Discover a professional 3D printing powder supplier

PRODUCT PARAMETERS

Description

Overview of 3D Printing Made by Stainless Steel

3D printing, also known as additive manufacturing, is a transformative technology that allows the creation of three-dimensional objects by depositing materials layer by layer based on digital designs. This process opens up a new world of possibilities in product design, customization, and production, revolutionizing various industries including healthcare, aerospace, automotive, consumer goods, and more.

Customization & Personalization: One of the key advantages of 3D printing is its ability to create highly customized products tailored to individual needs or preferences, from prosthetics to fashion accessories.

Complex Geometry: 3D printing excels at producing intricate shapes and geometries that would be extremely challenging or impossible to manufacture using conventional methods, such as internal lattice structures or organic forms.

Rapid Prototyping: It significantly speeds up the product development cycle by enabling designers and engineers to quickly produce physical prototypes for testing and refinement.

On-Demand Manufacturing: The technology supports small-batch or even one-off production runs economically, reducing the need for large inventories and allowing for just-in-time manufacturing.

Material Diversity: A wide range of materials can be used in 3D printing, including plastics, metals, ceramics, composites, and even biomaterials, each offering unique properties for specific applications.

Reduced Waste: As compared to subtractive manufacturing techniques, 3D printing only adds material where needed, leading to less waste and a more sustainable manufacturing process.

Features of 3D Printing Made by Stainless Steel

Design Flexibility: The technology enables the realization of complex designs without the constraints of traditional manufacturing tools and molds.

Functional Integration: Parts can be designed with integrated features such as channels, cavities, or interlocking components, which can enhance functionality or simplify assembly.

Lightweight Structures: Advanced 3D printing techniques allow for the creation of lightweight yet strong structures through optimized designs and the use of lattice structures or composite materials.

Improved Performance: By precisely controlling material composition and structure, 3D printed parts can exhibit enhanced mechanical, thermal, or electrical properties.

Cost-Efficiency for Complexity: While 3D printing may not always compete with mass-production methods for simple parts, it becomes increasingly cost-effective as the complexity of the part increases.

Innovative Applications: From medical implants that match a patient’s anatomy perfectly to aerospace components that reduce weight and increase efficiency, 3D printing pushes the boundaries of what’s possible in product design and engineering.

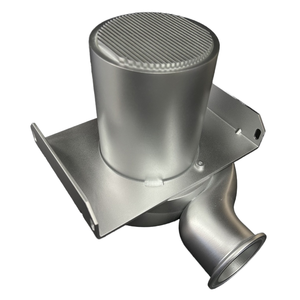

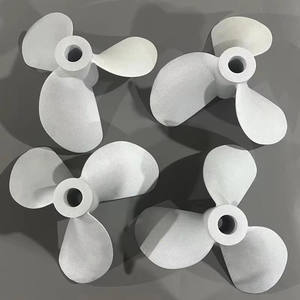

(3D Printing Made by Stainless Steel)

Specification of 3D Printing Made by Stainless Steel

Stainless-steel 3D printing produces solid, sturdy steel components. The product is primarily 316L stainless steel. This type offers exceptional deterioration resistance. It handles challenging atmospheres well, like chemicals or seawater.

Printed parts attain excellent detail. Regular feature resolution is around 0.2 mm. This indicates little details come out plainly. Wall surface thickness can be extremely slim. Minimum walls are frequently concerning 0.4 mm. This permits complex, lightweight designs.

Surface area finish is harsh right off the printer. Anticipate a rough appearance. Think fine sandpaper. This roughness is normal. Post-processing is normally required for a smooth appearance. Usual approaches consist of sandblasting, brightening, or machining. These actions improve the look and feel.

The mechanical residential properties are strong. Printed stainless-steel components are hard. They resist put on effectively. Tensile strength is high, comparable to commonly made components. This means they take care of pulling forces well. Yield strength is also great. Parts flex less under pressure.

Dimensional precision is reliable. Components normally match the electronic version carefully. Resistances are typically within ± 0.1 mm per 25 mm of component dimension. Small features might have slightly broader tolerances. It relies on the part geometry and printing direction.

Assistance frameworks are necessary during printing. They hold looming features. Getting rid of these supports leaves marks. These marks require tidying up afterward. The quantity of assistance influences post-processing time and price. Layout selections can reduce assistance requirements.

Warmth treatment is commonly used. This alleviates inner stresses from the printing process. It makes the parts a lot more secure. Heat therapy can additionally slightly change material buildings. This action guarantees long-lasting efficiency.

The technology helps models and end products. It fits intricate shapes difficult to make otherwise. Applications include functional elements, medical devices, and custom-made fixtures. Stainless steel 3D printing supplies design freedom with steel strength.

(3D Printing Made by Stainless Steel)

Applications of 3D Printing Made by Stainless Steel

Stainless steel 3D printing makes really solid, detailed metal components. This technology transforms exactly how industries make things. Aerospace business utilize it a lot. They publish solid jet engine parts and custom brackets. These parts manage high heat and pressure well. They are additionally lighter than old manufacturing techniques. This saves fuel.

Medical devices profit considerably. Surgeons use stainless steel 3D printed instruments. These devices are exact and withstand rust. Health centers require this for sanitation. Custom implants for bones are possible also. The product is safe inside the human body. It lasts a long time.

Factories count on durable tools. Stainless-steel 3D printing creates jigs and components fast. These tools hold components throughout setting up. Assembly line maintain moving. Changing damaged maker components is quicker. Manufacturing facilities stay clear of lengthy waits for replacements. They take care of tools faster.

Auto manufacturers utilize this technology. They test new engine layouts utilizing published parts. Prototypes are ready earlier. Customized components for high-performance cars and trucks are made. Small batches are inexpensive. Facility shapes are no problem. Traditional approaches deal with these shapes.

Even daily things utilize it. Solid, custom jewelry is printed in stainless steel. One-of-a-kind home fixtures and kitchen area devices are made. Designers produce intricate art items. The material looks excellent and lasts.

The procedure constructs objects layer by layer from steel powder. A laser melts the powder specifically. This allows detailed designs. Interior channels and lightweight frameworks are easy. Old approaches can refrain from doing this easily. Waste product is decreased dramatically. Only needed powder is utilized. This conserves money and product. Stainless-steel 3D printing offers new layout freedom. Production speed boosts. Prices for complicated components decrease.

Company Profile

3D Printing Passion is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality 3D printing powder and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality 3D printing materials and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of 3D Printing Made by Stainless Steel

What makes stainless steel good for 3D printing?

Stainless steel resists rust well. It handles tough conditions. 3D printing builds complex shapes easily. Traditional methods struggle with these shapes. Stainless steel combines strength and design freedom. This is useful for many industries.

Is 3D printed stainless steel as strong as regular stainless steel?

Yes, it can be very strong. The final strength depends on the printing method. Post-processing like heat treatment is often needed. This step makes the metal denser and stronger. Done right, printed parts match or get close to forged metal strength.

What things are usually made with stainless steel 3D printing?

People make parts needing strength and corrosion resistance. Examples include custom machine components. Another example is tough tools and jigs. Medical implants and surgical tools use it too. Complex fluid system parts are common. Aerospace and automotive prototypes use it often.

What specific stainless steel types are used?

316L stainless steel is the most common choice. It offers excellent corrosion resistance. It’s also good for many applications. 17-4 PH stainless steel is another option. It can be heat treated for higher strength. The choice depends on what the part needs to do.

How accurate is stainless steel 3D printing?

It’s generally very precise. Modern metal printers achieve fine details. Tolerances are often around +/- 0.1 mm. But accuracy depends on the part design. The printing process matters too. Support structures used during printing can affect the surface. Post-processing might add small changes.

(3D Printing Made by Stainless Steel)