Discover a professional 3D printing powder supplier

PRODUCT PARAMETERS

Description

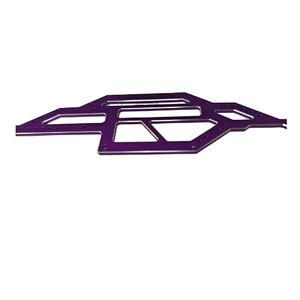

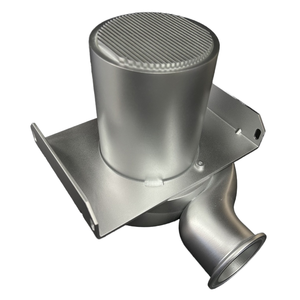

Overview of Custom 3D Printing Service Cnc Model STL files 3D Design Nylon12 SLS PA12 3D Printing Made In

3D printing, also known as additive manufacturing, is a transformative technology that allows the creation of three-dimensional objects by depositing materials layer by layer based on digital designs. This process opens up a new world of possibilities in product design, customization, and production, revolutionizing various industries including healthcare, aerospace, automotive, consumer goods, and more.

Customization & Personalization: One of the key advantages of 3D printing is its ability to create highly customized products tailored to individual needs or preferences, from prosthetics to fashion accessories.

Complex Geometry: 3D printing excels at producing intricate shapes and geometries that would be extremely challenging or impossible to manufacture using conventional methods, such as internal lattice structures or organic forms.

Rapid Prototyping: It significantly speeds up the product development cycle by enabling designers and engineers to quickly produce physical prototypes for testing and refinement.

On-Demand Manufacturing: The technology supports small-batch or even one-off production runs economically, reducing the need for large inventories and allowing for just-in-time manufacturing.

Material Diversity: A wide range of materials can be used in 3D printing, including plastics, metals, ceramics, composites, and even biomaterials, each offering unique properties for specific applications.

Reduced Waste: As compared to subtractive manufacturing techniques, 3D printing only adds material where needed, leading to less waste and a more sustainable manufacturing process.

Features of Custom 3D Printing Service Cnc Model STL files 3D Design Nylon12 SLS PA12 3D Printing Made In

Design Flexibility: The technology enables the realization of complex designs without the constraints of traditional manufacturing tools and molds.

Functional Integration: Parts can be designed with integrated features such as channels, cavities, or interlocking components, which can enhance functionality or simplify assembly.

Lightweight Structures: Advanced 3D printing techniques allow for the creation of lightweight yet strong structures through optimized designs and the use of lattice structures or composite materials.

Improved Performance: By precisely controlling material composition and structure, 3D printed parts can exhibit enhanced mechanical, thermal, or electrical properties.

Cost-Efficiency for Complexity: While 3D printing may not always compete with mass-production methods for simple parts, it becomes increasingly cost-effective as the complexity of the part increases.

Innovative Applications: From medical implants that match a patient’s anatomy perfectly to aerospace components that reduce weight and increase efficiency, 3D printing pushes the boundaries of what’s possible in product design and engineering.

(Custom 3D Printing Service Cnc Model STL files 3D Design Nylon12 SLS PA12 3D Printing Made In)

Specification of Custom 3D Printing Service Cnc Model STL files 3D Design Nylon12 SLS PA12 3D Printing Made In

Custom 3D Printing Solution supplies accuracy production for intricate components utilizing innovative SLS technology. The product made use of is Nylon12 (PA12), a resilient nylon powder ideal for useful prototypes and end-use components. This material provides high stamina, flexibility, and resistance to wear, chemicals, and warm. Parts made with PA12 are lightweight yet tough, appropriate for demanding applications throughout markets.

Customers have to provide 3D models in STL data style. The data need accurate geometry and correct wall thickness to ensure print success. Minimum wall surface thickness should be 1mm for security. Layouts with slim sections or in need of support frameworks may require modifications to avoid bending. Our group checks each declare errors and suggests fixes if needed.

SLS printing constructs parts layer by layer utilizing a laser to fuse nylon powder. This process enables detailed styles without support structures, conserving material and time. The outcome is parts with smooth surfaces and fine details. Post-processing consists of bead blasting to eliminate excess powder and coloring for color uniformity. Added coatings like polishing or painting are offered on request.

This solution supports custom-made measure to 300mm x 300mm x 600mm. Tolerances range from ± 0.3% to ± 0.5%, relying on part geometry. Each order includes a design review to confirm specs suit demands. Preparations differ from 3 to 7 days, based upon part complexity and quantity.

Industries like aerospace, auto, clinical, and customer products make use of PA12 components for prototypes, jigs, real estates, and functional components. The product’s biocompatibility makes it risk-free for clinical gadgets. For automotive applications, it holds up against high temperatures in engine compartments.

Quality control checks every component for dimensional precision and stamina. Evaluating approaches consist of aesthetic evaluation, dimension with calipers, and stress tests if specified. Packaging utilizes protective products to avoid damage during delivery.

Made in centers with ISO-certified criteria, the service warranties consistency and integrity. Pricing depends on material quantity, print time, and post-processing choices. Customers get a quote after posting their STL documents.

(Custom 3D Printing Service Cnc Model STL files 3D Design Nylon12 SLS PA12 3D Printing Made In)

Applications of Custom 3D Printing Service Cnc Model STL files 3D Design Nylon12 SLS PA12 3D Printing Made In

Personalized 3D printing solutions using CNC model STL documents and Nylon12 SLS PA12 materials provide useful remedies for sectors needing specific and long lasting parts. These services turn electronic designs into physical things promptly. The procedure begins with developing a 3D version in STL file layout. This documents overviews printers to construct layer-by-layer parts with precision. Nylon12 SLS PA12 is a solid product. It manages warmth, chemicals, and put on well. This makes it perfect for useful models and end-use items.

Industries like automotive, aerospace, and clinical depend on these services. Designers utilize them to test layouts prior to mass production. Suppliers lower prices by avoiding costly molds. Custom parts fit particular demands without added tooling. Complicated shapes are very easy to publish. Standard methods have problem with detailed geometries. 3D printing streamlines this.

Medical areas take advantage of customized implants and medical devices. PA12’s biocompatibility fulfills safety and security standards. Automotive teams develop lightweight elements for much better fuel efficiency. Aerospace tasks make use of heat-resistant parts for engines. Consumer goods firms prototype products quicker. Adjustments to designs happen swiftly.

STL submits make sure compatibility throughout software program and equipment. Designers share data without style problems. SLS printing merges nylon powder with lasers. This creates solid frameworks with smooth surface areas. Parts need minimal post-processing. They await use after printing.

Nylon12 PA12 withstands oil and chemicals. It works in rough environments. Industrial equipment parts last much longer. Electrical parts stay insulated. Custom-made units safeguard devices from damage.

Small companies gain access to advanced manufacturing without large investments. Low-volume manufacturing runs end up being economical. Personalization supports niche markets. Designers experiment easily. No restrictions exist on shapes or appearances.

Standard production entails longer preparation. 3D printing delivers components in days. Layout mistakes obtain dealt with quick. Checking cycles shorten. Products reach markets earlier.

The mix of CNC models and SLS PA12 fulfills high requirements. Toughness and precision match vital applications. Adaptability in design modifications boosts technology. Industries conserve time and resources.

Medical gadgets fit patients perfectly. Automotive models match real-world problems. Aerospace parts endure extreme anxiety. Customer products obtain functional upgrades.

This technology sustains fast growth. It connects ideas and truth. Companies stay affordable with efficient options.

Company Profile

3D Printing Passion is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality 3D printing powder and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality 3D printing materials and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Custom 3D Printing Service Cnc Model STL files 3D Design Nylon12 SLS PA12 3D Printing Made In

Custom 3D Printing Service FAQs: CNC Model STL Files, 3D Design, Nylon12 SLS PA12

1. What materials are used for 3D printing?

We use Nylon12 (PA12) for SLS 3D printing. This material is strong, flexible, and heat-resistant. It works for functional parts, prototypes, and complex designs. Nylon12 suits industries like automotive, aerospace, and consumer products. The material is durable and lightweight.

2. Are there design rules for STL files?

Yes. Ensure STL files have a minimum wall thickness of 1mm. Avoid very thin features. Models must be watertight with no gaps or errors. Use standard resolution to prevent large file sizes. We check files before printing. Contact us for design guidelines if unsure.

3. How accurate are SLS-printed parts?

SLS printing offers high accuracy. Typical tolerances are ±0.3% (minimum ±0.3mm). Layer thickness is 0.1mm-0.15mm. Small details print clearly. Surface finishes are slightly grainy due to the SLS process. Post-processing like sanding or dyeing improves smoothness or color.

4. How long does production take?

Lead times depend on part size and order volume. Small orders ship in 3-5 days. Larger projects take 1-2 weeks. Design complexity and post-processing add time. We provide estimates after reviewing files. Rush services are available for urgent needs.

5. Can parts be customized?

Yes. We adjust material strength, color, and surface finish. Nylon12 parts are naturally white. Dyeing offers black, gray, or other colors. Coatings add textures or waterproofing. Custom engravings or logos are possible. Share requirements early for best results.

(Custom 3D Printing Service Cnc Model STL files 3D Design Nylon12 SLS PA12 3D Printing Made In)