Discover a professional 3D printing powder supplier

PRODUCT PARAMETERS

Description

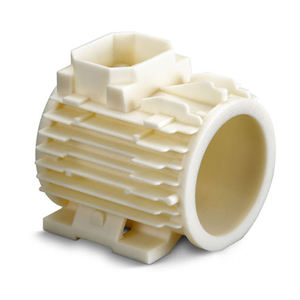

Overview of Sheet metal machining rapid prototype fabrication 3d printing modeling

3D printing, also known as additive manufacturing, is a transformative technology that allows the creation of three-dimensional objects by depositing materials layer by layer based on digital designs. This process opens up a new world of possibilities in product design, customization, and production, revolutionizing various industries including healthcare, aerospace, automotive, consumer goods, and more.

Customization & Personalization: One of the key advantages of 3D printing is its ability to create highly customized products tailored to individual needs or preferences, from prosthetics to fashion accessories.

Complex Geometry: 3D printing excels at producing intricate shapes and geometries that would be extremely challenging or impossible to manufacture using conventional methods, such as internal lattice structures or organic forms.

Rapid Prototyping: It significantly speeds up the product development cycle by enabling designers and engineers to quickly produce physical prototypes for testing and refinement.

On-Demand Manufacturing: The technology supports small-batch or even one-off production runs economically, reducing the need for large inventories and allowing for just-in-time manufacturing.

Material Diversity: A wide range of materials can be used in 3D printing, including plastics, metals, ceramics, composites, and even biomaterials, each offering unique properties for specific applications.

Reduced Waste: As compared to subtractive manufacturing techniques, 3D printing only adds material where needed, leading to less waste and a more sustainable manufacturing process.

Features of Sheet metal machining rapid prototype fabrication 3d printing modeling

Design Flexibility: The technology enables the realization of complex designs without the constraints of traditional manufacturing tools and molds.

Functional Integration: Parts can be designed with integrated features such as channels, cavities, or interlocking components, which can enhance functionality or simplify assembly.

Lightweight Structures: Advanced 3D printing techniques allow for the creation of lightweight yet strong structures through optimized designs and the use of lattice structures or composite materials.

Improved Performance: By precisely controlling material composition and structure, 3D printed parts can exhibit enhanced mechanical, thermal, or electrical properties.

Cost-Efficiency for Complexity: While 3D printing may not always compete with mass-production methods for simple parts, it becomes increasingly cost-effective as the complexity of the part increases.

Innovative Applications: From medical implants that match a patient’s anatomy perfectly to aerospace components that reduce weight and increase efficiency, 3D printing pushes the boundaries of what’s possible in product design and engineering.

(Sheet metal machining rapid prototype fabrication 3d printing modeling)

Specification of Sheet metal machining rapid prototype fabrication 3d printing modeling

Sheet metal machining forms metal sheets into components. We cut, bend, and punch steel. This makes strong, resilient parts. Believe brackets, units, or chassis parts. We make use of precise machines like laser cutters and press brakes. Accuracy is vital for components suitable with each other right. Sheet steel is excellent for final products or sturdy models. It handles high quantities well once the tooling is set. Configuration spends some time though.

Fast prototype construction gets physical models quickly. We develop examples quickly for screening and style checks. This phase finds problems early. Repairing issues now saves cash later on. We make use of different techniques depending upon the need. Rate is the primary objective below. Getting a part in your hands quickly assists the style procedure. You see and feel the item idea swiftly. This beats simply checking out a computer design.

3D printing modeling builds parts layer by layer. No complicated molds or tools are needed upfront. This is perfect for extremely complicated shapes. Developers have a lot more liberty. We make in-depth versions directly from digital data. It’s suitable for small sets or unique items. Products include plastics, resins, and often metals. Turnaround is frequently extremely fast. The surface coating differs by innovation. Some components need extra smoothing. 3D printing succeeds at aesthetic models and practical testing versions. Strength depends on the material and printing technique. It enhances standard machining.

(Sheet metal machining rapid prototype fabrication 3d printing modeling)

Applications of Sheet metal machining rapid prototype fabrication 3d printing modeling

Sheet metal machining fast model construction combines fast approaches with precision metalworking. It aids firms check layouts promptly before complete production. This approach conserves cash and time. Sheet metal machining cuts, bends, and shapes steel sheets accurately. It holds limited tolerances needed for functional models. Parts made in this manner carefully imitate last production pieces. They can be evaluated under real-world problems. Designers verify if a design functions right. They check fit, kind, and function early. Locating issues early protects against costly mistakes later on. Taking care of concerns is much cheaper at this stage.

3D printing modeling adds an additional layer of speed. Developers produce complex digital versions fast. 3D printers turn these models into physical objects rapidly. Plastic or material models offer a quick aesthetic check. They assist confirm forms and assembly ideas. For parts needing metal toughness, sheet steel machining takes control of. It develops durable, practical models from real sheet steel. Both techniques work well with each other. A rough 3D published version might be used first. Then an exact sheet steel prototype adheres to for rigorous screening. This hybrid method speeds up advancement cycles substantially.

Industries like automotive, aerospace, and electronic devices rely on this. They require to innovate regularly. Obtaining prototypes quick is important. Sheet metal prototypes can be used in wind tunnels or engine areas. They hold up against warmth and anxiety like final components. Clinical gadget manufacturers utilize it for checking medical tools. Consumer electronics companies examine enclosures and heat sinks. Industrial tools building contractors examination braces and chassis components. This method bridges the gap between electronic design and automation. It guarantees the end product does dependably.

Company Profile

3D Printing Passion is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality 3D printing powder and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality 3D printing materials and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of Sheet metal machining rapid prototype fabrication 3d printing modeling

What sheet metal prototyping options exist?

You have choices. CNC machining cuts precise parts from sheet metal. Laser cutting works well for flat designs. 3D printing builds models layer by layer using plastic or metal powder. Pick CNC or laser for strong, functional metal prototypes. Use 3D printing for complex shapes or fast early models.

What materials are common?

Steel, aluminum, and stainless steel are standard. Steel is strong but heavy. Aluminum is lighter and resists rust well. Stainless steel handles tough conditions and corrosion. The best material depends on your part’s job, strength needs, and cost.

How fast is turnaround?

Speed varies. Simple laser-cut parts might take a few days. CNC machining usually needs several days or a week. Metal 3D printing is slower, often taking one to two weeks. Complexity and order size affect the time. We aim for the fastest possible speed without losing quality.

Why choose machining over 3D printing?

Machined parts are stronger. They use real sheet metal. This gives properties like the final product. Machining handles tight tolerances better. It’s cost-effective for simpler shapes. 3D printing suits very complex internal features machining cannot easily make.

What design limits should I know?

Machining needs tool access. Avoid impossible undercuts. Sharp inside corners are hard. Minimum hole sizes and wall thicknesses exist. Bending requires specific bend radii. 3D printing has limits on overhangs and minimum feature size. Discuss your design early for best results.

(Sheet metal machining rapid prototype fabrication 3d printing modeling)