Discover a professional 3D printing powder supplier

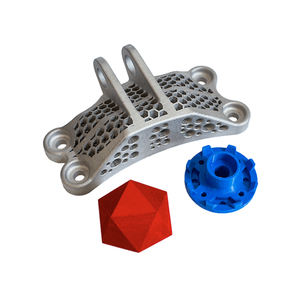

3D Printed Product

2023 Innovative Products 1kg / 1.75mm / 2.85mm Polymaker PolyLite Printer 3D Printing PETG Filament

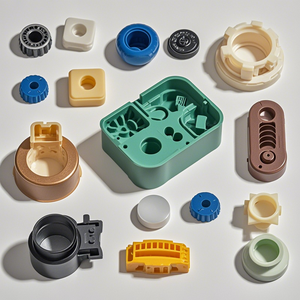

High Precision Custom Cnc Machining Abs Plastic Part Prototyping Plastic 3D Printing Service Printing Rapid Prototype

Hot ing 3d Printing Filament Extruder machine Plastic filament machine

Custom 3D Printing Prototypes SLA SLS Printing For Customized ABS TPU Nylon Resin Metal Anime Model 3D Printing Service

custom Manufacturing Plastic products rapid prototyping 3d printing service

ABS/PLA 3D printing filament extruder product zhangjiagang friendmachinery suzhou acc machinery

Electronic product shell prototype/parts plastic resin rapid prototyping/3D printing service

Action Figure Model Design SLA SLS 3D Printing Service for Plastic Rapid Prototype

Cheap rapid prototyping 3D printing service plastic prototype CNC machining parts aluminum turning service cnc prototype

Manufacture Vendors 3D Printing High Precision Online 3D Printers Printing Shops 3D Steel Printing Service

OEM Manufacturing SLA SLS Resin Nylon Mold Printing ABS Plastic Rapid Prototyping 3D Printing Service

CNC Machining 3D Printing Service Engineering Plastic 3D Printing CNC

Introduction of 3D printed products

3D printing (additive manufacturing) is a technology that manufactures three-dimensional objects by stacking materials (such as plastics, metals, resins, etc.) layer by layer. It is based on digital model files and can achieve rapid prototyping of complex structures. It is widely used in industries, medical care, education and other fields.

Characteristics of 3D printed products

High customization: flexible design of personalized structures.

Complex structure molding: hollowing, embedded and other structures that are difficult to achieve with traditional processes.

Rapid prototyping: shorten product development cycle.

Diverse materials: support materials such as plastics, metals, and ceramics.

Reduce waste: use only necessary materials, more environmentally friendly.

Specifications of 3D printed products

| Parameter | Details |

|---|---|

| Technology | FDM, SLA, SLS, DMLS, etc. |

| Material | PLA, ABS, Resin, Metal, etc. |

| Layer Height | 0.05–0.3 mm |

| Print Speed | 20–150 mm/s |

| Accuracy | ±0.1–0.5 mm |

| Max. Size | Varies by printer (e.g., 200×200×200 mm) |

| Post-Processing | Sanding, Painting, Curing |

Application of 3D printed products

Industry: prototyping, mold development, lightweight parts.

Medical: customized prostheses, dental models, bioprinting.

Consumption: personalized accessories, household items.

Education: teaching models, scientific research experimental tools.

Aerospace: high-strength lightweight components.

Company Profile

3D Printing Passion is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality 3D printing powder and relative products.The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.If you are looking for high-quality 3D printing materials and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of 3D printed products

What are the materials for 3D printing?

Common materials include PLA, ABS, resin, titanium alloy, etc.

How accurate is 3D printing?

Usually 0.1–0.3 mm, and high-precision equipment can reach micron level.

How long does it take to print an object?

The time varies depending on the size and complexity, ranging from a few minutes to several days.

How strong are 3D printed products?

Depending on the material and post-processing, metal prints can reach the strength of traditional processes.

Is 3D printing suitable for mass production?

Currently, it is mostly used for small batch customization, but industrial-grade technology is gradually expanding.