Discover a professional 3D printing powder supplier

PRODUCT PARAMETERS

Description

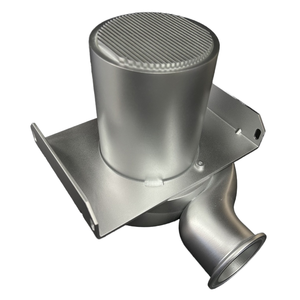

Overview of OEM cnc machining ABS rapid prototyping 3D printing auto parts household product

3D printing, also known as additive manufacturing, is a transformative technology that allows the creation of three-dimensional objects by depositing materials layer by layer based on digital designs. This process opens up a new world of possibilities in product design, customization, and production, revolutionizing various industries including healthcare, aerospace, automotive, consumer goods, and more.

Customization & Personalization: One of the key advantages of 3D printing is its ability to create highly customized products tailored to individual needs or preferences, from prosthetics to fashion accessories.

Complex Geometry: 3D printing excels at producing intricate shapes and geometries that would be extremely challenging or impossible to manufacture using conventional methods, such as internal lattice structures or organic forms.

Rapid Prototyping: It significantly speeds up the product development cycle by enabling designers and engineers to quickly produce physical prototypes for testing and refinement.

On-Demand Manufacturing: The technology supports small-batch or even one-off production runs economically, reducing the need for large inventories and allowing for just-in-time manufacturing.

Material Diversity: A wide range of materials can be used in 3D printing, including plastics, metals, ceramics, composites, and even biomaterials, each offering unique properties for specific applications.

Reduced Waste: As compared to subtractive manufacturing techniques, 3D printing only adds material where needed, leading to less waste and a more sustainable manufacturing process.

Features of OEM cnc machining ABS rapid prototyping 3D printing auto parts household product

Design Flexibility: The technology enables the realization of complex designs without the constraints of traditional manufacturing tools and molds.

Functional Integration: Parts can be designed with integrated features such as channels, cavities, or interlocking components, which can enhance functionality or simplify assembly.

Lightweight Structures: Advanced 3D printing techniques allow for the creation of lightweight yet strong structures through optimized designs and the use of lattice structures or composite materials.

Improved Performance: By precisely controlling material composition and structure, 3D printed parts can exhibit enhanced mechanical, thermal, or electrical properties.

Cost-Efficiency for Complexity: While 3D printing may not always compete with mass-production methods for simple parts, it becomes increasingly cost-effective as the complexity of the part increases.

Innovative Applications: From medical implants that match a patient’s anatomy perfectly to aerospace components that reduce weight and increase efficiency, 3D printing pushes the boundaries of what’s possible in product design and engineering.

(OEM cnc machining ABS rapid prototyping 3D printing auto parts household product)

Specification of OEM cnc machining ABS rapid prototyping 3D printing auto parts household product

This product covers OEM CNC machining, ABS rapid prototyping, 3D printing, and custom production for auto components and household products. Precision engineering ensures top notch outcomes across all services. CNC machining manages steels and plastics, generating parts with tight resistances up to ± 0.01 mm. Surface area finishes range from harsh milling to sleek appearances. ABS quick prototyping sustains rapid turnaround times, perfect for useful screening or design validation. The procedure makes use of industrial-grade thermoplastics for durability and warmth resistance.

3D printing services consist of FDM and run-down neighborhood modern technologies. Layer resolutions begin at 0.05 mm, appropriate for complicated geometries and fine details. Materials consist of ABS, nylon, and resin. Automotive components concentrate on engine components, interior installations, and custom-made braces. These components fulfill standards for resonance resistance and thermal stability. House products cover kitchen tools, storage space remedies, and ornamental products. Designs prioritize ergonomics and simplicity of usage.

Modification choices include material option, surface types, and dimensional changes. Manufacturing scales from single models to bulk orders. Preparations vary: models take 1-3 days, automation includes 2-5 weeks. Quality assurance involves coordinate determining machines (CMM) and hand-operated evaluations. Qualifications adhere to ISO 9001 and industry-specific standards.

Abdominal products are UV-stabilized for exterior applications. CNC-machined automotive parts undergo stress and anxiety analysis to make sure load-bearing ability. Family products feature food-safe or child-safe finishes. 3D-printed prototypes sustain snap-fit settings up and moving components. Technical illustrations or 3D documents are approved for manufacturing. Submit styles consist of STEP, IGES, and STL.

Machining facilities run with 3 to 5 axes for multi-angle handling. Fast prototyping equipments attain quicken to 1 day per medium-sized component. Post-processing includes sanding, paint, and electroplating. Packaging alternatives shield parts during delivery. Automotive elements are tested for fitment in OEM systems. Household products undergo wear-and-tear simulations.

Rates depends on material prices, labor, and order volume. Discounts get repeat projects. Design assistance is offered for optimizing manufacturability. Examples can be asked for before full production. Revisions are permitted during the prototyping stage. Technical teams help with material choice or design difficulties.

(OEM cnc machining ABS rapid prototyping 3D printing auto parts household product)

Applications of OEM cnc machining ABS rapid prototyping 3D printing auto parts household product

Industries today depend on OEM CNC machining and ABS fast prototyping to produce top notch parts rapidly. These methods work well for vehicle and household items. CNC machining utilizes computer-controlled tools to form ABS plastic right into accurate components. This is suitable for automobile components like engine installs, dashboard panels, or interior trim. The process guarantees limited resistances and resilience, which automobile producers need for safety and performance. ABS fast prototyping assists evaluate designs before automation. Designers can adjust forms or fix imperfections early, conserving time and expenses. 3D printing includes adaptability. It develops complex geometries layer by layer, making customized auto components like brackets or connectors without costly mold and mildews. Tiny cars and truck brand names or repair shops benefit from this affordable strategy.

House products additionally use these modern technologies. ABS plastic is strong and light-weight, excellent for things like kitchen utensils, tool handles, or home appliance housings. CNC machining produces smooth coatings for visible parts, such as ornamental panels or furniture parts. Quick prototyping lets designers experiment with ergonomic shapes for much better customer comfort. 3D printing supports small-batch production of niche things like personalized coordinators or replacement components for older appliances. Home goods brand names can evaluate new ideas much faster and respond to market patterns without big in advance financial investments.

These techniques minimize waste compared to typical production. CNC makers reduced product precisely, lessening extra. 3D printing makes use of just the plastic required for each and every component. ABS plastic is recyclable, aligning with green goals. Automobile and home item business worth this performance for lasting operations. Speed issues also. CNC machining and 3D printing shorten manufacturing timelines, allowing businesses fulfill limited deadlines or deal with immediate orders. Customization is easier. Customers can request tweaks to designs without reducing the process.

Durability remains a crucial advantage. Abdominal plastic stands up to effects, warmth, and chemicals, making it trusted for auto components revealed to engine warmth or household things facing daily wear. CNC-machined parts keep uniformity across huge batches, ensuring every product meets top quality criteria. 3D printing permits elaborate information that standard approaches could miss out on, boosting functionality in products like equipments or hinges. Expense financial savings bring in start-ups and developed brand names alike. Reduced tooling expenses and faster turn-around times make these technologies available for tasks of any type of scale.

Company Profile

3D Printing Passion is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality 3D printing powder and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality 3D printing materials and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of OEM cnc machining ABS rapid prototyping 3D printing auto parts household product

What materials work best for OEM CNC machining rapid prototyping? ABS plastic is the top choice. It is strong, handles heat well, costs less than many options. Other materials like nylon, polycarbonate, or metals can be used if needed. ABS suits most projects needing toughness and stability.

Why pick ABS for 3D printing auto parts? ABS resists wear, chemicals, high temperatures common in vehicles. It machines smoothly, keeps precise shapes during production. Parts made with ABS last longer, survive harsh conditions better than basic plastics. This makes it reliable for car components.

Can household products be made using CNC machining with ABS? Yes. Items like kitchen tools, appliance parts, storage containers benefit from ABS. The material stays sturdy, handles daily use without breaking. Custom shapes, textures, sizes are easy to achieve. This flexibility helps create functional, attractive home goods.

How accurate is CNC machining for ABS prototypes? Tolerances reach ±0.1mm. CNC machines cut ABS with high precision, matching exact design specs. This level of detail ensures parts fit correctly, work as intended. Testing prototypes early avoids errors in mass production later.

What is the average lead time for ABS rapid prototyping? Most orders finish in 1-2 weeks. Complexity, quantity, post-processing steps affect timelines. Simple designs ship faster. Engineers review each project first, confirm deadlines before starting. Rush services may shorten waits if needed.

(OEM cnc machining ABS rapid prototyping 3D printing auto parts household product)