Discover a professional 3D printing powder supplier

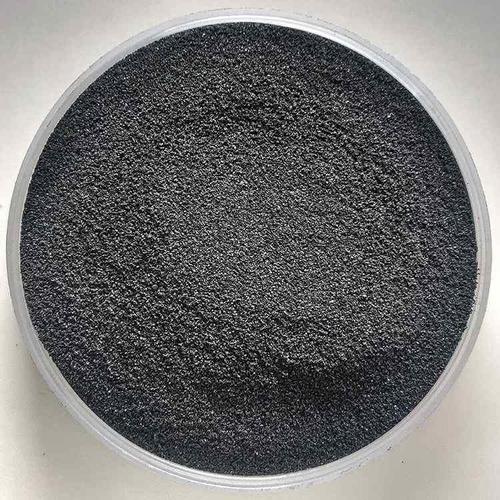

Cobalt-based 3D Printing Powder

Riton slm laser 3d printer metal cobalt chrome, stainless steel 3d printed jewellery 3d printer

Co Spherical Cobalt Powder Cobalt Powder Hydrogen Storage Alloys Material High Pure 3D Printing Metal Co Powder Carbide Factory

14~45um Audental Metal powder SLM DMLS 3d metal printing CoCr CoCrMo CoCrW CoCrMoW Medical Cobalt chromium alloy powder

Riton SLM 3d printer printing titanium, cobalt chrome, stainless steel metal powder dental laboratory metal 3d printer

Industrial SLM 3d printer printing titanium, cobalt chrome, stainless steel metal powder dental laboratory metal 3d printer

Cobalt Chrome Alloy Powder for 3D Printing( CoCrMo CoCrW)

99.9% Co powder metal cobalt powder atomized spherical cobalt powder Co99.9

INONE 3D printing dental metal alloy powder CoCrMo CoCrW cobalt chromium tungsten alloy powder

M140C SLM 3d printer printing titanium, cobalt chrome, stainless steel metal powder dental laboratory metal 3d printer

Affordable CoCrMo powder cobalt-chromium alloys for additive manufacturing

Riton Dual-150 digital printing machine dental cobalt chrome powder 3d printer

Buy 3D printing powder 99.9%Min Spherical Cobalt Co Refractory Metal Powder

Introduction to cobalt-based 3D printing powder

Cobalt-based 3D printing powder is a metal powder material used for additive manufacturing (such as SLM, EBM, etc.), mainly composed of alloy elements such as cobalt, chromium, and molybdenum. Its excellent high temperature resistance, corrosion resistance, and mechanical properties make it a key material in the aerospace, medical, and energy fields.

Specifications of cobalt-based 3D printing powder

| Parameter | Typical Value |

|---|---|

| Composition | CoCrMo, CoCrW, CoNiCrMo, etc. |

| Particle Size | 15-45 μm (D50) |

| Density | 8.3-9.2 g/cm³ |

| Melting Point | 1350-1500°C |

| Oxygen Content | ≤0.1 wt% |

| Flowability | ≤25 s/50g (Hall Flowmeter) |

| Standards | ASTM F75, ISO 5832-12 |

Characteristics of cobalt-based 3D printing powder

High heat resistance: suitable for high temperature environments (such as turbine blades, engine parts).

Biocompatibility: Some cobalt-chromium alloys can be used for medical implants (such as prostheses, dental restorations).

High strength and wear resistance: suitable for high mechanical stress scenarios.

Oxidation resistance: excellent performance in corrosive environments.

Good printability: good powder fluidity and high molding accuracy.

Application of cobalt-based 3D printing powder

Aerospace: gas turbine blades, rocket nozzles.

Medical: artificial joints, dental implants.

Energy: nuclear reactor components, oil drilling tools.

Mold manufacturing: high-durability injection molds.

Company Profile

3D Printing Passion is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality 3D printing powder and relative products.The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.If you are looking for high-quality 3D printing materials and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs about Cobalt-based 3D Printing Powders

Q: What are the main components of cobalt-based powders?

A: Usually cobalt, chromium, molybdenum, and may contain tungsten or nickel.

Q: Does it support all 3D printing technologies?

A: Mainly used for laser/electron beam melting (SLM/EBM), not suitable for FDM.

Q: Does medical use require special treatment?

A: It must comply with biocompatibility standards such as ISO 5832 or ASTM F75.

Q: What are the advantages compared to nickel-based alloys?

A: Higher wear resistance and high temperature stability, but the cost may be higher.

Q: How to recycle the powder?

A: Unmelted powder can be sieved and reused, and the oxygen content needs to be controlled.