Discover a professional 3D printing powder supplier

PRODUCT PARAMETERS

Description

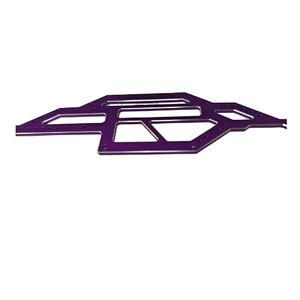

Overview of product Rapid Prototype custom high precision plastic model 3D printing service

3D printing, also known as additive manufacturing, is a transformative technology that allows the creation of three-dimensional objects by depositing materials layer by layer based on digital designs. This process opens up a new world of possibilities in product design, customization, and production, revolutionizing various industries including healthcare, aerospace, automotive, consumer goods, and more.

Customization & Personalization: One of the key advantages of 3D printing is its ability to create highly customized products tailored to individual needs or preferences, from prosthetics to fashion accessories.

Complex Geometry: 3D printing excels at producing intricate shapes and geometries that would be extremely challenging or impossible to manufacture using conventional methods, such as internal lattice structures or organic forms.

Rapid Prototyping: It significantly speeds up the product development cycle by enabling designers and engineers to quickly produce physical prototypes for testing and refinement.

On-Demand Manufacturing: The technology supports small-batch or even one-off production runs economically, reducing the need for large inventories and allowing for just-in-time manufacturing.

Material Diversity: A wide range of materials can be used in 3D printing, including plastics, metals, ceramics, composites, and even biomaterials, each offering unique properties for specific applications.

Reduced Waste: As compared to subtractive manufacturing techniques, 3D printing only adds material where needed, leading to less waste and a more sustainable manufacturing process.

Features of product Rapid Prototype custom high precision plastic model 3D printing service

Design Flexibility: The technology enables the realization of complex designs without the constraints of traditional manufacturing tools and molds.

Functional Integration: Parts can be designed with integrated features such as channels, cavities, or interlocking components, which can enhance functionality or simplify assembly.

Lightweight Structures: Advanced 3D printing techniques allow for the creation of lightweight yet strong structures through optimized designs and the use of lattice structures or composite materials.

Improved Performance: By precisely controlling material composition and structure, 3D printed parts can exhibit enhanced mechanical, thermal, or electrical properties.

Cost-Efficiency for Complexity: While 3D printing may not always compete with mass-production methods for simple parts, it becomes increasingly cost-effective as the complexity of the part increases.

Innovative Applications: From medical implants that match a patient’s anatomy perfectly to aerospace components that reduce weight and increase efficiency, 3D printing pushes the boundaries of what’s possible in product design and engineering.

(product Rapid Prototype custom high precision plastic model 3D printing service)

Specification of product Rapid Prototype custom high precision plastic model 3D printing service

Our Fast Prototype Custom High Accuracy Plastic Version 3D Printing Solution provides comprehensive plastic parts for markets needing accurate prototypes. The solution supports various engineering-grade products, including ABS, PLA, Nylon, and polycarbonate. These products use adaptability, toughness, or warm resistance based on project needs.

Components are developed using advanced 3D printing modern technologies like SLA, SLS, and FDM. Layer resolutions begin at 25 microns. This makes sure smooth surface areas and limited tolerances down to ± 0.1 mm. Complex geometries, slim walls, and fine information are attainable without extra tooling expenses.

Turnaround times range from 24 hours to 5 days. Speed depends upon component size, material, and design complexity. Submit your 3D data (STL or STEP style) for an immediate quote. Layout guidelines assist optimize designs for printability. Our team checks declare mistakes and suggests solutions before production.

Quality control consists of dimensional talk to calipers and CMM equipments. Surface area coatings can be matte, glossy, or textured. Post-processing options like fining sand, painting, or setting up are offered. Components are delivered in protective packaging to prevent damage.

The solution matches item programmers, engineers, and suppliers. Common applications consist of functional testing, principle validation, and pre-production samples. Industries like vehicle, clinical tools, and customer electronics make use of these prototypes for in shape checks or client presentations.

Modification covers product choice, shade matching, and mechanical buildings. Low-volume production runs (as much as 1,000 units) are possible. Mass orders get discounted rates. Technical support responses questions concerning style optimization or product efficiency.

Files are dealt with firmly with NDAs provided on demand. Worldwide delivery options consist of express distribution. Modifications are enabled if requirements transform mid-project. A devoted project supervisor tracks progress and shares updates.

Prices relies on material expenses, print time, and component volume. Transparent quotes damage down expenditures. No hidden costs apply. Settlement methods include credit cards and financial institution transfers. Thrill orders incur a 20% additional charge for prioritized scheduling.

Maintenance ideas extend prototype life-span. Avoid long term UV exposure for sure products. Shop components in completely dry problems to prevent bending. Compatibility data helps match products to specific ecological conditions.

(product Rapid Prototype custom high precision plastic model 3D printing service)

Applications of product Rapid Prototype custom high precision plastic model 3D printing service

Quick Model personalized high accuracy plastic version 3D printing services provide useful solutions for many markets. Designers and manufacturers use these services to create in-depth models rapidly. The procedure permits screening product designs prior to mass production. Errors can be fixed early, saving money and time. High precision makes sure components fit appropriately in last assemblies.

Item style companies benefit from reasonable designs for customer discussions. Physical models assist customers picture concepts far better than digital files. Changes can be made rapid based upon comments. This quickens decision-making and task timelines. Complicated geometries are attainable, which typical techniques might deal with.

Medical areas count on accurate 3D-printed versions for medical preparation. Custom reproductions of person composition let medical professionals practice treatments ahead of time. This minimizes dangers throughout procedures. Clinical device makers additionally examine models for fit and function. Biocompatible products guarantee safety in trial phases.

Engineers and construction companies make use of scaled versions to showcase building designs. Thorough minis highlight architectural functions and spatial designs. Customers get a clear concept of the final result. Modifications can be printed rapidly throughout layout evaluations. This keeps jobs on track without delays.

Educational institutions utilize 3D printing for training tools and research tasks. Pupils communicate with physical versions to recognize intricate theories. Personalized parts for lab equipment are made economically. Researchers model speculative tools without high expenses.

Hobbyists and musicians produce unique products utilizing this solution. Custom-made toys, cosplay accessories, or ornamental pieces are generated with professional surface. No minimum order size makes it available for tiny jobs. Strong, light-weight plastics ensure resilience while keeping information sharp.

The service supports various products like abdominal muscle, nylon, and resin. Different surface coatings are available, from smooth to distinctive. Fast turn-around times fulfill tight target dates. Advanced printers deal with detailed layouts without shedding information. Prices stay low as a result of efficient printing approaches.

Organizations of all dimensions utilize fast prototyping to remain affordable. It bridges the gap between idea and fact effectively. Flexibility in style versions fosters innovation. Reliable results aid teams move from concept to manufacturing with confidence.

Company Profile

3D Printing Passion is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality 3D printing powder and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality 3D printing materials and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of product Rapid Prototype custom high precision plastic model 3D printing service

What materials do you offer for 3D printing?

We use common plastics like ABS, PLA, Nylon, and resin. These materials are strong. They handle heat well. Some are flexible. Others are rigid. Tell us your project needs. We help pick the right material.

How fast can you deliver prototypes?

Most orders ship in 1-3 days. It depends on the design. Complex designs take longer. Small parts print faster. Large orders need extra time. We work quickly. Rush options exist for urgent jobs.

How precise are your 3D prints?

We achieve details as small as 0.1 mm. Layer heights go down to 0.05 mm. High-end printers ensure accuracy. Tight tolerances are possible. Parts fit together smoothly. We check dimensions carefully.

What file formats do you accept?

Send STL, OBJ, or STEP files. These formats work best. We review files first. Errors in the design cause printing issues. Our team fixes minor problems. We contact you if major changes are needed.

How much does it cost to print a prototype?

Prices start at $10 per part. Costs depend on size, material, and quantity. Larger parts use more material. Fancy finishes add cost. Bulk orders lower the price per unit. Request a quote for exact numbers.

(product Rapid Prototype custom high precision plastic model 3D printing service)