Discover a professional 3D printing powder supplier

PRODUCT PARAMETERS

Description

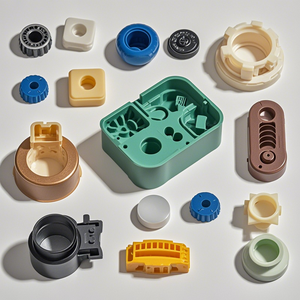

Overview of Customized Model High Quality Cnc Metal Rapid Prototype Plastic Sla Sls 3d Printing Service

3D printing, also known as additive manufacturing, is a transformative technology that allows the creation of three-dimensional objects by depositing materials layer by layer based on digital designs. This process opens up a new world of possibilities in product design, customization, and production, revolutionizing various industries including healthcare, aerospace, automotive, consumer goods, and more.

Customization & Personalization: One of the key advantages of 3D printing is its ability to create highly customized products tailored to individual needs or preferences, from prosthetics to fashion accessories.

Complex Geometry: 3D printing excels at producing intricate shapes and geometries that would be extremely challenging or impossible to manufacture using conventional methods, such as internal lattice structures or organic forms.

Rapid Prototyping: It significantly speeds up the product development cycle by enabling designers and engineers to quickly produce physical prototypes for testing and refinement.

On-Demand Manufacturing: The technology supports small-batch or even one-off production runs economically, reducing the need for large inventories and allowing for just-in-time manufacturing.

Material Diversity: A wide range of materials can be used in 3D printing, including plastics, metals, ceramics, composites, and even biomaterials, each offering unique properties for specific applications.

Reduced Waste: As compared to subtractive manufacturing techniques, 3D printing only adds material where needed, leading to less waste and a more sustainable manufacturing process.

Features of Customized Model High Quality Cnc Metal Rapid Prototype Plastic Sla Sls 3d Printing Service

Design Flexibility: The technology enables the realization of complex designs without the constraints of traditional manufacturing tools and molds.

Functional Integration: Parts can be designed with integrated features such as channels, cavities, or interlocking components, which can enhance functionality or simplify assembly.

Lightweight Structures: Advanced 3D printing techniques allow for the creation of lightweight yet strong structures through optimized designs and the use of lattice structures or composite materials.

Improved Performance: By precisely controlling material composition and structure, 3D printed parts can exhibit enhanced mechanical, thermal, or electrical properties.

Cost-Efficiency for Complexity: While 3D printing may not always compete with mass-production methods for simple parts, it becomes increasingly cost-effective as the complexity of the part increases.

Innovative Applications: From medical implants that match a patient’s anatomy perfectly to aerospace components that reduce weight and increase efficiency, 3D printing pushes the boundaries of what’s possible in product design and engineering.

(Customized Model High Quality Cnc Metal Rapid Prototype Plastic Sla Sls 3d Printing Service)

Specification of Customized Model High Quality Cnc Metal Rapid Prototype Plastic Sla Sls 3d Printing Service

Our firm gives top notch CNC steel and rapid prototyping services for customized parts. We specialize in CNC machining, SLA 3D printing, and SLS 3D printing to fulfill diverse commercial needs. Our services concentrate on accuracy, speed, and flexibility for both small-scale models and big manufacturing runs.

CNC steel machining utilizes innovative devices to produce components from materials like aluminum, steel, brass, and titanium. Tight resistances make certain accuracy within +/ -0.05 mm. This method matches practical models, personalized devices, and end-use parts. Quick turnaround times decrease delays in item growth.

Plastic rapid prototyping leverages SLA and SLS technologies. SLA generates smooth, comprehensive components using materials for applications requiring aesthetic clearness or penalty functions. SLS makes use of nylon powders for durable, heat-resistant parts without calling for support frameworks. Both approaches supply prototypes in 1-3 days, quickening testing and style modifications.

Material alternatives cover over 20 engineering-grade plastics and steels. Usual options consist of ABS, polycarbonate, stainless steel, and titanium. Custom product requests are supported for specific tasks. Surface surfaces vary from raw machined appearances to brightened, repainted, or anodized coverings.

Quality control is important. Each component goes through dimensional checks with CMM equipments and stress tests. Certifications like ISO 9001 assurance constant criteria. Style responses is used to optimize manufacturability and cost-efficiency.

Applications cover aerospace, automotive, clinical gadgets, and consumer electronic devices. Engineers use our solutions for functional testing, while services rely upon us for low-volume manufacturing. Worldwide delivery makes sure trustworthy distribution to clients worldwide.

Rates relies on material, dimension, and order quantity. Mass orders receive discounts. A specialized project management team takes care of queries 24/7. Data approved consist of STEP, STL, and IGES.

We focus on clear communication to line up outcomes with client expectations. Revisions are fit at any kind of stage. Preparations start at 24 hr for urgent tasks.

Our objective is to simplify custom production. Technical expertise and contemporary facilities make sure parts satisfy strenuous needs. We adapt process to fit distinct demands.

(Customized Model High Quality Cnc Metal Rapid Prototype Plastic Sla Sls 3d Printing Service)

Applications of Customized Model High Quality Cnc Metal Rapid Prototype Plastic Sla Sls 3d Printing Service

Customized design top notch CNC metal fast model plastic SLA SLS 3D printing services supply options for industries requiring specific and sturdy parts. These solutions combine advanced manufacturing methods to produce components quickly and accurately. CNC machining deals with steel parts with limited tolerances. Quick prototyping utilizes 3D printing to check designs fast. SHANTY TOWN (stereolithography) generates smooth plastic get rid of fine information. SLS (selective laser sintering) builds strong plastic or nylon components without support structures.

Industries like automobile rely upon these services. Personalized metal components for engines or brackets are made using CNC. Models for new vehicle styles are 3D published to check fit and function. This accelerates development and reduces expenses. Aerospace makes use of CNC-machined steel parts for high-strength applications. SLS-printed components stand up to severe temperatures and tension. Prototypes for airplane interiors are checked before final manufacturing.

Medical fields benefit from these services too. Surgical tools made through CNC guarantee accuracy. Customized implants are 3D published to match person makeup. Shanty town produces detailed models for pre-surgery preparation. Oral laboratories make use of SLS for sturdy crowns and bridges. This reduces wait times for patients.

Customer items make use of these innovations for rapid version. Plastic prototypes for electronic devices housings are made with shanty town. Steel parts for appliances are CNC-machined for sturdiness. SLS prints practical models for testing functional designs. Business launch products much faster by preventing standard tooling hold-ups.

Electronic devices makers use CNC for warmth sinks and connectors. 3D-printed plastic units safeguard circuits. Custom-made jigs and components streamline production line. SLA get rid of smooth surfaces are used for product display screens.

These services sustain tiny batches or massive production. Materials vary from steels like aluminum to engineering plastics. Quick turnaround times assist satisfy limited due dates. Expenses stay reduced by minimizing material waste and manual work. Designers obtain responses swiftly to refine products.

No industry is limited by complicated geometries or material requirements. Personalized services deal with distinct obstacles. High precision guarantees parts function as meant. Reliability makes these techniques crucial for contemporary production.

Company Profile

3D Printing Passion is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality 3D printing powder and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality 3D printing materials and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Customized Model High Quality Cnc Metal Rapid Prototype Plastic Sla Sls 3d Printing Service

What materials do you offer for prototypes? We provide metal and plastic options. Metals include aluminum, stainless steel, titanium. Plastics cover ABS, nylon, resin. Material choice depends on your project needs. Metals suit high-strength parts. Plastics work for detailed designs. We help pick the best fit based on function, cost, durability.

How does the process work? Share your design files with us. Our team checks for errors or improvements. We select the right method—CNC machining, SLA, or SLS printing. Production starts after approval. We update you at each stage. Final parts go through inspection before shipping.

Can you guarantee precision and quality? Yes. Our machines achieve tolerances up to 0.1mm. We use advanced equipment like multi-axis CNC mills and industrial 3D printers. Every part undergoes checks for dimensions, surface finish, strength. We follow strict quality standards. This ensures prototypes meet exact requirements.

How long does production take? Most orders ship in 1-5 days. Time depends on size, method, complexity. Simple 3D prints finish faster. Complex metal parts take longer. Rush services are available. Share your deadline early for quicker results.

What affects the cost? Key factors include material type, part size, production method, order quantity. CNC machining costs more for hard metals. 3D printing saves money on intricate plastic parts. Larger orders often lower per-unit prices. We give free quotes after reviewing your design.

(Customized Model High Quality Cnc Metal Rapid Prototype Plastic Sla Sls 3d Printing Service)