Discover a professional 3D printing powder supplier

PRODUCT PARAMETERS

Description

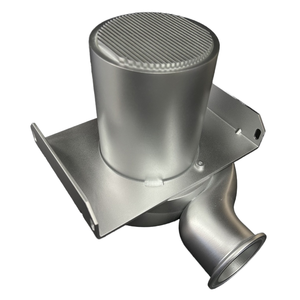

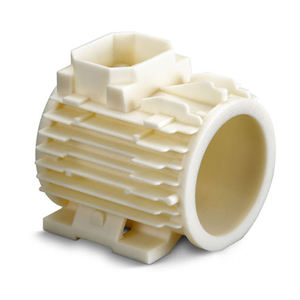

Overview of High Quality Product Develop Service Precision 3d Printing Service Plastic 3d Printing Parts

3D printing, also known as additive manufacturing, is a transformative technology that allows the creation of three-dimensional objects by depositing materials layer by layer based on digital designs. This process opens up a new world of possibilities in product design, customization, and production, revolutionizing various industries including healthcare, aerospace, automotive, consumer goods, and more.

Customization & Personalization: One of the key advantages of 3D printing is its ability to create highly customized products tailored to individual needs or preferences, from prosthetics to fashion accessories.

Complex Geometry: 3D printing excels at producing intricate shapes and geometries that would be extremely challenging or impossible to manufacture using conventional methods, such as internal lattice structures or organic forms.

Rapid Prototyping: It significantly speeds up the product development cycle by enabling designers and engineers to quickly produce physical prototypes for testing and refinement.

On-Demand Manufacturing: The technology supports small-batch or even one-off production runs economically, reducing the need for large inventories and allowing for just-in-time manufacturing.

Material Diversity: A wide range of materials can be used in 3D printing, including plastics, metals, ceramics, composites, and even biomaterials, each offering unique properties for specific applications.

Reduced Waste: As compared to subtractive manufacturing techniques, 3D printing only adds material where needed, leading to less waste and a more sustainable manufacturing process.

Features of High Quality Product Develop Service Precision 3d Printing Service Plastic 3d Printing Parts

Design Flexibility: The technology enables the realization of complex designs without the constraints of traditional manufacturing tools and molds.

Functional Integration: Parts can be designed with integrated features such as channels, cavities, or interlocking components, which can enhance functionality or simplify assembly.

Lightweight Structures: Advanced 3D printing techniques allow for the creation of lightweight yet strong structures through optimized designs and the use of lattice structures or composite materials.

Improved Performance: By precisely controlling material composition and structure, 3D printed parts can exhibit enhanced mechanical, thermal, or electrical properties.

Cost-Efficiency for Complexity: While 3D printing may not always compete with mass-production methods for simple parts, it becomes increasingly cost-effective as the complexity of the part increases.

Innovative Applications: From medical implants that match a patient’s anatomy perfectly to aerospace components that reduce weight and increase efficiency, 3D printing pushes the boundaries of what’s possible in product design and engineering.

(High Quality Product Develop Service Precision 3d Printing Service Plastic 3d Printing Parts)

Specification of High Quality Product Develop Service Precision 3d Printing Service Plastic 3d Printing Parts

Top notch product advancement services offer precision 3D printing for plastic components. These solutions focus on accuracy and reliability. Every task begins with an in-depth design testimonial. Engineers inspect measurements and material needs. This ensures the end product satisfies exact specs. Advanced 3D printing technology develops complicated geometries. It handles detailed information various other techniques might miss. Products include resilient plastics like ABS, Nylon, and polycarbonate. These plastics are selected for strength and versatility. They work well for practical models and end-use components.

The printing procedure utilizes industrial-grade makers. These machines generate layers as thin as 0.05 mm. This results in smooth surfaces and tight resistances. Post-processing options improve aesthetic appeals and efficiency. Fining sand, paint, or chemical smoothing get rid of layer lines. Components gain a specialist surface. Quality checks happen at every phase. Measurements are validated with precision devices. Examinations validate mechanical properties match demands.

Rate is a crucial advantage. Quick prototyping shortens advancement cycles. Styles move from concept to physical components in days. Small sets or big manufacturing runs are supported. Consistency remains high throughout all systems. Modification is basic. Style modifications are made rapidly without pricey tooling. This versatility matches markets like automobile, aerospace, and clinical gadgets.

Technical support is readily available throughout the procedure. Professionals aid maximize styles for 3D printing. They suggest adjustments to save time or minimize expenses. Documents are reviewed for print preparedness. Usual issues like wall thickness or assistance structures are resolved early. Secure data handling secures delicate projects.

Toughness testing makes certain parts perform under real-world conditions. Heat resistance, effect strength, and wear are evaluated. Results verify product choices and design stability. Ecological variables like UV exposure or dampness are evaluated when needed.

Cost efficiency originates from minimal waste. 3D printing utilizes just the material required for the part. Standard techniques usually subtract excess product. This makes 3D printing ideal for complex or lightweight layouts. Lead times stay predictable. Projects stay on timetable right away.

Trustworthy shipping alternatives supply parts globally. Product packaging protects elements during transportation. Tracking info is offered every order. Revisions or repeat orders follow the very same rigorous criteria. Consumer comments fine-tunes processes gradually.

(High Quality Product Develop Service Precision 3d Printing Service Plastic 3d Printing Parts)

Applications of High Quality Product Develop Service Precision 3d Printing Service Plastic 3d Printing Parts

Top quality precision 3D printing services provide practical remedies for product growth. These solutions produce plastic get rid of accuracy. Industries like auto, clinical, aerospace, and consumer goods rely on this modern technology. The process starts with digital layouts. Designers transform ideas right into physical things promptly. Models test form, fit, and feature before automation. This reduces mistakes and conserves time.

The automotive sector uses 3D printing for customized elements. Suppliers generate light-weight components for screening. Useful models simulate end products. Designers readjust designs based on real-world efficiency. Medical applications consist of surgical tools and patient-specific tools. Personalized prosthetics match private composition. Dental designs and implants are made faster.

Aerospace requires durable, specific components. 3D printing creates complicated geometries standard approaches can not. Elements endure high stress and temperature level. Fuel-efficient layouts lower weight without compromising strength. Consumer goods gain from fast prototyping. Business evaluate product designs swiftly. Custom-made product packaging, ergonomic tools, and household things reach markets faster.

Plastic products like ABS, nylon, and polycarbonate prevail. Each material suits various needs. Abdominal handles effect well. Nylon supplies adaptability. Polycarbonate withstands warm. Parts stay long lasting under severe problems.

3D printing cuts prices for little production runs. Typical tooling is expensive. Businesses prevent ahead of time financial investments. Style modifications occur right away production. Companies respond to consumer feedback faster.

Rate is a significant benefit. Models take hours rather than weeks. Product development cycles reduce. Companies release innovations faster. Custom orders fulfill certain client needs. Unique designs are possible without additional price.

High-quality 3D printing supports development throughout areas. It links the gap in between idea and truth. Services adapt to market modifications successfully. The technology remains to advance. New materials and methods broaden possibilities. Industries discover fresh means to resolve old problems.

Company Profile

3D Printing Passion is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality 3D printing powder and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality 3D printing materials and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of High Quality Product Develop Service Precision 3d Printing Service Plastic 3d Printing Parts

What materials do you use for plastic 3D printing parts? Common materials include ABS, PLA, PETG, and nylon. These plastics are chosen for strength, flexibility, and heat resistance. Each material suits different applications. ABS works for durable prototypes. PLA is eco-friendly and good for simple models. PETG handles impact-resistant parts. Nylon fits components needing high wear resistance.

How precise are your 3D printed parts? Precision stays within ±0.1mm to ±0.3mm. This depends on the printer type and part complexity. High-end printers ensure tight tolerances. Design optimization also affects accuracy. Complex geometries may need support structures. These factors are reviewed before printing to meet specifications.

What is the typical production time? Small parts finish in 1-2 days. Larger projects take 3-7 days. Time varies with part size, material, and post-processing needs. Sanding, painting, or assembly add extra time. Rush services are available. Timelines are confirmed before starting.

Which industries do you serve? Automotive, aerospace, medical, and consumer goods sectors use our services. Automotive teams test prototypes. Aerospace requires lightweight components. Medical devices need biocompatible materials. Consumer products use detailed models. Custom solutions are offered for unique needs.

How do you ensure quality? Multiple checks happen during and after printing. Layers are inspected for defects. Finished parts undergo dimensional testing. Tools like calipers and CMM machines verify accuracy. Materials are tested for performance. Certifications like ISO 9001 guarantee standards. Quality reports are provided with each order.

(High Quality Product Develop Service Precision 3d Printing Service Plastic 3d Printing Parts)