Discover a professional 3D printing powder supplier

PRODUCT PARAMETERS

Description

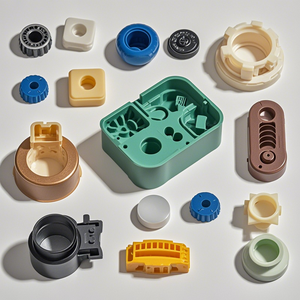

Overview of Provide 3D printing and rapid prototyping services for large-scale products and models

3D printing, also known as additive manufacturing, is a transformative technology that allows the creation of three-dimensional objects by depositing materials layer by layer based on digital designs. This process opens up a new world of possibilities in product design, customization, and production, revolutionizing various industries including healthcare, aerospace, automotive, consumer goods, and more.

Customization & Personalization: One of the key advantages of 3D printing is its ability to create highly customized products tailored to individual needs or preferences, from prosthetics to fashion accessories.

Complex Geometry: 3D printing excels at producing intricate shapes and geometries that would be extremely challenging or impossible to manufacture using conventional methods, such as internal lattice structures or organic forms.

Rapid Prototyping: It significantly speeds up the product development cycle by enabling designers and engineers to quickly produce physical prototypes for testing and refinement.

On-Demand Manufacturing: The technology supports small-batch or even one-off production runs economically, reducing the need for large inventories and allowing for just-in-time manufacturing.

Material Diversity: A wide range of materials can be used in 3D printing, including plastics, metals, ceramics, composites, and even biomaterials, each offering unique properties for specific applications.

Reduced Waste: As compared to subtractive manufacturing techniques, 3D printing only adds material where needed, leading to less waste and a more sustainable manufacturing process.

Features of Provide 3D printing and rapid prototyping services for large-scale products and models

Design Flexibility: The technology enables the realization of complex designs without the constraints of traditional manufacturing tools and molds.

Functional Integration: Parts can be designed with integrated features such as channels, cavities, or interlocking components, which can enhance functionality or simplify assembly.

Lightweight Structures: Advanced 3D printing techniques allow for the creation of lightweight yet strong structures through optimized designs and the use of lattice structures or composite materials.

Improved Performance: By precisely controlling material composition and structure, 3D printed parts can exhibit enhanced mechanical, thermal, or electrical properties.

Cost-Efficiency for Complexity: While 3D printing may not always compete with mass-production methods for simple parts, it becomes increasingly cost-effective as the complexity of the part increases.

Innovative Applications: From medical implants that match a patient’s anatomy perfectly to aerospace components that reduce weight and increase efficiency, 3D printing pushes the boundaries of what’s possible in product design and engineering.

(Provide 3D printing and rapid prototyping services for large-scale products and models)

Specification of Provide 3D printing and rapid prototyping services for large-scale products and models

We provide 3D printing and quick prototyping solutions tailored for large-scale products and versions. Our capacities cover industrial-grade additive manufacturing services designed to handle complex tasks requiring accuracy and durability. We utilize sophisticated technologies like FDM, SLS, and shanty town to produce parts with high accuracy and architectural stability. Materials offered include design plastics, resins, carbon fiber composites, and metal alloys, making sure compatibility with varied practical and visual demands.

Our devices supports construct volumes up to 1.5 meters in size, accommodating large parts without endangering information. This makes us a sensible choice for industries such as aerospace, automobile, style, and home entertainment. Fast turnaround times are prioritized. Models can be provided within days, reducing hold-ups in item development cycles.

Quality assurance is integral to our process. Each print undergoes strenuous inspection for dimensional precision, surface area finish, and mechanical efficiency. Post-processing options like fining sand, paint, and setting up are available to fulfill specific client demands. Customization is straightforward. Clients give CAD data or layout concepts. Our group handles documents optimization, product selection, and manufacturing planning to make certain feasibility and cost-efficiency.

Cost-effective scaling is possible with bulk manufacturing options. We keep competitive rates for both tiny sets and high-volume orders. Technical support is supplied at every phase, from first assessment to final distribution. Experienced designers are offered to troubleshoot layout difficulties and suggest solutions for optimum outcomes.

Toughness and performance are stabilized in every project. Parts endure cardiovascular test, environmental exposure, and real-world application checks. Privacy contracts shield client IP. Data security methods make sure documents stability and task privacy.

Sustainability techniques lessen waste. Recyclable materials and energy-efficient systems are prioritized where feasible. Neighborhood manufacturing hubs minimize shipping distances and carbon impacts. Global logistics partners take care of reputable delivery for international customers.

Customers accessibility real-time updates on task standing with an on the internet portal. Devoted account supervisors enhance communication. Modifications are accommodated swiftly to align with developing style needs. Our focus continues to be on merging speed, precision, and cost to support innovation across sectors.

(Provide 3D printing and rapid prototyping services for large-scale products and models)

Applications of Provide 3D printing and rapid prototyping services for large-scale products and models

3D printing and fast prototyping solutions aid services produce large items and versions efficiently. These innovations are made use of in several industries to conserve time, lower prices, and boost design accuracy. Companies count on them for testing ideas, addressing problems, and providing custom-made options quickly.

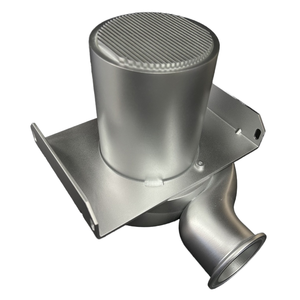

The automobile industry uses 3D printing to make model components for autos, vehicles, and equipment. Engineers check designs for engines, body panels, and interior components before full production. This approach cuts development time and lets groups take care of issues early. Custom devices and jigs are additionally printed to quicken assembly lines.

Aerospace business construct light-weight, complicated parts for airplane and satellites with these solutions. Prototyping assists verify layouts for strength, warm resistance, and air movement effectiveness. Massive versions of wings or bodies are printed to examine fit and function. This reduces material waste and makes certain safety in vital systems.

Construction firms print outlined scale versions of structures, bridges, and infrastructure tasks. Designers show clients sensible prototypes to imagine final structures. Professionals examination how products act under stress or climate condition. Customized parts like brackets or ports are made on-site to avoid delays.

Entertainment and marketing sectors produce life-sized props, statues, and presents for occasions or movies. Quick prototyping turns electronic styles right into physical objects quickly. Stage collections, advertising products, and art setups are generated with detailed information. This flexibility supports tight deadlines and distinct imaginative demands.

Medical areas make use of 3D printing for big physiological models to plan surgical procedures or train staff. Prosthetics and orthopedic devices are customized to fit people flawlessly. Researchers prototype lab devices and real estate for clinical gadgets to improve performance.

Manufacturers take on these services to simplify manufacturing. Mold and mildews, patterns, and themes are published for spreading or molding processes. Busted machinery parts are duplicated promptly to decrease downtime. Personalized packaging solutions safeguard large products throughout shipping.

Education and learning institutions print oversized designs for training facility ideas. Students interact with 3D maps, molecular structures, or historic artifacts to enhance discovering. Engineering teams collaborate on jobs making use of responsive models for far better comments.

These applications show how 3D printing and rapid prototyping adjust to varied demands. Companies address troubles quicker, experiment openly, and fulfill client assumptions without high expenses. The innovation evolves to take care of larger projects and tougher materials, opening up new opportunities throughout industries.

Company Profile

3D Printing Passion is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality 3D printing powder and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality 3D printing materials and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Provide 3D printing and rapid prototyping services for large-scale products and models

What materials can you use for large-scale 3D printing?

We work with plastics, metals, and resins. These materials handle heat, pressure, and wear. Plastics like ABS and nylon are common for lightweight parts. Metals like aluminum and titanium suit heavy-duty industrial uses. Resins work for detailed models needing smooth surfaces. We pick materials based on your project’s needs.

How big can the printed products be?

Our printers handle parts up to 10 feet in length. Bigger items get split into sections. We assemble them after printing. This keeps details precise. We check structural strength during assembly.

How fast is rapid prototyping with your services?

Most prototypes take 3-7 days. Complexity and size affect timelines. Simple designs finish faster. We update you if delays happen. Rush options exist for urgent projects.

What makes 3D printing cost-effective for large models?

Traditional methods need expensive molds or setups. 3D printing skips these steps. Less material gets wasted. Design changes are easy without new tools. Costs stay predictable even for one-off projects.

Do you help with design adjustments before printing?

Yes. Our team reviews your files for errors. We suggest fixes for printability or strength. We tweak wall thickness, support structures, or material use. This ensures the final product works as intended.

(Provide 3D printing and rapid prototyping services for large-scale products and models)