Discover a professional 3D printing powder supplier

PRODUCT PARAMETERS

Description

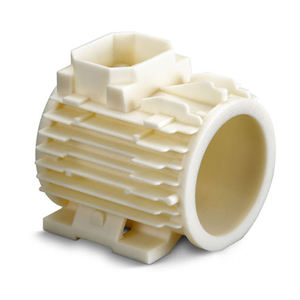

Overview of Custom resin 3d printing high-precision model 3d printing service fdm

3D printing, also known as additive manufacturing, is a transformative technology that allows the creation of three-dimensional objects by depositing materials layer by layer based on digital designs. This process opens up a new world of possibilities in product design, customization, and production, revolutionizing various industries including healthcare, aerospace, automotive, consumer goods, and more.

Customization & Personalization: One of the key advantages of 3D printing is its ability to create highly customized products tailored to individual needs or preferences, from prosthetics to fashion accessories.

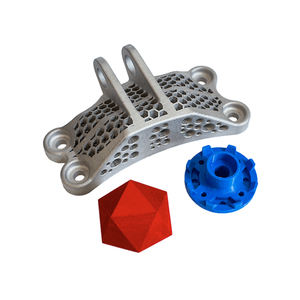

Complex Geometry: 3D printing excels at producing intricate shapes and geometries that would be extremely challenging or impossible to manufacture using conventional methods, such as internal lattice structures or organic forms.

Rapid Prototyping: It significantly speeds up the product development cycle by enabling designers and engineers to quickly produce physical prototypes for testing and refinement.

On-Demand Manufacturing: The technology supports small-batch or even one-off production runs economically, reducing the need for large inventories and allowing for just-in-time manufacturing.

Material Diversity: A wide range of materials can be used in 3D printing, including plastics, metals, ceramics, composites, and even biomaterials, each offering unique properties for specific applications.

Reduced Waste: As compared to subtractive manufacturing techniques, 3D printing only adds material where needed, leading to less waste and a more sustainable manufacturing process.

Features of Custom resin 3d printing high-precision model 3d printing service fdm

Design Flexibility: The technology enables the realization of complex designs without the constraints of traditional manufacturing tools and molds.

Functional Integration: Parts can be designed with integrated features such as channels, cavities, or interlocking components, which can enhance functionality or simplify assembly.

Lightweight Structures: Advanced 3D printing techniques allow for the creation of lightweight yet strong structures through optimized designs and the use of lattice structures or composite materials.

Improved Performance: By precisely controlling material composition and structure, 3D printed parts can exhibit enhanced mechanical, thermal, or electrical properties.

Cost-Efficiency for Complexity: While 3D printing may not always compete with mass-production methods for simple parts, it becomes increasingly cost-effective as the complexity of the part increases.

Innovative Applications: From medical implants that match a patient’s anatomy perfectly to aerospace components that reduce weight and increase efficiency, 3D printing pushes the boundaries of what’s possible in product design and engineering.

(Custom resin 3d printing high-precision model 3d printing service fdm)

Specification of Custom resin 3d printing high-precision model 3d printing service fdm

Resin 3D printing makes super detailed parts. It’s very different from FDM printing. FDM uses melted plastic filament. It builds things layer by layer. Resin printing uses liquid plastic cured by light. This method creates much smoother surfaces. You get finer details too. Tiny features come out sharp and clean. Resin printing is great for complex shapes. It handles delicate designs well.

We offer custom resin 3D printing services. You send us your 3D model file. We print it using high-precision resin printers. Our technology ensures excellent accuracy. Your model will look exactly like the digital design. The surface finish is smooth right off the printer. You won’t see obvious layer lines like on FDM parts. This saves time on sanding or finishing.

We use different types of resin. Standard resin works for most projects. It gives good detail and strength. Tough resin is stronger. It handles stress better. Flexible resin bends slightly. Clear resin is see-through. You choose the best material for your job. We help pick the right one if needed.

Getting parts is straightforward. Upload your file to our website. Our team checks it for printability. We add necessary supports automatically. These supports hold the model during printing. They get removed carefully after. Then we clean the part. We ship the finished model directly to you. High-quality custom parts arrive ready to use. This service is ideal for prototypes, miniatures, jewelry, and detailed components. FDM printing is good for larger, less detailed items. Resin printing wins for precision and fine features.

(Custom resin 3d printing high-precision model 3d printing service fdm)

Applications of Custom resin 3d printing high-precision model 3d printing service fdm

Resin 3D printing creates very detailed models. This method uses liquid plastic cured by light. It produces smooth surfaces and captures tiny features well. This makes it perfect for small, complex parts. Many industries use this high-precision service. Jewelry designers need it for intricate rings and pendants. Engineers use it for prototypes with fine details. Movie studios need it for small props and characters. Dentists use it for precise crowns and bridges. Architects use it for detailed building models. Hobbyists love it for painting miniature figures. The results look professional right off the printer. Little sanding is needed. Resin offers different types. Standard resin is good for general models. Tough resin handles parts needing some flex. Castable resin burns away cleanly for metal casting. Transparent resin makes clear parts like lenses. This service gives options for specific needs.

FDM 3D printing builds parts layer by layer. It uses melted plastic filament. FDM is strong and durable. It is good for functional prototypes. Designers test how parts move and fit together. It makes good jigs and fixtures for manufacturing. Companies use it for custom tool handles. FDM parts can handle stress and wear. This method uses plastics like ABS, PETG, and nylon. These materials resist heat and chemicals well. FDM parts are often stronger than resin parts. They are better for parts under load. FDM printers can make larger objects easily. The surface finish is rougher than resin. Sanding or painting improves the look. FDM is cost-effective for bigger pieces. It is reliable for end-use parts too. Both resin and FDM have important uses.

Company Profile

3D Printing Passion is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality 3D printing powder and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality 3D printing materials and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Custom resin 3d printing high-precision model 3d printing service fdm

Customers often ask about our custom resin 3D printing service. Here are the top five questions we get.

What materials do you offer for resin printing?

We use several types of liquid resin. We have standard resins for general models. We also have tough resins for durable parts. Flexible resins are available for bendable items. Clear resins let you see through the printed object. We choose the best material for your project.

How precise are resin prints compared to FDM?

Resin printing is very precise. It can create much finer details than FDM printing. Resin printers build layers much thinner. This means sharper edges and smoother curves. Tiny features come out clearly. FDM prints often show visible layer lines. Resin hides these lines better. It’s excellent for miniatures and complex designs.

What about the surface finish?

Resin prints have a smoother surface straight off the printer. They usually need less sanding or finishing work. The layer lines are almost invisible to the eye. You get a nicer feel right away. FDM parts often feel rougher. They require more effort to get smooth.

How fast is the turnaround time?

Resin printing itself is often faster per part than FDM for small, detailed items. Printing many small pieces at once speeds things up. Post-processing takes some time. We wash the parts to remove liquid resin. Then we cure them under UV light to harden completely. We work efficiently to deliver your order quickly.

Is resin printing more expensive?

Resin printing costs a bit more than FDM usually. The liquid resin material costs more than filament. The printing process itself uses more precise technology. Post-processing steps add to the total cost. You pay for the high detail and smooth finish. The price reflects the quality you receive.

(Custom resin 3d printing high-precision model 3d printing service fdm)