Discover a professional 3D printing powder supplier

PRODUCT PARAMETERS

Description

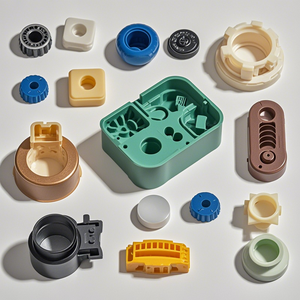

Overview of High Quality batch production rapid prototypes with 3D Printing Service

3D printing, also known as additive manufacturing, is a transformative technology that allows the creation of three-dimensional objects by depositing materials layer by layer based on digital designs. This process opens up a new world of possibilities in product design, customization, and production, revolutionizing various industries including healthcare, aerospace, automotive, consumer goods, and more.

Customization & Personalization: One of the key advantages of 3D printing is its ability to create highly customized products tailored to individual needs or preferences, from prosthetics to fashion accessories.

Complex Geometry: 3D printing excels at producing intricate shapes and geometries that would be extremely challenging or impossible to manufacture using conventional methods, such as internal lattice structures or organic forms.

Rapid Prototyping: It significantly speeds up the product development cycle by enabling designers and engineers to quickly produce physical prototypes for testing and refinement.

On-Demand Manufacturing: The technology supports small-batch or even one-off production runs economically, reducing the need for large inventories and allowing for just-in-time manufacturing.

Material Diversity: A wide range of materials can be used in 3D printing, including plastics, metals, ceramics, composites, and even biomaterials, each offering unique properties for specific applications.

Reduced Waste: As compared to subtractive manufacturing techniques, 3D printing only adds material where needed, leading to less waste and a more sustainable manufacturing process.

Features of High Quality batch production rapid prototypes with 3D Printing Service

Design Flexibility: The technology enables the realization of complex designs without the constraints of traditional manufacturing tools and molds.

Functional Integration: Parts can be designed with integrated features such as channels, cavities, or interlocking components, which can enhance functionality or simplify assembly.

Lightweight Structures: Advanced 3D printing techniques allow for the creation of lightweight yet strong structures through optimized designs and the use of lattice structures or composite materials.

Improved Performance: By precisely controlling material composition and structure, 3D printed parts can exhibit enhanced mechanical, thermal, or electrical properties.

Cost-Efficiency for Complexity: While 3D printing may not always compete with mass-production methods for simple parts, it becomes increasingly cost-effective as the complexity of the part increases.

Innovative Applications: From medical implants that match a patient’s anatomy perfectly to aerospace components that reduce weight and increase efficiency, 3D printing pushes the boundaries of what’s possible in product design and engineering.

(High Quality batch production rapid prototypes with 3D Printing Service)

Specification of High Quality batch production rapid prototypes with 3D Printing Service

High-quality batch production rapid prototypes made with 3D printing services deliver precision and efficiency for industrial and commercial projects. These prototypes use advanced technologies like SLA, SLS, and FDM to create accurate parts. Materials include durable plastics like ABS, PLA, and Nylon, plus resins and metals for specialized needs. Layer resolutions reach up to 25 microns, ensuring smooth surfaces and tight tolerances. This level of detail suits functional testing, product validation, and small-batch manufacturing.

The process starts with digital 3D models optimized for printability. Engineers check designs for potential issues before printing. Production scales easily from single units to hundreds of parts. Fast turnaround times meet urgent project deadlines. Automated printing systems maintain consistency across batches. Post-processing steps like sanding, painting, or chemical smoothing enhance part quality.

Strict quality control measures guarantee reliability. Each prototype undergoes dimensional checks using tools like calipers and CMM machines. Material certifications ensure compliance with industry standards. Testing for stress resistance, heat tolerance, and durability validates performance. Customization options cover colors, textures, and mechanical properties.

Cost-effectiveness comes from reduced material waste and efficient printing workflows. No expensive molds or tooling are needed. Design changes can be implemented quickly without delaying production. This flexibility supports iterative development cycles.

The service suits industries like automotive, aerospace, medical devices, and consumer electronics. Functional prototypes allow real-world testing before mass production. Small batches help verify manufacturing processes or gather user feedback. Technical support teams assist with design optimization and material selection.

High-speed printers handle complex geometries without sacrificing accuracy. Multi-material capabilities let one prototype combine rigid and flexible sections. Environmentally friendly options include recycled plastics and biodegradable resins. Secure data handling protects intellectual property during production.

Dependable shipping options ensure prototypes arrive on time. Packaging is tailored to prevent damage during transit. Real-time order tracking provides updates at every stage. Volume discounts make large batches more affordable.

The combination of advanced technology, rigorous testing, and adaptable workflows meets diverse prototyping needs. It bridges the gap between concept development and full-scale manufacturing.

(High Quality batch production rapid prototypes with 3D Printing Service)

Applications of High Quality batch production rapid prototypes with 3D Printing Service

High-quality batch production rapid prototypes made through 3D printing services are changing how industries develop products. These prototypes let businesses test designs quickly, improve ideas, and bring items to market faster. Many fields use this technology for different needs.

The automotive industry relies on 3D printing for creating precise prototype parts. Companies test engine components, interior fittings, and custom tools without waiting for traditional manufacturing. This speeds up development cycles and reduces costs.

Aerospace companies use rapid prototypes to build lightweight, complex parts. High-quality materials like heat-resistant plastics and metals ensure prototypes meet strict safety standards. Engineers check airflow systems, structural parts, and equipment housings before final production.

Medical device makers benefit from 3D printing for small-batch prototypes. Surgical tools, implants, and diagnostic equipment are tested for accuracy and usability. Custom solutions for patients, like prosthetics or dental guides, are made faster and at lower costs.

Consumer product brands use batch prototypes to test multiple designs at once. Electronics cases, household gadgets, and wearable devices are refined based on real-world feedback. Changes are made quickly, avoiding delays in mass production.

Electronics manufacturers print detailed prototypes for circuit housings, connectors, and heat-resistant parts. Functional testing ensures components fit perfectly and perform well under stress.

3D printing services support batch production with materials like nylon, resin, and metal alloys. Businesses produce dozens or hundreds of prototypes in one run. This method cuts waste and avoids expensive molds or specialized machinery.

High-quality rapid prototypes help companies stay competitive. Faster iterations mean fewer errors in final products. Teams collaborate better with physical models for review. Costs stay low while maintaining precision and durability.

Industries adopt 3D printing for batch prototypes because it works for many needs. Speed, flexibility, and reliability make it a key tool for modern manufacturing challenges.

Company Profile

3D Printing Passion is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality 3D printing powder and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality 3D printing materials and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of High Quality batch production rapid prototypes with 3D Printing Service

What materials are available for high-quality batch production prototypes?

We use common engineering-grade materials like ABS, PLA, nylon, resin, and metal alloys. These options balance strength, flexibility, and surface finish. Specialized materials like heat-resistant polymers or rubber-like TPU are available. Material choice depends on your project’s mechanical needs and appearance goals. Post-processing options include sanding, painting, or chemical smoothing to refine the final product.

How fast can you deliver batch prototypes?

Standard lead times range from 2 to 5 days after design approval. Rush services cut this to 24 hours for small batches. Speed depends on part complexity, material curing times, and order size. We optimize printer schedules to meet deadlines without sacrificing quality. Real-time order tracking keeps you updated.

What accuracy can I expect in 3D-printed batch prototypes?

Our industrial printers achieve layer resolutions up to 25 microns. Dimensional accuracy stays within ±0.1 mm for most materials. Tight tolerances are possible for critical features like mating surfaces or interlocking parts. Each batch undergoes random sampling with calipers and CMM checks. Design files are reviewed pre-print to prevent errors.

Is batch production cost-effective for prototypes?

Yes. 3D printing eliminates mold costs, making small batches affordable. Per-unit prices drop significantly for orders over 50 pieces. Costs depend on material type, part size, and post-processing needs. We provide upfront quotes with volume discounts. Compared to traditional methods, you save time and money while testing multiple iterations.

Can you handle large batch orders with consistent quality?

Our systems support batch sizes from 10 to 10,000+ units. Automated printing farms ensure uniformity across all parts. Quality control includes batch-specific documentation and material certifications. Dedicated printers are assigned to single projects to avoid cross-contamination. We scale capacity to meet demand spikes without delays.

(High Quality batch production rapid prototypes with 3D Printing Service)