Discover a professional 3D printing powder supplier

PRODUCT PARAMETERS

Description

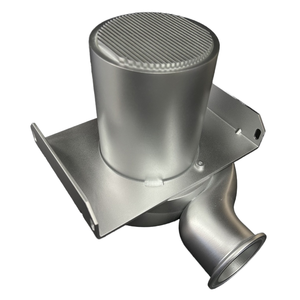

Overview of Oem 3d Printed Fabrics Products Service Custom Resin Plastic Nylon Rapid Prototyping 3d Printing Service

3D printing, also known as additive manufacturing, is a transformative technology that allows the creation of three-dimensional objects by depositing materials layer by layer based on digital designs. This process opens up a new world of possibilities in product design, customization, and production, revolutionizing various industries including healthcare, aerospace, automotive, consumer goods, and more.

Customization & Personalization: One of the key advantages of 3D printing is its ability to create highly customized products tailored to individual needs or preferences, from prosthetics to fashion accessories.

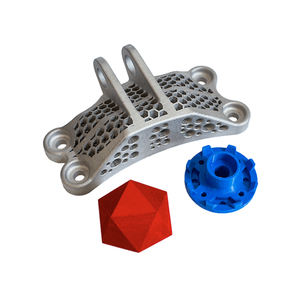

Complex Geometry: 3D printing excels at producing intricate shapes and geometries that would be extremely challenging or impossible to manufacture using conventional methods, such as internal lattice structures or organic forms.

Rapid Prototyping: It significantly speeds up the product development cycle by enabling designers and engineers to quickly produce physical prototypes for testing and refinement.

On-Demand Manufacturing: The technology supports small-batch or even one-off production runs economically, reducing the need for large inventories and allowing for just-in-time manufacturing.

Material Diversity: A wide range of materials can be used in 3D printing, including plastics, metals, ceramics, composites, and even biomaterials, each offering unique properties for specific applications.

Reduced Waste: As compared to subtractive manufacturing techniques, 3D printing only adds material where needed, leading to less waste and a more sustainable manufacturing process.

Features of Oem 3d Printed Fabrics Products Service Custom Resin Plastic Nylon Rapid Prototyping 3d Printing Service

Design Flexibility: The technology enables the realization of complex designs without the constraints of traditional manufacturing tools and molds.

Functional Integration: Parts can be designed with integrated features such as channels, cavities, or interlocking components, which can enhance functionality or simplify assembly.

Lightweight Structures: Advanced 3D printing techniques allow for the creation of lightweight yet strong structures through optimized designs and the use of lattice structures or composite materials.

Improved Performance: By precisely controlling material composition and structure, 3D printed parts can exhibit enhanced mechanical, thermal, or electrical properties.

Cost-Efficiency for Complexity: While 3D printing may not always compete with mass-production methods for simple parts, it becomes increasingly cost-effective as the complexity of the part increases.

Innovative Applications: From medical implants that match a patient’s anatomy perfectly to aerospace components that reduce weight and increase efficiency, 3D printing pushes the boundaries of what’s possible in product design and engineering.

(Oem 3d Printed Fabrics Products Service Custom Resin Plastic Nylon Rapid Prototyping 3d Printing Service)

Specification of Oem 3d Printed Fabrics Products Service Custom Resin Plastic Nylon Rapid Prototyping 3d Printing Service

OEM 3D Printed Fabrics Products Solution provides personalized services for quick prototyping and manufacturing using advanced 3D printing technologies. The solution sustains materials like resin, plastic, and nylon, satisfying diverse market needs. Customers can request tailored layouts for functional models, end-use components, or fabric-inspired structures. The procedure starts with electronic designs, which are maximized for publishing to guarantee precision and architectural integrity.

The service deals with tasks of differing intricacy. Applications include automobile elements, fashion devices, commercial devices, and durable goods. Layer resolutions range from 20 to 100 microns, stabilizing detail and rate. Build quantities suit parts approximately 500mm in dimension, ideal for small to medium-sized items. Product options depend on job requirements. Material offers smooth finishes and great details. Plastic offers resilience and adaptability. Nylon masters stamina and warm resistance.

Quality assurance procedures are rigorous. Printed parts undertake dimensional checks and cardiovascular test. Post-processing choices like sanding, paint, or finishing are available. Preparations are short. Prototypes usually ship within 1-3 days. Manufacturing orders range based on volume, with mass price cuts for huge amounts.

Design assistance is included. Engineers help with documents prep work, wall density adjustments, and assistance structure optimization. Documents approved include STL, OBJ, and STEP styles. Pricing depends on product, print time, and labor. Quotes are offered within 24 hours after assessing job information.

The solution focuses on discretion. Customer layouts stay safe with encrypted data transfers and non-disclosure arrangements. Sustainability practices reduce waste using efficient printing approaches and recyclable products.

Clients benefit from streamlined buying. An on the internet system allows immediate uploads, real-time quotes, and order monitoring. Technical assistance is readily available for fixing or layout adjustments. Global delivery alternatives guarantee prompt distribution.

The innovation matches start-ups and established brand names. It minimizes traditional manufacturing expenses and speeds up item growth. Personalized textures resemble woven fabrics for realistic prototypes in fashion or interior decoration. Practical components fulfill market standards for mechanical performance.

Customers obtain updates at each manufacturing phase. Revisions are feasible before final printing. Comments loopholes make certain alignment with assumptions. The service intends to simplify access to high-grade 3D printing without endangering precision or creative thinking.

(Oem 3d Printed Fabrics Products Service Custom Resin Plastic Nylon Rapid Prototyping 3d Printing Service)

Applications of Oem 3d Printed Fabrics Products Service Custom Resin Plastic Nylon Rapid Prototyping 3d Printing Service

OEM 3D printed textiles products and services supply customized remedies for markets requiring flexible, resilient products. These solutions make use of sophisticated 3D printing innovation to develop fabrics from resin, plastic, and nylon. The applications are wide-ranging. Fashion designers utilize 3D printed materials to generate elaborate patterns and textures impossible with conventional methods. Automotive business incorporate these products into light-weight indoor components, decreasing vehicle weight while maintaining strength. Medical care sectors take advantage of personalized clinical tools like breathable prosthetics or wearable supports customized to patient requirements.

The option of materials matters. Material uses high information for models needing specific surfaces. Plastic guarantees durability for useful parts like gears or real estates. Nylon stands out for adaptability, suitable for hinges or relocating elements. Fast prototyping speeds up product development. Organizations evaluate layouts quickly, determine defects early, and fine-tune items faster. This decreases costs and reduces time-to-market.

Personalization is vital. OEM solutions adapt to details client requirements. Changes in structure, density, or mechanical buildings are possible. Clients request examples, examine them, and supply comments for fine-tuning. This collaborative technique ensures end products satisfy specific criteria.

3D printing technology itself drives efficiency. It develops layer-by-layer, decreasing material waste. Complex geometries are possible without costly mold and mildews or devices. Little batches or solitary models are economical. Industries like aerospace usage this for lightweight, high-strength components that hold up against severe problems.

The solution sustains quick turnaround times. Orders relocate from digital models to physical products in days. Clients upload designs, choose products, and get completed things promptly. This speed is critical for sectors encountering limited due dates or quick layout modifications.

Businesses across sectors count on OEM 3D published fabrics for advancement and usefulness. The mix of product adaptability, fast prototyping, and customized solutions addresses modern production difficulties. It allows companies to experiment freely, optimize layouts, and deliver top quality items effectively.

Company Profile

3D Printing Passion is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality 3D printing powder and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality 3D printing materials and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Oem 3d Printed Fabrics Products Service Custom Resin Plastic Nylon Rapid Prototyping 3d Printing Service

What materials do you offer? We provide resin, plastic, nylon. These materials work for different needs. Resin suits detailed prototypes. Plastic handles durable parts. Nylon is good for flexible items. You can pick based on your project.

How fast is the turnaround time? Production takes 1-3 days. It depends on size, complexity. Small parts finish quicker. Complex designs need more time. We start after confirming your design.

How precise are the prints? Our machines achieve ±0.1 mm accuracy. Details like thin walls or small holes come out clear. Surface finish varies by material. Resin gives smoother results. Plastic or nylon might need extra polishing.

What affects the cost? Cost depends on material type, part size, printing time. Bigger parts use more material. Complex designs take longer to print. We give a quote after reviewing your file.

Can you help with design files? Yes. We accept STEP, STP, OBJ formats. Our team checks your files for errors. We fix issues like wall thickness or unsupported structures. Send your design first. We confirm if it’s ready for printing.

(Oem 3d Printed Fabrics Products Service Custom Resin Plastic Nylon Rapid Prototyping 3d Printing Service)