under regular conditions. The little lion model withstands handling without fading. Multi-color printing integrates colors straight into the material. This removes post-processing steps like paint. Manufacturing time remains brief. Costs remain reduced for tiny batches or single items.

Customization options are versatile. Clients choose shades, dimensions, or small design tweaks. Data are sent digitally. Prints are shipped all set to make use of. The solution helps both basic and intricate versions. The little lion’s mane, facial features, and pose highlight the accuracy of FDM. Thin layers produce smooth surface areas. Sharp details remain intact.

Industries like retail, education, and advertising advantage. Stores show the lion as captivating decor. Educators demonstrate engineering principles. Business distribute miniatures as souvenirs. Artists prototype sculptures. Home individuals print playthings or presents. The procedure adapts to diverse needs.

PLA’s reduced melting point decreases energy usage. Printing temperatures are safer. Odors are very little. Offices stay comfortable. Waste material is recyclable. Fell short prints can be reprocessed. Ecological effect stays low.

The four-color system makes use of specialized extruders. Each shade loads individually. Transitions between tones are tidy. Color bleeding is uncommon. The final product appears brightened. Handbook touch-ups are unnecessary. Consistency across sets is dependable.

Cost-effectiveness makes the solution obtainable. No mold and mildews or tools are needed. Design modifications sustain minimal fees. Small orders are possible. Turnaround times range from hours to days. Immediate demands are accommodated. Global delivery is offered.

The little lion model exhibits the capacity of multi-color FDM printing. Its mix of aesthetic appeals and capability satisfies numerous demands. Individuals obtain a versatile product without endangering top quality.

Company Profile

3D Printing Passion is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality 3D printing powder and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality 3D printing materials and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of 3D printing FDM process service PLA four color product multi-color little lion

1. What is the FDM process used for 3D printing the multi-color lion? The FDM process builds the lion layer by layer using melted PLA plastic. A nozzle heats the PLA filament and deposits it precisely to form the shape. PLA is chosen because it is eco-friendly, easy to use, and creates smooth details. This method ensures the lion’s complex design and multiple colors are accurately captured.

2. How are four colors applied to the lion during printing? The printer switches between four PLA filament colors automatically. Each color is loaded into a separate nozzle or changed by the machine during pauses. The layers are printed in a specific order to blend colors without manual painting. This technology ensures clean transitions between colors.

3. Is the PLA material durable for long-term use? PLA is strong and holds details well but has limits. It resists wear and stays stable under normal conditions. Avoid leaving it in direct sunlight or high heat. PLA works best for decorative items like the lion. For heavy use, other materials might be better.

4. Can I request custom colors or design changes for the lion? Yes. Color combinations can be adjusted before printing. Small design tweaks are possible but depend on the model’s complexity. Share your ideas with the service team to check feasibility. Major changes might need extra costs or time.

5. How long does printing and shipping take? Printing time varies by size and detail. A small lion takes 2-3 hours. Larger versions take up to a day. Shipping starts after quality checks. Delivery times depend on location. Standard shipping usually takes 3-7 business days. Rush options are available for faster needs.

(3D printing FDM process service PLA four color product multi-color little lion)