Discover a professional 3D printing powder supplier

PRODUCT PARAMETERS

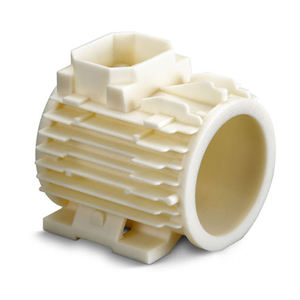

Description

Overview of PETG 3D printing filament extruder machinery production line

3D printing, also known as additive manufacturing, is a transformative technology that allows the creation of three-dimensional objects by depositing materials layer by layer based on digital designs. This process opens up a new world of possibilities in product design, customization, and production, revolutionizing various industries including healthcare, aerospace, automotive, consumer goods, and more.

Customization & Personalization: One of the key advantages of 3D printing is its ability to create highly customized products tailored to individual needs or preferences, from prosthetics to fashion accessories.

Complex Geometry: 3D printing excels at producing intricate shapes and geometries that would be extremely challenging or impossible to manufacture using conventional methods, such as internal lattice structures or organic forms.

Rapid Prototyping: It significantly speeds up the product development cycle by enabling designers and engineers to quickly produce physical prototypes for testing and refinement.

On-Demand Manufacturing: The technology supports small-batch or even one-off production runs economically, reducing the need for large inventories and allowing for just-in-time manufacturing.

Material Diversity: A wide range of materials can be used in 3D printing, including plastics, metals, ceramics, composites, and even biomaterials, each offering unique properties for specific applications.

Reduced Waste: As compared to subtractive manufacturing techniques, 3D printing only adds material where needed, leading to less waste and a more sustainable manufacturing process.

Features of PETG 3D printing filament extruder machinery production line

Design Flexibility: The technology enables the realization of complex designs without the constraints of traditional manufacturing tools and molds.

Functional Integration: Parts can be designed with integrated features such as channels, cavities, or interlocking components, which can enhance functionality or simplify assembly.

Lightweight Structures: Advanced 3D printing techniques allow for the creation of lightweight yet strong structures through optimized designs and the use of lattice structures or composite materials.

Improved Performance: By precisely controlling material composition and structure, 3D printed parts can exhibit enhanced mechanical, thermal, or electrical properties.

Cost-Efficiency for Complexity: While 3D printing may not always compete with mass-production methods for simple parts, it becomes increasingly cost-effective as the complexity of the part increases.

Innovative Applications: From medical implants that match a patient’s anatomy perfectly to aerospace components that reduce weight and increase efficiency, 3D printing pushes the boundaries of what’s possible in product design and engineering.

(PETG 3D printing filament extruder machinery production line)

Specification of PETG 3D printing filament extruder machinery production line

This PETG filament assembly line makes premium quality 3D printing spools. The system begins with raw PETG pellets. These pellets feed into a large receptacle. The hopper manages pellet flow into the extruder barrel. Effective heating systems border the barrel. The warm melts the PETG pellets entirely. A solid screw inside the barrel pushes the thawed plastic onward. The screw mixes the melted PETG quite possibly. This mixing makes sure even worldly residential or commercial properties. The thawed PETG moves with an unique shaping device. This tool forms the melted plastic right into a thin strand. The strand comes out of the device head. The hair relocates right into a cooling water bathroom quickly. The water bathroom cools down the strand quickly. Rapid air conditioning sets the hair form correctly. The hair leaves the water bath. Air blades blow pressed air onto the hair. This air removes extra water beads. The hair takes a trip with accuracy measurement gadgets. These devices continuously check the strand density. The sensors send out thickness data to the control system. The control system changes the puller rollers rate. This modification keeps the strand size exact. Constant size is important for reliable 3D printing. The hair relocates onto the winding device. The winder curls the cooled, determined strand onto spools. The spooling tension is very carefully regulated. Excellent stress stops loose or tangled filament. The ended up spools are ready for packaging. Operators keep track of the whole line constantly. The equipment runs successfully with very little downtime. This configuration generates PETG filament conference stringent sector criteria.

(PETG 3D printing filament extruder machinery production line)

Applications of PETG 3D printing filament extruder machinery production line

PETG 3D printing filament extruder equipment production lines produce essential material. PETG filament is incredibly popular. It provides excellent toughness and sturdiness. It is also reasonably very easy to print with. This makes it ideal for various individuals. PETG stands up to influences well. It takes care of chemicals much better than a few other common filaments. It is additionally food-safe oftentimes. This product is clearer than abdominal. It is less breakable than PLA. These residential or commercial properties drive need for top quality PETG filament.

Our equipment assembly line meet this need effectively. They turn raw PETG pellets into constant, dependable filament. Accurate temperature control is essential. The equipments handle this throughout the entire extrusion procedure. Regular heating makes certain the dissolved PETG streams smoothly. This avoids problems like bubbles or uneven density. The outcome is filament with a best diameter. Diameter consistency is vital for hassle-free 3D printing.

These production lines are constructed for stability and outcome. They run constantly with very little guidance. This optimizes manufacturing quantity. It likewise decreases the price per kilogram of filament made. The equipments are developed for simple operation and upkeep. Downtime is reduced considerably. Operators can rapidly change settings or do regular checks. Regular high quality is kept batch after set. This reliability constructs depend on with filament customers.

The applications for filament made on these lines are vast. Prototyping is a major use. PETG components are strong enough for useful screening. Several end-use items depend on PETG. It prevails in automotive parts needing durability. Digital units take advantage of PETG’s insulation and durability. Clinical gadget real estates make use of PETG because it can be disinfected. Food containers are made from PETG due to its safety profile. Artistic prints take advantage of PETG’s clarity and color alternatives. Educational designs make use of PETG for its simplicity of printing and toughness. Industrial tooling and jigs usually utilize PETG for its strength.

Company Profile

3D Printing Passion is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality 3D printing powder and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality 3D printing materials and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of PETG 3D printing filament extruder machinery production line

Here are 5 FAQs about PETG 3D printing filament extruder machinery production lines:

What’s the most important step before starting extrusion?

Dry the PETG pellets completely. PETG pellets absorb moisture from the air easily. Wet pellets cause bubbles and steam during extrusion. This ruins the filament quality. Use a good dryer hopper. Ensure pellets are dry before feeding them into the extruder.

What temperatures work best for PETG extrusion?

Maintain precise temperatures along the barrel. Different barrel zones need specific heat settings. PETG typically processes between 220°C and 250°C. Accurate temperature control is crucial. Wrong temperatures lead to poor melting, discoloration, or degradation. Monitor temperatures constantly.

How do we get consistent filament diameter?

Control the screw speed and haul-off speed carefully. These speeds determine the output rate and pull tension. Adjust the screw speed to match the desired output. Synchronize the haul-off speed perfectly. Wrong speeds cause thick or thin filament. Calibration is key.

How often should we clean the extruder?

Clean the machine regularly, especially after stopping production. Residual PETG can degrade inside the barrel. Degraded material causes clogs and contamination. Purge the system thoroughly when changing materials. Schedule deep cleaning based on production hours. Preventative maintenance avoids downtime.

What safety measures are essential?

Operators must wear heat-resistant gloves and safety glasses. The extruder barrel and die are extremely hot. Touching them causes severe burns. Ensure good ventilation around the machine. Fumes released during extrusion need proper extraction. Follow all lockout/tagout procedures during maintenance.

(PETG 3D printing filament extruder machinery production line)