Discover a professional 3D printing powder supplier

PRODUCT PARAMETERS

Description

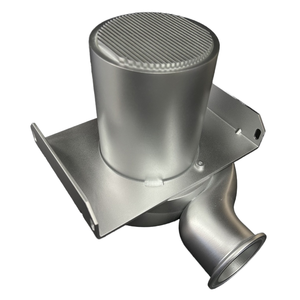

Overview of High accuracy SLA 3D printing steel aluminium metal rapid prototype model

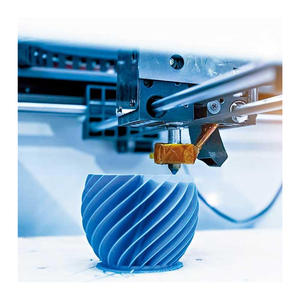

3D printing, also known as additive manufacturing, is a transformative technology that allows the creation of three-dimensional objects by depositing materials layer by layer based on digital designs. This process opens up a new world of possibilities in product design, customization, and production, revolutionizing various industries including healthcare, aerospace, automotive, consumer goods, and more.

Customization & Personalization: One of the key advantages of 3D printing is its ability to create highly customized products tailored to individual needs or preferences, from prosthetics to fashion accessories.

Complex Geometry: 3D printing excels at producing intricate shapes and geometries that would be extremely challenging or impossible to manufacture using conventional methods, such as internal lattice structures or organic forms.

Rapid Prototyping: It significantly speeds up the product development cycle by enabling designers and engineers to quickly produce physical prototypes for testing and refinement.

On-Demand Manufacturing: The technology supports small-batch or even one-off production runs economically, reducing the need for large inventories and allowing for just-in-time manufacturing.

Material Diversity: A wide range of materials can be used in 3D printing, including plastics, metals, ceramics, composites, and even biomaterials, each offering unique properties for specific applications.

Reduced Waste: As compared to subtractive manufacturing techniques, 3D printing only adds material where needed, leading to less waste and a more sustainable manufacturing process.

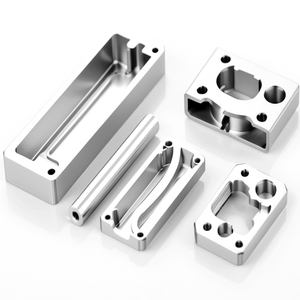

Features of High accuracy SLA 3D printing steel aluminium metal rapid prototype model

Design Flexibility: The technology enables the realization of complex designs without the constraints of traditional manufacturing tools and molds.

Functional Integration: Parts can be designed with integrated features such as channels, cavities, or interlocking components, which can enhance functionality or simplify assembly.

Lightweight Structures: Advanced 3D printing techniques allow for the creation of lightweight yet strong structures through optimized designs and the use of lattice structures or composite materials.

Improved Performance: By precisely controlling material composition and structure, 3D printed parts can exhibit enhanced mechanical, thermal, or electrical properties.

Cost-Efficiency for Complexity: While 3D printing may not always compete with mass-production methods for simple parts, it becomes increasingly cost-effective as the complexity of the part increases.

Innovative Applications: From medical implants that match a patient’s anatomy perfectly to aerospace components that reduce weight and increase efficiency, 3D printing pushes the boundaries of what’s possible in product design and engineering.

(High accuracy SLA 3D printing steel aluminium metal rapid prototype model)

Specification of High accuracy SLA 3D printing steel aluminium metal rapid prototype model

High-accuracy run-down neighborhood 3D printing creates exact steel and aluminum metal models for industries needing detailed and dependable models. This modern technology makes use of advanced stereolithography to build components layer by layer. It makes certain limited resistances and smooth coatings. The procedure suits fast prototyping and low-volume manufacturing.

The system supports steel and aluminum materials. These steels offer toughness and toughness for useful screening or end-use components. Layer resolution rises to 25 microns. This enables elaborate details and sharp sides. Dimensional accuracy stays within ± 0.1% of the layout. Parts match initial CAD data closely.

Printing rate is quick. Complex geometries take hours instead of days. This lowers preparations for projects. Post-processing consists of warm therapy or machining. These steps enhance mechanical residential properties and surface area quality. Components stand up to high anxiety and temperature levels.

Surface finishes are smooth. Added polishing or finishing is optional. This satisfies aesthetic or functional needs. The innovation benefits little to medium-sized components. Maximum construct dimension is 500 x 500 x 500 mm. Larger things can be divided and constructed post-printing.

Quality checks happen at every phase. Laser calibration ensures regular accuracy. Each component undertakes dimensional examination. Evaluating consists of tension evaluation and material confirmation. This guarantees reliability in real-world applications.

Applications cover aerospace, automobile, medical, and durable goods. Engineers utilize it for functional prototypes, jigs, and fixtures. Developers test kind and fit before mass production. Customized parts are made without expensive tooling.

Material alternatives consist of stainless-steel, aluminum alloys, and hybrid steels. These products withstand deterioration and wear. They suit severe atmospheres or heavy-use circumstances. Compatibility with CAD software program streamlines documents preparation. Layouts are published straight without intricate adjustments.

Support frameworks are minimized. This lowers material waste and cleaning time. Unused powder is recycled for future prints. The process continues to be affordable for little batches.

The innovation integrates with standard manufacturing. It connects prototyping and major manufacturing. Teams verify styles faster. Versions are simpler and more affordable. Errors are captured early. This stays clear of hold-ups in end product growth.

High-accuracy SLA 3D printing satisfies strict sector standards. It delivers steel models with professional-grade top quality. The method integrates rate, precision, and material adaptability.

(High accuracy SLA 3D printing steel aluminium metal rapid prototype model)

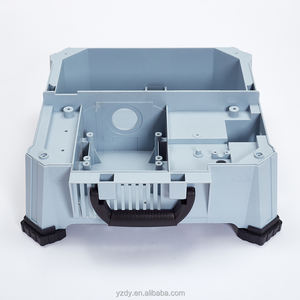

Applications of High accuracy SLA 3D printing steel aluminium metal rapid prototype model

High-accuracy SLA 3D printing for steel and aluminum metal rapid prototype models offers practical solutions across many industries. This technology creates detailed, durable parts quickly. It is ideal for testing designs before full production. Engineers and designers rely on it for precise models that match final products.

Aerospace companies use SLA 3D printing to make lightweight, strong components. These parts withstand extreme temperatures and stress. Complex shapes are easy to produce. This reduces the need for multiple manufacturing steps. Automotive manufacturers apply the technology for custom tools and engine parts. Prototypes are tested for performance and safety. Adjustments are made faster, cutting development time.

Medical fields benefit from SLA-printed metal models. Surgical tools and implants require high precision. The technology ensures accuracy for patient-specific designs. Dental labs create crowns and bridges with fine details. Customized medical devices improve patient outcomes.

Industrial equipment manufacturers use metal prototypes to test machinery parts. Functional models identify design flaws early. This prevents costly errors in mass production. Consumer electronics companies print heat-resistant casings and connectors. Small, intricate features are achieved without extra machining.

SLA 3D printing works with steel and aluminum alloys. These materials mimic the strength of traditional manufacturing. Parts are corrosion-resistant and suitable for harsh environments. Surface finishes are smooth, reducing post-processing work.

Speed is a key advantage. Prototypes are ready in days, not weeks. Businesses save time and resources. Low-volume production runs are cost-effective. Custom orders are handled efficiently.

The technology supports innovation across sectors. Design freedom allows complex geometries. Performance testing ensures reliability. Iterations are streamlined for faster product launches. Companies stay competitive by adopting advanced prototyping methods.

High-accuracy SLA 3D printing meets strict industry standards. It bridges the gap between concept and reality. Functional prototypes validate ideas quickly. Production risks are minimized. Businesses achieve better results with fewer delays.

Company Profile

3D Printing Passion is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality 3D printing powder and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality 3D printing materials and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of High accuracy SLA 3D printing steel aluminium metal rapid prototype model

What is high-accuracy SLA 3D printing for metal prototypes? This method uses stereolithography (SLA) technology to create precise metal models from steel or aluminum. A laser hardens liquid resin layer by layer. The result is a detailed prototype matching exact design specs. It suits industries needing complex geometries with tight tolerances.

Which metals work with this process? Steel and aluminum are common. Both metals are processed as fine powders mixed with resin. After printing, parts undergo sintering or heat treatment. This removes binders and solidifies the metal structure. The final product has properties similar to traditionally manufactured metal parts.

How accurate are these prototypes? Dimensional accuracy typically reaches ±0.1% or better. Features as small as 0.2 mm can be reproduced. This precision suits functional testing or parts requiring exact fits. Surface finishes are smooth, reducing post-processing. Variations depend on part size, geometry, and post-treatment methods.

What industries benefit from this technology? Aerospace, automotive, medical, and engineering sectors use it most. Applications include engine components, surgical tools, custom brackets, and functional prototypes. It speeds up product development by allowing rapid design validation. Small batches or one-off parts are cost-effective compared to traditional machining.

How long does production take? Lead times range from 3 to 7 days. This includes printing, sintering, and quality checks. Speed depends on part complexity and order volume. Urgent requests might have shorter timelines. Delays happen if designs need adjustments or post-processing requires extra steps.

(High accuracy SLA 3D printing steel aluminium metal rapid prototype model)