Discover a professional 3D printing powder supplier

PRODUCT PARAMETERS

Description

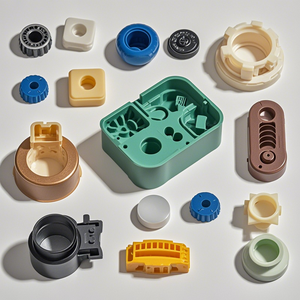

Overview of OEM 3d printed fabrics products service custom resin plastic nylon rapid prototyping sls 3d printing service

3D printing, also known as additive manufacturing, is a transformative technology that allows the creation of three-dimensional objects by depositing materials layer by layer based on digital designs. This process opens up a new world of possibilities in product design, customization, and production, revolutionizing various industries including healthcare, aerospace, automotive, consumer goods, and more.

Customization & Personalization: One of the key advantages of 3D printing is its ability to create highly customized products tailored to individual needs or preferences, from prosthetics to fashion accessories.

Complex Geometry: 3D printing excels at producing intricate shapes and geometries that would be extremely challenging or impossible to manufacture using conventional methods, such as internal lattice structures or organic forms.

Rapid Prototyping: It significantly speeds up the product development cycle by enabling designers and engineers to quickly produce physical prototypes for testing and refinement.

On-Demand Manufacturing: The technology supports small-batch or even one-off production runs economically, reducing the need for large inventories and allowing for just-in-time manufacturing.

Material Diversity: A wide range of materials can be used in 3D printing, including plastics, metals, ceramics, composites, and even biomaterials, each offering unique properties for specific applications.

Reduced Waste: As compared to subtractive manufacturing techniques, 3D printing only adds material where needed, leading to less waste and a more sustainable manufacturing process.

Features of OEM 3d printed fabrics products service custom resin plastic nylon rapid prototyping sls 3d printing service

Design Flexibility: The technology enables the realization of complex designs without the constraints of traditional manufacturing tools and molds.

Functional Integration: Parts can be designed with integrated features such as channels, cavities, or interlocking components, which can enhance functionality or simplify assembly.

Lightweight Structures: Advanced 3D printing techniques allow for the creation of lightweight yet strong structures through optimized designs and the use of lattice structures or composite materials.

Improved Performance: By precisely controlling material composition and structure, 3D printed parts can exhibit enhanced mechanical, thermal, or electrical properties.

Cost-Efficiency for Complexity: While 3D printing may not always compete with mass-production methods for simple parts, it becomes increasingly cost-effective as the complexity of the part increases.

Innovative Applications: From medical implants that match a patient’s anatomy perfectly to aerospace components that reduce weight and increase efficiency, 3D printing pushes the boundaries of what’s possible in product design and engineering.

(OEM 3d printed fabrics products service custom resin plastic nylon rapid prototyping sls 3d printing service)

Specification of OEM 3d printed fabrics products service custom resin plastic nylon rapid prototyping sls 3d printing service

Required customized 3D published fabric-like parts? Our OEM service concentrates on generating them utilizing sophisticated SLS (Selective Laser Sintering) innovation. We publish straight from your digital layouts, creating long lasting, functional models or end-use components. This process is perfect for complicated geometries and detailed textures mimicking woven or weaved fabrics.

We largely use fine nylon powder for SLS printing. Nylon provides outstanding toughness, adaptability, and warm resistance. It feels smooth and handles well. This material selection is crucial for parts requiring to curtain, flex, or endure stress and anxiety, similar to genuine fabric. We also supply various other engineering-grade plastic powders upon ask for specific requirements.

Our SLS devices supply high precision. Typical layer density is around 0.1 mm to 0.12 mm. This fine resolution captures subtle information necessary for textile textures. We achieve tolerances generally within +/- 0.3 mm. Parts appear of the machine needing marginal finishing. They have a slightly grainy surface area feel, similar to great sandpaper. This structure can be smoothed additionally if needed.

The procedure is fast. We construct components layer by layer straight from powder, no support structures required. This quicken manufacturing significantly. It also allows complicated, interlacing designs difficult with various other techniques. Typical preparation are short, typically simply a couple of days. We scale manufacturing quickly from solitary models to larger sets.

We deal with whatever in-house. Upload your 3D design (STL file favored). Our team evaluates it for printability. We encourage on any necessary modifications. We handle the whole SLS printing procedure, post-processing, and quality checks. We ship the completed parts straight to you. Our objective is reliable, premium customized parts made specifically to your specifications. We concentrate on supplying practical outcomes promptly.

(OEM 3d printed fabrics products service custom resin plastic nylon rapid prototyping sls 3d printing service)

Applications of OEM 3d printed fabrics products service custom resin plastic nylon rapid prototyping sls 3d printing service

OEM 3D published textiles supply new services. Designers utilize this service for one-of-a-kind fashion items. They develop uncommon textures and patterns difficult with conventional weaving. The vehicle industry utilizes personalized material and nylon parts. These parts are lightweight. They change heavier products inside cars. This enhances gas performance. Medical fields benefit substantially. Prosthetics and orthotics require perfect fits. SLS 3D printing makes personalized devices promptly. These gadgets match patient composition exactly. Comfort boosts a great deal. Architects utilize rapid prototyping for in-depth building models. They show intricate appearances and structures plainly. Customers understand the layouts better. Durable goods companies require quick modification. They make bespoke phone cases and wearable technology components. Plastic and nylon printing handles small batches efficiently. Industrial designers require functional models quick. They check parts under actual conditions. SLS printing makes strong, sturdy models. This solution makes use of materials like nylon and resin. It produces complex, interlocked fabric-like frameworks. Manufacturers obtain parts much faster than typical approaches. Costs remain reduced for small runs. Layout flexibility is a lot higher. Facility geometries are simple. Developers check out forms without limits. The process sustains rapid iteration. Teams fine-tune styles swiftly. They obtain items to market quicker. This service is perfect for specialized applications needing one-of-a-kind product residential or commercial properties.

Company Profile

3D Printing Passion is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality 3D printing powder and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality 3D printing materials and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of OEM 3d printed fabrics products service custom resin plastic nylon rapid prototyping sls 3d printing service

What materials do you offer for fabric-like 3D prints?

We mainly use nylon powders. Nylon 11 and Nylon 12 work best. They create flexible, durable parts. These parts feel similar to woven fabrics. We also use some specialty resins. These resins mimic soft textures. Material choice depends on your project needs. Tell us what you require.

How smooth is the surface finish?

SLS prints have a slightly grainy texture. Think fine sandpaper. This is normal for the process. We can smooth parts after printing. Techniques include media tumbling or light coatings. Smoothing adds time and cost. Discuss your finish requirements with us. We find the best solution.

How fast can you make prototypes?

Turnaround is usually quick. Often 3-5 business days. Complex designs or large orders take longer. We prioritize speed for prototyping. Production volumes need more planning. Send us your files early. We give you an exact timeline.

What design rules apply to SLS fabrics?

SLS is very flexible. It handles complex shapes well. Overhangs and intricate details are fine. No support structures are needed. The powder supports the part during printing. Wall thickness matters. Very thin walls might be too fragile. We recommend walls at least 1mm thick. Share your design. We check it for printability.

What affects the cost per part?

Cost depends on several things. Material type is one factor. Nylon costs less than some specialty resins. Part size and volume matter. Bigger parts use more material. Ordering more parts lowers the unit cost. Surface finishing adds expense. Complex designs might need more machine time. We provide quotes based on your specific project. Send us your details for pricing.

(OEM 3d printed fabrics products service custom resin plastic nylon rapid prototyping sls 3d printing service)