Discover a professional 3D printing powder supplier

PRODUCT PARAMETERS

Description

Overview of Custom Rapid Prototype 3D Printing Service Cnc Machining Transparent Acrylic Part Plastic Protective Case

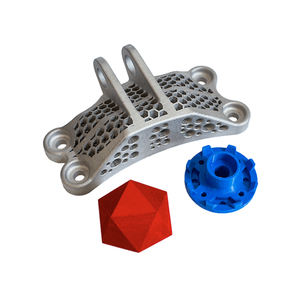

3D printing, also known as additive manufacturing, is a transformative technology that allows the creation of three-dimensional objects by depositing materials layer by layer based on digital designs. This process opens up a new world of possibilities in product design, customization, and production, revolutionizing various industries including healthcare, aerospace, automotive, consumer goods, and more.

Customization & Personalization: One of the key advantages of 3D printing is its ability to create highly customized products tailored to individual needs or preferences, from prosthetics to fashion accessories.

Complex Geometry: 3D printing excels at producing intricate shapes and geometries that would be extremely challenging or impossible to manufacture using conventional methods, such as internal lattice structures or organic forms.

Rapid Prototyping: It significantly speeds up the product development cycle by enabling designers and engineers to quickly produce physical prototypes for testing and refinement.

On-Demand Manufacturing: The technology supports small-batch or even one-off production runs economically, reducing the need for large inventories and allowing for just-in-time manufacturing.

Material Diversity: A wide range of materials can be used in 3D printing, including plastics, metals, ceramics, composites, and even biomaterials, each offering unique properties for specific applications.

Reduced Waste: As compared to subtractive manufacturing techniques, 3D printing only adds material where needed, leading to less waste and a more sustainable manufacturing process.

Features of Custom Rapid Prototype 3D Printing Service Cnc Machining Transparent Acrylic Part Plastic Protective Case

Design Flexibility: The technology enables the realization of complex designs without the constraints of traditional manufacturing tools and molds.

Functional Integration: Parts can be designed with integrated features such as channels, cavities, or interlocking components, which can enhance functionality or simplify assembly.

Lightweight Structures: Advanced 3D printing techniques allow for the creation of lightweight yet strong structures through optimized designs and the use of lattice structures or composite materials.

Improved Performance: By precisely controlling material composition and structure, 3D printed parts can exhibit enhanced mechanical, thermal, or electrical properties.

Cost-Efficiency for Complexity: While 3D printing may not always compete with mass-production methods for simple parts, it becomes increasingly cost-effective as the complexity of the part increases.

Innovative Applications: From medical implants that match a patient’s anatomy perfectly to aerospace components that reduce weight and increase efficiency, 3D printing pushes the boundaries of what’s possible in product design and engineering.

(Custom Rapid Prototype 3D Printing Service Cnc Machining Transparent Acrylic Part Plastic Protective Case)

Specification of Custom Rapid Prototype 3D Printing Service Cnc Machining Transparent Acrylic Part Plastic Protective Case

Required personalized plastic components made quickly? We provide quick prototype 3D printing and CNC machining services. Obtain transparent acrylic components, plastic safety situations, and other elements quickly. Rate issues when developing brand-new items. Our services deliver parts in days, not weeks.

3D printing develops components layer by layer directly from your electronic design. It’s outstanding for complex forms and fast design checks. You can test type and fit quickly. CNC machining cuts components exactly from solid plastic blocks. It’s much better for solid, resilient components requiring limited tolerances and smooth surfaces. Both methods benefit prototypes and little production runs.

Clear acrylic is a prominent choice. It resembles glass however is a lot harder. CNC machining acrylic provides optically clear parts with sharp edges. This is perfect for display home windows, lenses, or examination covers. You see clearly through the part. Acrylic resists scrapes and weather well.

Plastic safety situations shield important electronic devices or devices. We make personalized cases utilizing 3D printing or CNC machining. Your instance fits the product inside perfectly. Pick long lasting plastics like abdominal muscle or polycarbonate. These products take in shocks and safeguard against dust or water. Instances can have mounting points, seals, or particular appearances.

We take care of both simple and intricate designs. Send us your CAD file. We examine it for manufacturability. We choose the best procedure for your needs. You obtain a quote fast. Production starts swiftly after approval. Our devices run continuously. We prioritize fast turn-around. Quality checks make certain every part satisfies requirements. Parts ship straight to you.

(Custom Rapid Prototype 3D Printing Service Cnc Machining Transparent Acrylic Part Plastic Protective Case)

Applications of Custom Rapid Prototype 3D Printing Service Cnc Machining Transparent Acrylic Part Plastic Protective Case

Custom quick model 3D printing solution and CNC machining make new product ideas genuine quickly. You require components quickly for testing. These solutions deliver. They are best for explaining acrylic components and strong plastic protective instances.

Getting a model quick is important. It allows you evaluate your style early. You locate problems prior to large manufacturing. You conserve cash and time. Seeing your layout as a real things aids everybody understand it better. Adjustments are easy to make at this phase.

Clear acrylic is a terrific product for several uses. CNC machining cuts it specifically from strong blocks. The result is extremely clear, like glass, however a lot more powerful. It polishes well for an attractive coating. You see this in display stands, device guards, lighting fixtures, and evaluation home windows. Seeing within is essential.

Plastic safety cases maintain things secure. Model services make these instances rapidly. They fit electronic devices, tools, or clinical gadgets precisely. The material is difficult. It absorbs shocks and shields against dust and water. You check the situation with the actual item inside. You check the fit and the defense degree.

3D printing develops components layer by layer. It benefits intricate forms hard to device. CNC machining cuts product away. It offers a smoother surface and is much better for clear acrylic parts needing perfect quality. Both approaches benefit sturdy plastic cases. You pick the best one for your component’s demands.

Rate issues most in prototyping. These solutions transform your computer files into genuine parts in days, not weeks. You obtain examples to deal with and test. This quick comments loophole improves your item layout much faster. It decreases risk before you devote to pricey production tools.

Company Profile

3D Printing Passion is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality 3D printing powder and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality 3D printing materials and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Custom Rapid Prototype 3D Printing Service Cnc Machining Transparent Acrylic Part Plastic Protective Case

People often ask these questions about our custom acrylic and plastic prototype services. We make see-through acrylic parts and protective cases fast. You need answers quickly. Here are the top five things customers want to know.

What materials can you use for clear parts? We mainly use acrylic (PMMA) for perfect transparency. It looks like glass but is much stronger. We also use polycarbonate (PC) if you need even more impact resistance. PC is very tough but not quite as crystal clear as acrylic. Tell us your needs. We help pick the best material.

How fast can you make my prototype? Speed is our focus. We offer rapid CNC machining and 3D printing. Simple acrylic parts or plastic cases often ship in just 1-3 days. Complex designs might take 3-5 days. Send us your file. We give you a fast quote and exact timing.

Can you make the acrylic perfectly smooth and clear? Yes. Achieving optical clarity takes skill. We machine acrylic carefully. Then we polish it by hand or use special flame treatments. This removes tool marks. The result is a beautifully smooth, glass-like finish. We protect surfaces during shipping too.

Is transparent acrylic strong enough for protective cases? Absolutely. Machined acrylic is very durable. It resists impacts well. It protects sensitive electronics or parts effectively. For extreme conditions, polycarbonate is even stronger. Both materials make excellent shields. They keep things safe.

What file format should I send for my custom part? Send us your 3D CAD file. STEP or IGES files work best for CNC machining. STL files are good for 3D printing. Include your drawing if you have specific notes. We check everything. We confirm your design is ready before making it. Clear files prevent delays.

(Custom Rapid Prototype 3D Printing Service Cnc Machining Transparent Acrylic Part Plastic Protective Case)