Discover a professional 3D printing powder supplier

PRODUCT PARAMETERS

Description

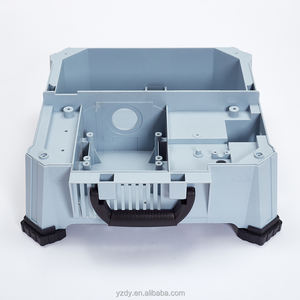

Overview of private label 3d printing selective laser sintering 3d printer

3D printing, also known as additive manufacturing, is a transformative technology that allows the creation of three-dimensional objects by depositing materials layer by layer based on digital designs. This process opens up a new world of possibilities in product design, customization, and production, revolutionizing various industries including healthcare, aerospace, automotive, consumer goods, and more.

Customization & Personalization: One of the key advantages of 3D printing is its ability to create highly customized products tailored to individual needs or preferences, from prosthetics to fashion accessories.

Complex Geometry: 3D printing excels at producing intricate shapes and geometries that would be extremely challenging or impossible to manufacture using conventional methods, such as internal lattice structures or organic forms.

Rapid Prototyping: It significantly speeds up the product development cycle by enabling designers and engineers to quickly produce physical prototypes for testing and refinement.

On-Demand Manufacturing: The technology supports small-batch or even one-off production runs economically, reducing the need for large inventories and allowing for just-in-time manufacturing.

Material Diversity: A wide range of materials can be used in 3D printing, including plastics, metals, ceramics, composites, and even biomaterials, each offering unique properties for specific applications.

Reduced Waste: As compared to subtractive manufacturing techniques, 3D printing only adds material where needed, leading to less waste and a more sustainable manufacturing process.

Features of private label 3d printing selective laser sintering 3d printer

Design Flexibility: The technology enables the realization of complex designs without the constraints of traditional manufacturing tools and molds.

Functional Integration: Parts can be designed with integrated features such as channels, cavities, or interlocking components, which can enhance functionality or simplify assembly.

Lightweight Structures: Advanced 3D printing techniques allow for the creation of lightweight yet strong structures through optimized designs and the use of lattice structures or composite materials.

Improved Performance: By precisely controlling material composition and structure, 3D printed parts can exhibit enhanced mechanical, thermal, or electrical properties.

Cost-Efficiency for Complexity: While 3D printing may not always compete with mass-production methods for simple parts, it becomes increasingly cost-effective as the complexity of the part increases.

Innovative Applications: From medical implants that match a patient’s anatomy perfectly to aerospace components that reduce weight and increase efficiency, 3D printing pushes the boundaries of what’s possible in product design and engineering.

(private label 3d printing selective laser sintering 3d printer)

Specification of private label 3d printing selective laser sintering 3d printer

This exclusive label discerning laser sintering printer constructs solid, practical parts. It uses a powerful laser. The laser precisely integrates great plastic powder layer by layer. The construct chamber is huge. It determines 300 x 300 x 300 mm. This dimension takes care of several common industrial parts. You can also fit numerous smaller sized things together in one print task.

The laser power is 50 watts. This power makes sure deep blend of the powder fragments. The result is thick parts. These components have superb mechanical buildings. They are solid and long lasting. The layer resolution is great. It goes down to 100 microns. This resolution produces smooth surfaces. Fine details appear plainly.

The maker works with numerous nylon powders. It deals with conventional PA12 perfectly. It additionally works well with PA11 and glass-filled nylons. Material changing is simple. The system consists of dual product feed cartridges. This configuration permits quick material swaps. Downtime is minimized. The integrated powder dealing with system is reliable. It recuperates unused powder instantly. This powder is filtered. Then it is fed back right into the process. Product waste is lessened.

Home heating is consistent. The construct chamber keeps a steady, heat. This temperature control is critical. It stops component warping. Regular component quality is achieved. The printer runs dependably. It runs continuously for long periods. Production timetables are met. The enclosed build area is secure. Operators are secured from powder and laser direct exposure. The user interface is easy. Device operation is simple to learn. Routine maintenance tasks are simple. Solution needs are marginal.

This SLS printer offers high performance. It delivers expert outcomes. Facility geometries are possible. Support frameworks are not needed throughout printing. The bordering powder supports the parts. Post-processing is primarily cleaning off excess powder. The parts await use quickly. This maker is a practical remedy for requiring applications. It appropriates for prototypes. It is likewise appropriate for end-use production parts.

(private label 3d printing selective laser sintering 3d printer)

Applications of private label 3d printing selective laser sintering 3d printer

Personal tag SLS 3D printing uses serious manufacturing benefits. Services utilize it for strong, functional prototypes. These models test components under actual tension. They seem like the end product. This speeds up advancement. Business discover issues early. Fixing them prices less later.

End-use production parts benefit too. SLS makes resilient products. Assume custom brackets, housings, or facility gears. The parts take care of warmth well. They stand up to chemicals. This makes them good for machines, devices, and even some cars and truck components. Low volume runs are economical. You stay clear of expensive tooling prices.

Complicated styles are easy with SLS. The printer builds layer by layer. Support structures aren’t needed during printing. Powder supports the part. This liberty permits intricate shapes. Inner channels or relocating settings up print in one go. Conventional methods deal with this. Developers have more choices.

Customization thrives with SLS printing. Each part can be distinct quickly. Dressmaker products for specific customers or requirements. Make personalized medical gadgets or bespoke sporting goods. Manufacturing ranges smoothly from one piece to hundreds. This fits on-demand production perfectly.

Private tag services let you use this. Put your brand on top notch SLS parts. You provide the capability without having the machine. Focus on layout and sales. Your clients get expert 3D published remedies. They see your name, not the modern technology behind it. This develops your brand value. It opens up new earnings streams.

Company Profile

3D Printing Passion is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality 3D printing powder and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality 3D printing materials and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of private label 3d printing selective laser sintering 3d printer

Here are 5 common questions about private label selective laser sintering (SLS) 3D printers:

What exactly can this SLS printer make? This machine builds strong, detailed parts using powdered nylon plastic. A powerful laser melts the powder layer by layer. It’s perfect for making functional prototypes, complex designs, and small batches of end-use parts. Think things like gears, hinges, enclosures, or custom fittings. The parts come out durable and ready for real-world use.

How does the private label part work? We supply the industrial-grade SLS printer. You choose your company’s name and logo. We put your branding directly on the machine. We put it on the software interface too. This makes the printer look like your own product. We handle all the manufacturing and setup with your branding.

What support comes with the machine? You get technical support directly from us. This covers machine operation, software issues, and routine maintenance. Training materials for your team are included. We provide spare parts. A warranty period is standard. This ensures your business can run smoothly and support your customers.

What materials can it use? Primarily, it uses nylon powders. Nylon 12 is the most common. Nylon 11 is another option. Sometimes glass-filled or mineral-filled nylons are available. These powders offer different properties. Some are stronger. Some are more flexible. Some handle heat better. We can advise on the best options for your specific needs.

How long does delivery take? Delivery times vary. They depend on order volume and your location. We build the machines to order with your branding. Production takes several weeks. Shipping and customs clearance add more time. We provide a specific estimated timeline after you place your order. We keep you updated throughout the process.

(private label 3d printing selective laser sintering 3d printer)